Real-time monitoring system and monitoring method for pipeline welding conditions

A real-time monitoring and welder technology, applied in welding equipment, auxiliary welding equipment, manufacturing computing systems, etc., can solve the problems that welding quality cannot be monitored in real time, affecting pipeline welding quality, etc., to meet the needs of online real-time monitoring and abnormal working conditions. Alarms, reduce major quality problems, and time-sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

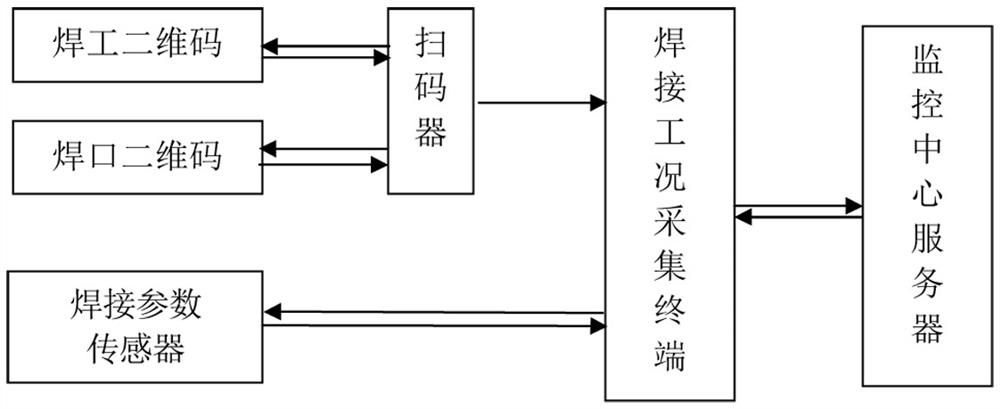

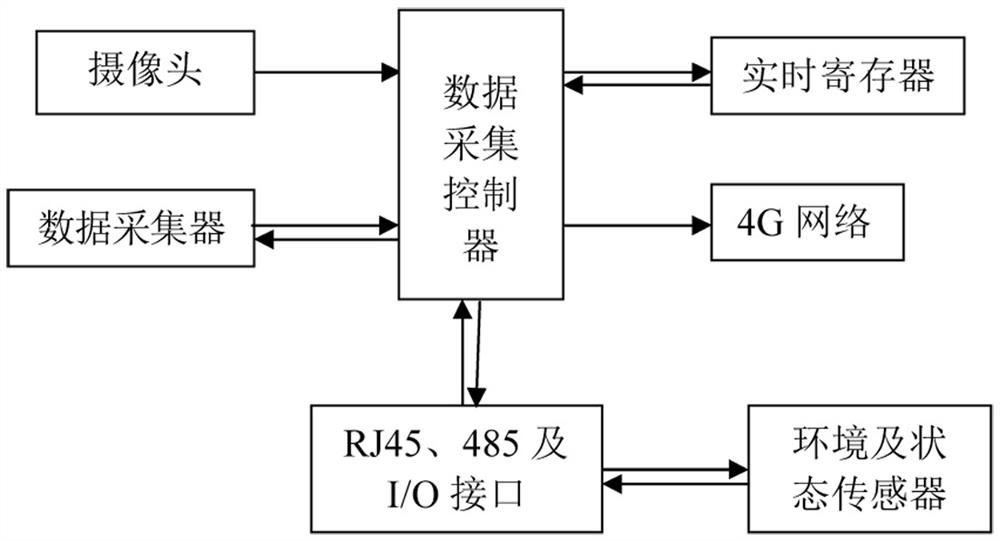

[0038] like figure 1As shown, the real-time monitoring system for pipeline welding conditions of the present invention includes welding parameter sensors, welder two-dimensional codes, welding port two-dimensional codes, code scanners, welding condition collection terminals, monitoring center servers and other parts. The welding condition collection terminal is connected with the barcode scanner and the welding parameter sensor by wire, and the welding condition collection terminal is connected with the monitoring center server by wireless transmission through the network.

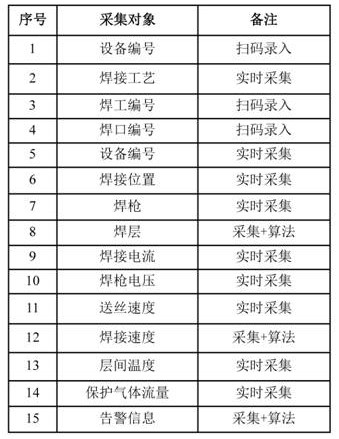

[0039] The welding parameter sensor is an integral part of the existing automatic welding machine, which can collect the working parameters of the welding machine including welding current, welding voltage, wire feeding speed and ambient temperature and humidity generated by the automatic welding machine in real time. Welder QR code is compiled from comprehensive information including welder's serial numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com