Transmission, driving, sterile instrument box assembly, surgical instrument system and robot

一种传动组件、手术器械的技术,应用在医疗器械领域,能够解决器械结构复杂化、精度误差、耦合失效等问题,达到提高轴向尺寸利用率、提高使用寿命、减小轴向尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

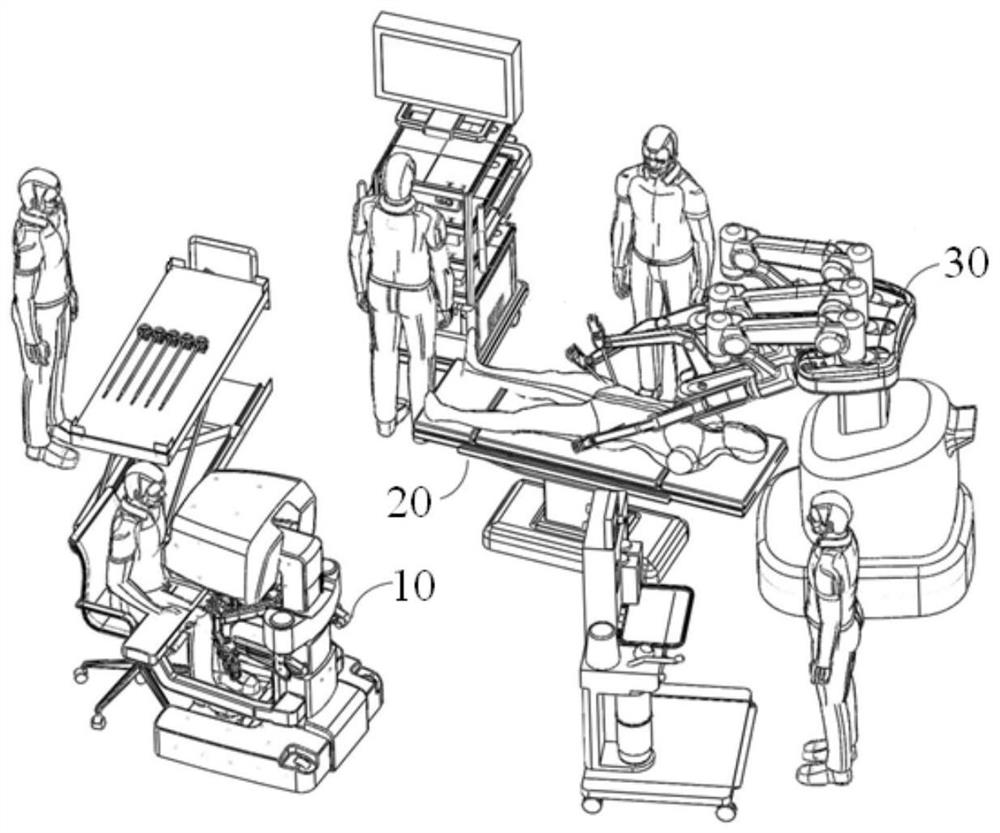

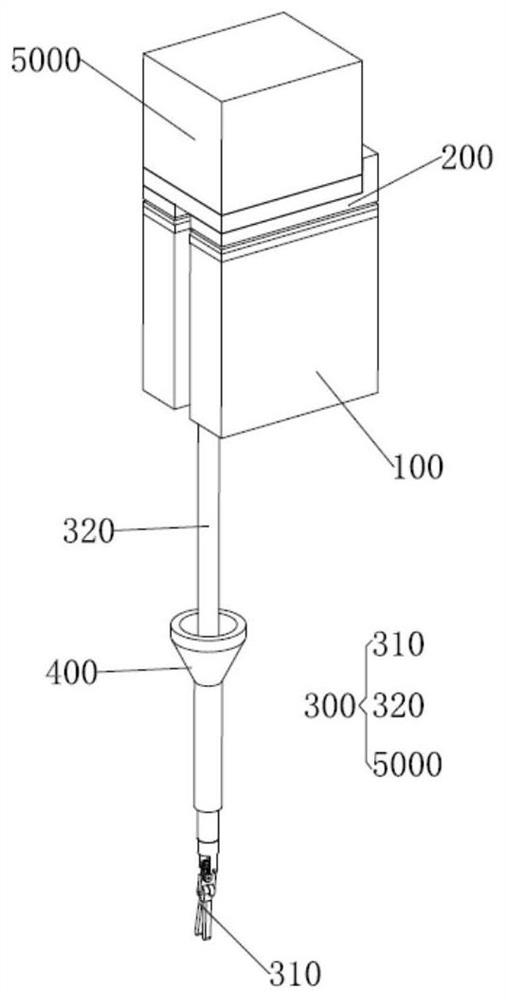

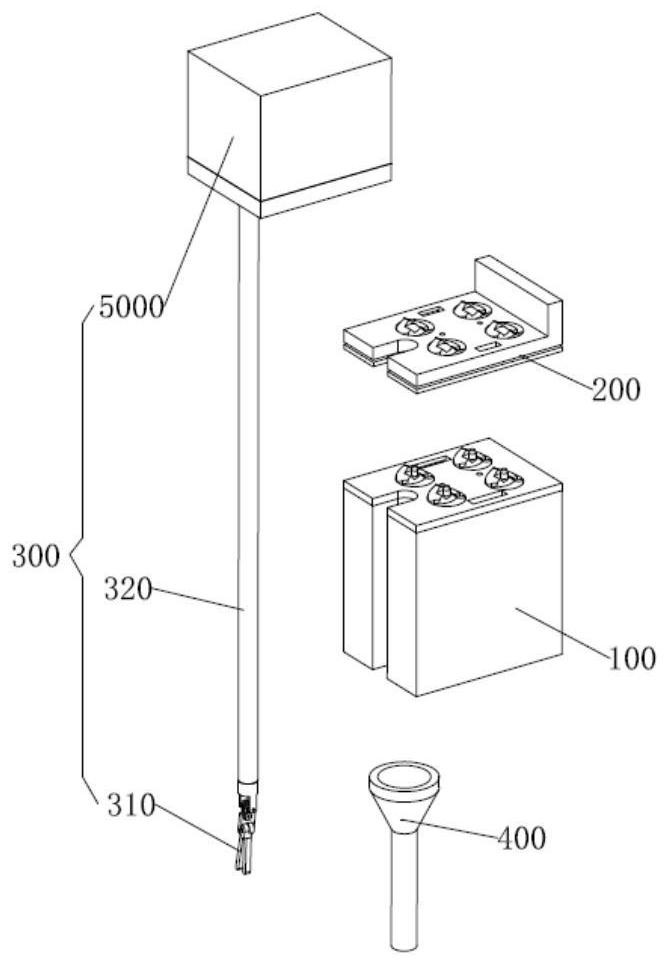

[0190] In order to make the purpose, advantages and features of the present invention clearer, a transmission, drive, sterile instrument case assembly, surgical instrument system, and robot proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0191] As used in this specification and the appended claims, the singular forms "a", "an" and "the" include plural referents and the plural form "a plurality" includes "two or more". Unless the content clearly states otherwise. As used in this specification and the appended claims, the term "or" is generally used in its sense including "and / or", unless the content clearly indicates otherwise, and the terms "installed", "connected" 2. "Connection" shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com