Power semiconductor module cooling device and power semiconductor module

A technology of power semiconductors and cooling devices, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of reduced production efficiency, many failure points, and reduced cooling effect, so as to improve assembly efficiency and assembly The effect of simple process and reduced failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

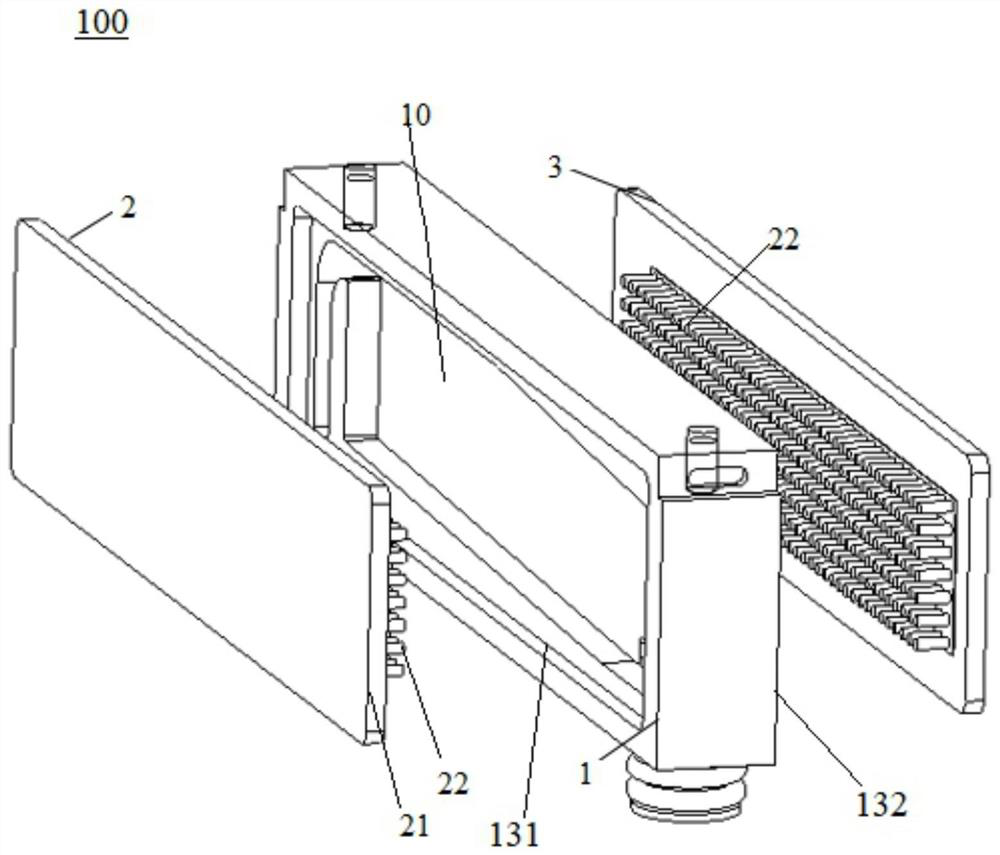

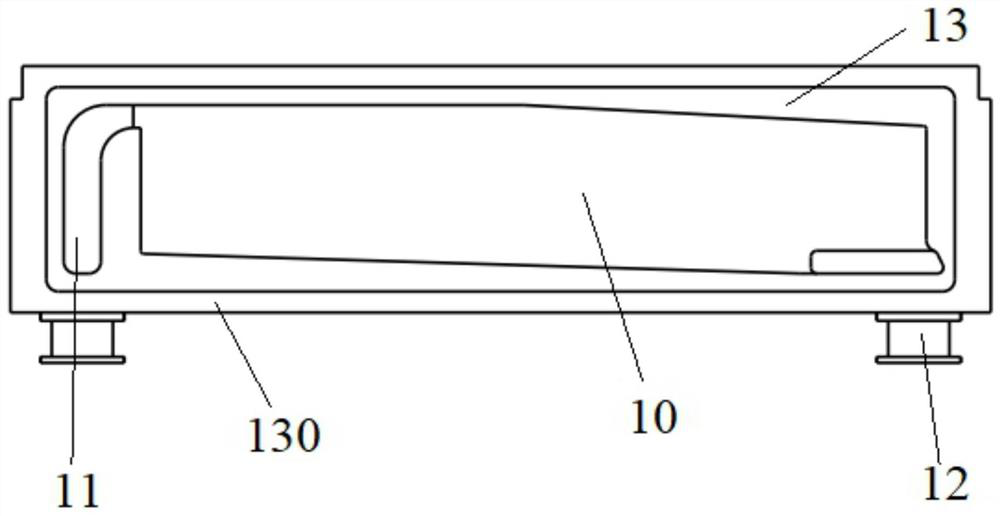

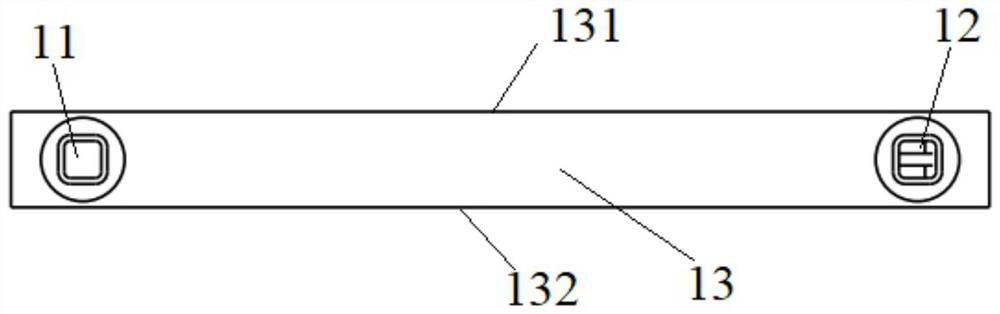

[0027] Embodiments of the present invention: as Figure 1-4 As shown, a power semiconductor module cooling device is disclosed, including: a cooling housing 1 having a heat exchange cavity 10 and side walls arranged on the front and rear sides of the cooling housing 1 and forming the heat exchange cavity 10 The front cooling plate 2 and the rear cooling plate 3. The cooling shell 1 also has a water inlet channel 11 and a water outlet channel 12 communicating with the cooling cavity 10; the front side heat sink 2 is tightly connected with the cooling shell 1 through integral welding, and the rear The side radiator plate 3 is tightly connected to the cooling shell 1 through integral welding.

[0028] In this embodiment, the water inlet channel 11, the heat exchange chamber 10 and the water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com