Rice flour integrated processing equipment

A technology for processing equipment and rice flour, applied in the field of integrated rice flour processing equipment, can solve the problems of low work efficiency, difficult to remove impurities, long time consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

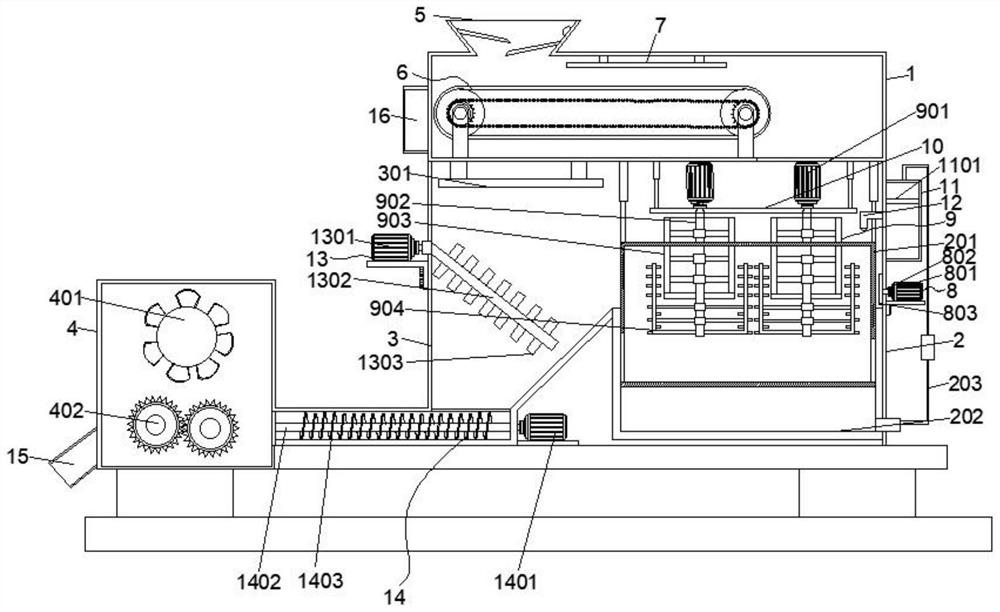

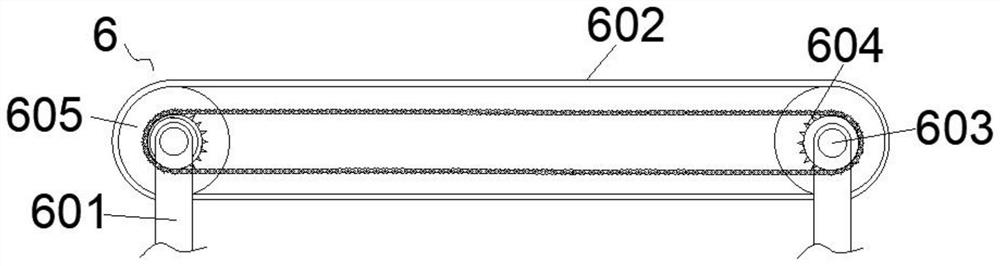

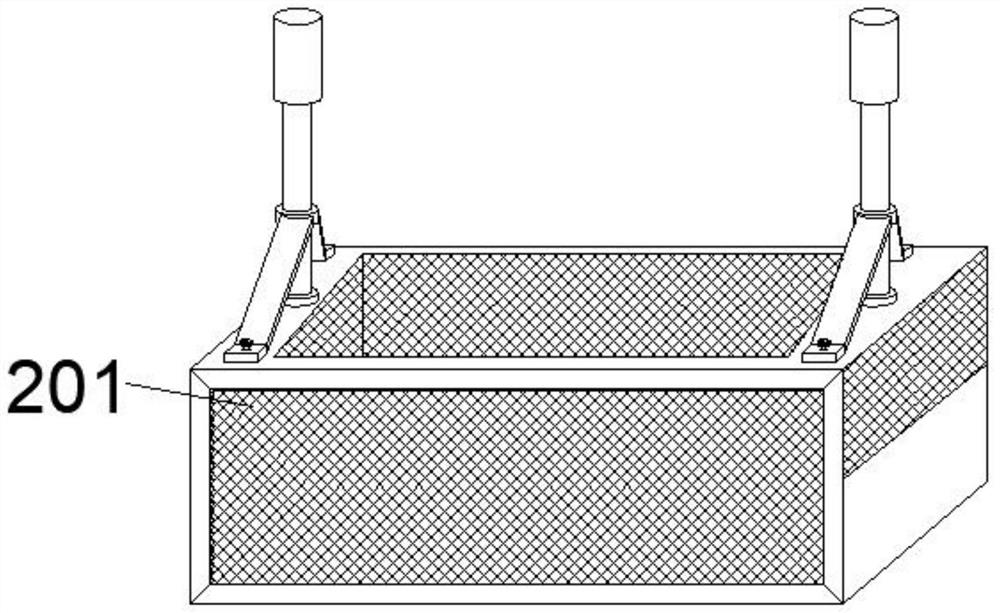

[0028] see Figure 1-4 As shown, the present invention provides a technical solution of integrated rice flour processing equipment: a kind of integrated rice flour processing equipment, comprising a delivery box 1, a cleaning box 2, a drying box 3 and a crushing box 4, the delivery box 1 A feed hopper 5 is arranged on the top of the conveyor box 1, and a conveying mechanism 6 is arranged inside the conveying box 1, and the conveying mechanism 6 includes a support plate 601, a conveying belt 602, a rotating shaft 603, a gear 604, a conveying roller 605 and a driving motor. The top of the delivery box 1 is fixedly equipped with a disinfection lamp 7, the disinfection lamp 7 is located above the conveyor belt 602, the bottom of the delivery box 1 is provided with an opening, and the cleaning box 2 is arranged on the bottom of the delivery box 1. The inner cavity of the conveying box 1 and the cleaning box 2 is connected, and the interior of the cleaning box 2 is provided with a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com