System and method for efficiently synthesizing glycolide

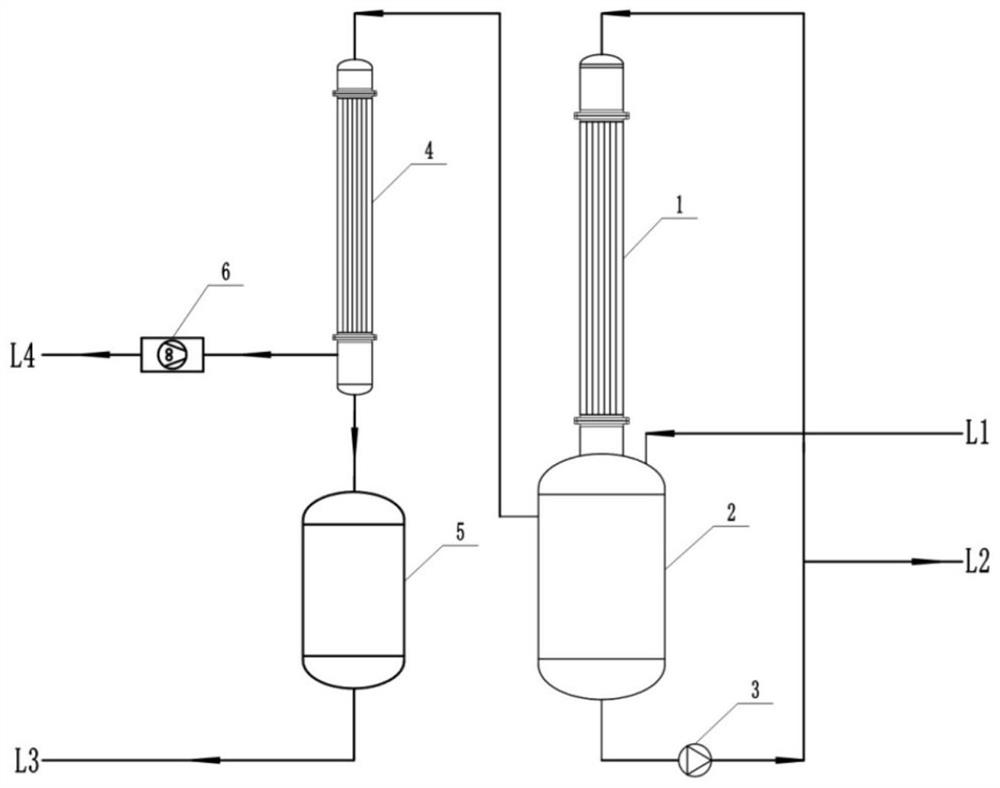

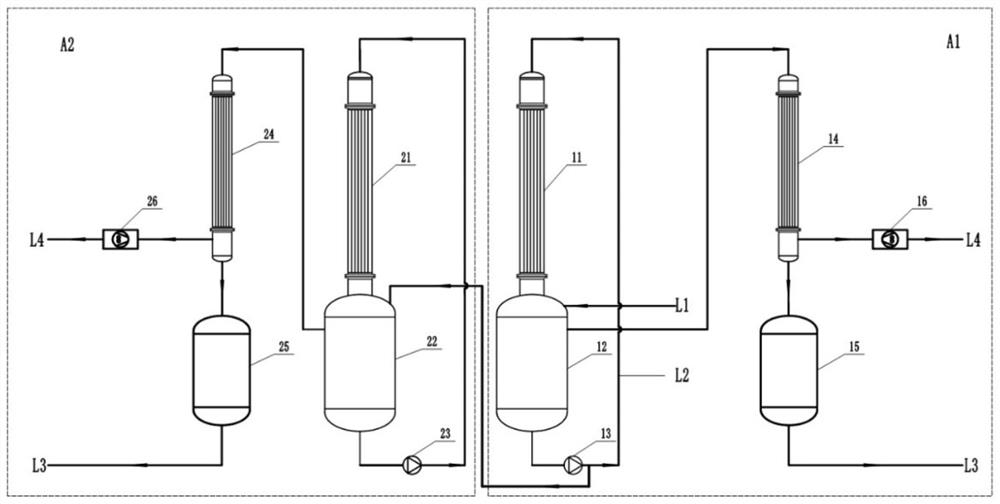

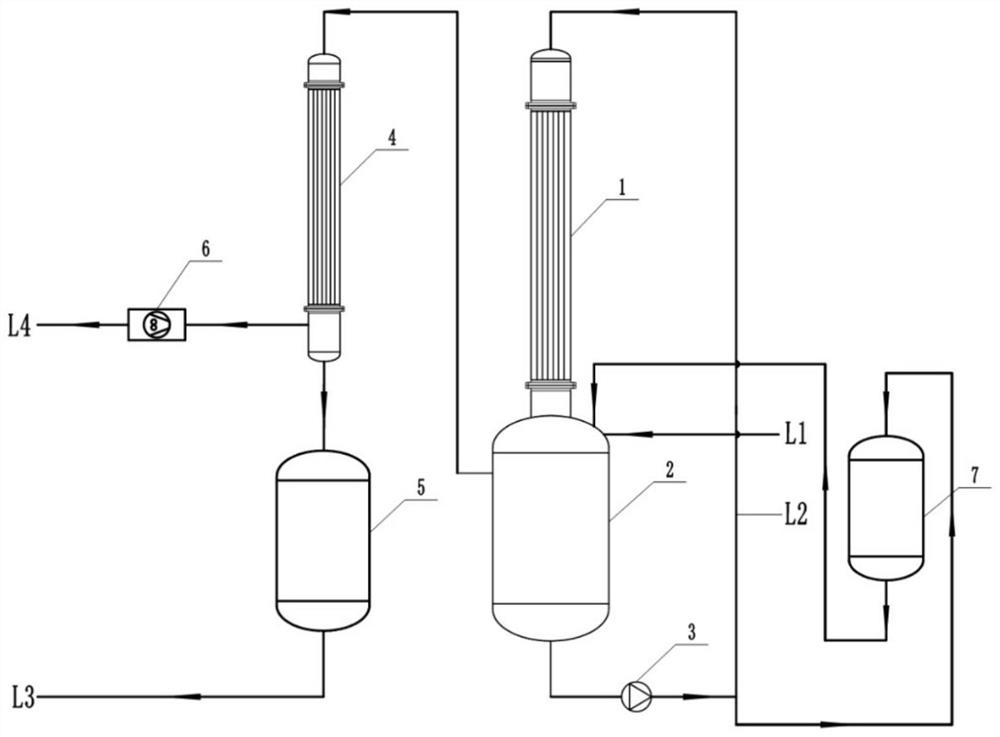

A glycolide, high-efficiency technology, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve the problem of high gas phase mass transfer resistance and reaction pressure drop High, low product yield and other issues, to achieve the effect of low mass transfer resistance, reduce production costs, and increase product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] In this embodiment, glycolic acid is used as a raw material, and a continuous system for glycolide synthesis is used to produce glycolide, as follows:

[0076] Add 80kg of molten glycolic acid to the gasification chamber of the first set of falling film reaction unit of the system, and add 1wt% of antimony oxide as a dehydration catalyst, open the cooling and heating medium temperature control system of the falling film reactor, and open the circulation pump at the same time to make the material Circular flow. Under the conditions of controlling the reaction temperature to 180° C. and the reaction pressure to 3000 Pa, the reaction was carried out for 3 hours. Water was continuously produced during the reaction. After reacting for 3 hours, glycolic acid was polycondensed and dehydrated to obtain glycolic acid oligomers, and the molecular weight of glycolic acid oligomers was about 2680.

[0077] The glycolic acid oligomer enters the second set of falling film reaction ...

Embodiment 2

[0079] In this embodiment, methyl glycolate is used as a raw material, and a continuous type glycolide synthesis system is used to produce glycolide, as follows:

[0080] Join the 100kg methyl glycolate of melting into the vaporization chamber of the first cover falling film reaction unit, and add dealcoholization catalyst tetraethyl titanate 1.5wt%, open the cold and hot medium temperature control system of falling film reactor, simultaneously Turn on the circulating pump to circulate the material through the whole system. Under the conditions of controlling the reaction temperature to 200° C. and the reaction pressure to 1000 Pa, the reaction was carried out for 5 hours. Methanol was continuously produced during the reaction. After reacting for 5 hours, methyl glycolate was polycondensed and dealcoholized to obtain glycolic acid oligomers, and the molecular weight of glycolic acid oligomers was about 3000.

[0081] The glycolic acid oligomer enters the second set of fallin...

Embodiment 3

[0083] In this embodiment, glycolic acid is used as a raw material, and a system for discontinuous glycolide synthesis is used to produce glycolide, as follows:

[0084] Add glycolic acid to the vaporization chamber of the system at 10kg / h, and add 1wt% of antimony oxide as a dehydration catalyst, open the cooling and heating medium temperature control system of the falling film reactor, and open the circulation pump at the same time, so that the material circulates in the whole system . Control the reaction temperature at 130°C and the reaction pressure at 5000Pa. After 8 hours of reaction, the glycolic acid oligomers are extracted and put into the intermediate storage tank to keep the temperature for use. The gaseous water generated during the reaction is condensed by the condenser and then enters the collection tank. , discharged from the condensate discharge line. Glycolic acid oligomers are obtained by polycondensation and dehydration of glycolic acid, and the molecular ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap