Patents

Literature

36results about How to "Prevent affecting processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel pipe end sealing device and using method

PendingCN111153001APhosphating effect will not be reducedReduce deliveryMetallic material coating processesPackagingButt jointElectric machinery

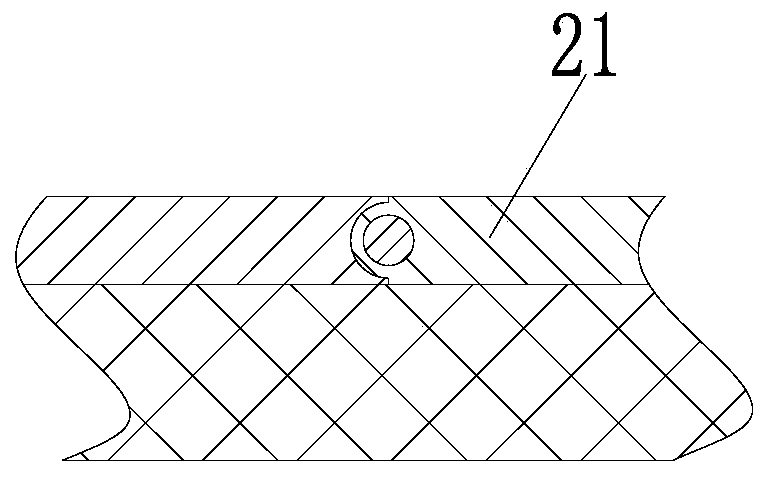

The invention discloses a steel pipe end sealing device, and relates to the technical field of machining. The steel pipe end sealing device comprises a rack arranged on a plane and a conveying devicearranged inside the rack, wherein the conveying device comprises a sliding base arranged inside the rack, a clamping wheel plate arranged inside the rack and a fixing device arranged above the rack, the fixing device comprises a placing frame arranged above the rack, telescopic motors arranged on the placing frame, a fixing base arranged inside the placing frame, a semicircular arc-shaped surfaceis formed in the fixing base and a pushing and pressing device arranged on one side of the rack and fixedly connected with the rack, and the pushing and pressing device comprises a butt joint pipe arranged on the outer side of the rack, an end sealing cover arranged inside the butt joint pipe and a pushing and pressing air cylinder arranged on one side of the butt joint pipe. According to the steel pipe end sealing device and the using method, the problems that high firmness cannot be kept and the sleeving efficiency is low when an end sealing sleeve manually sleeves an end port of a steel pipe, and the end sealing sleeve is easily caused to fall off are prevented.

Owner:ZHANGJIAGANG CITY SHENGDINGYUAN PIPE MAKING

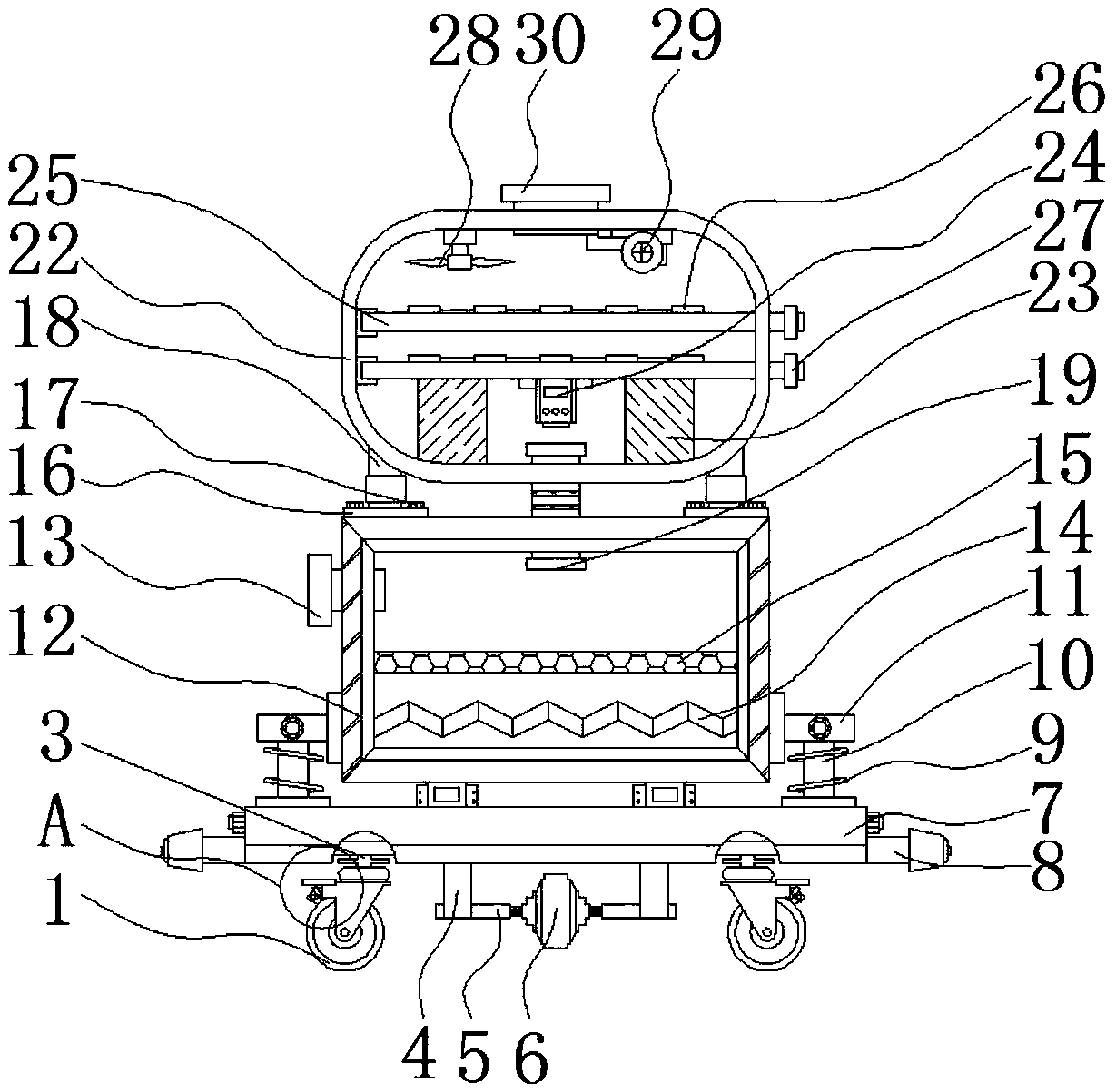

Thermocatalytic treatment volatile organic pollutant gas-collecting device with filtering function

InactiveCN109513715AEasy to fixEasy to carryDispersed particle separationDirt cleaningHazardous substanceActivated carbon filtration

The invention discloses a thermocatalytic treatment volatile organic pollutant gas-collecting device with a filtering function and relates to the technical field of powder packaging. The device comprises rollers and a stabilizing block. Brake pads are mounted on the upper portions of the rollers correspondingly, connecting blocks are arranged above the corresponding brake pads, and supporting plates are mounted at the right sides of the corresponding connecting blocks. The thermocatalytic treatment volatile organic pollutant gas-collecting device with the filtering function is provided with aheating box, a gas injecting port, a heating block, a permeating net, ejection rods, a conveying port and an activated carbon filter net, then a catalytic box at the top is well supported through theejection rods, a user can connect and fix a waste gas exhaust outlet and the gas injecting port well, waste gas is injected into the heating box, the heating block is started when the user uses the device, the heating block can be used for raising the temperature inside the heating box, temperature transmission is achieved through the permeating net, the temperature of the waste gas can be raised,the internal activated carbon filter net can be used for well filtering harmful substances in the waste gas, and finally, the waste gas is conveyed into the catalytic box.

Owner:FOSHAN UNIVERSITY

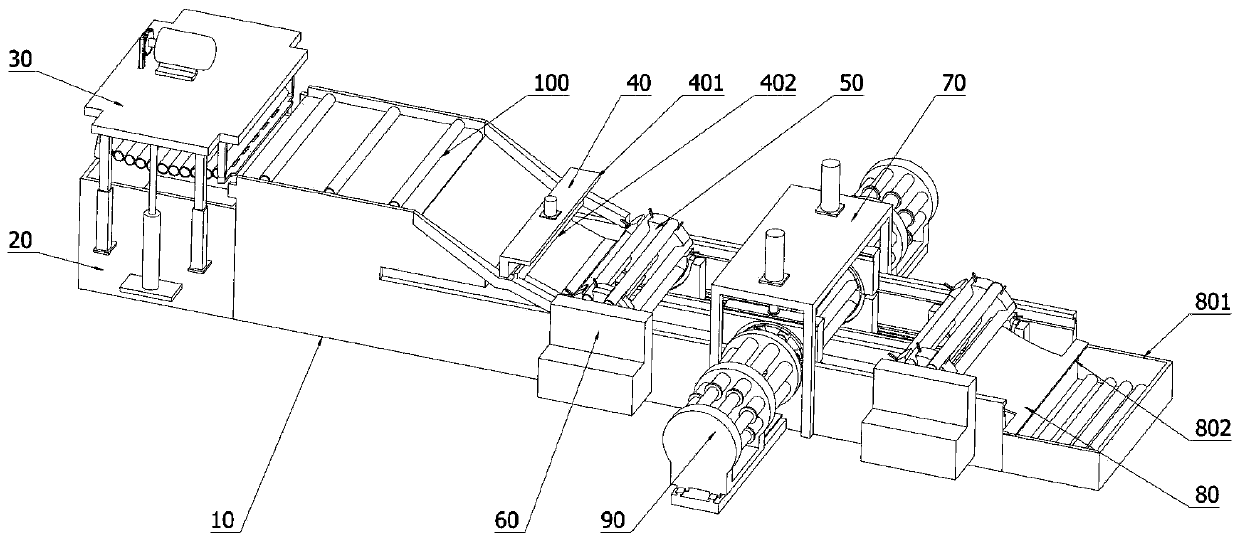

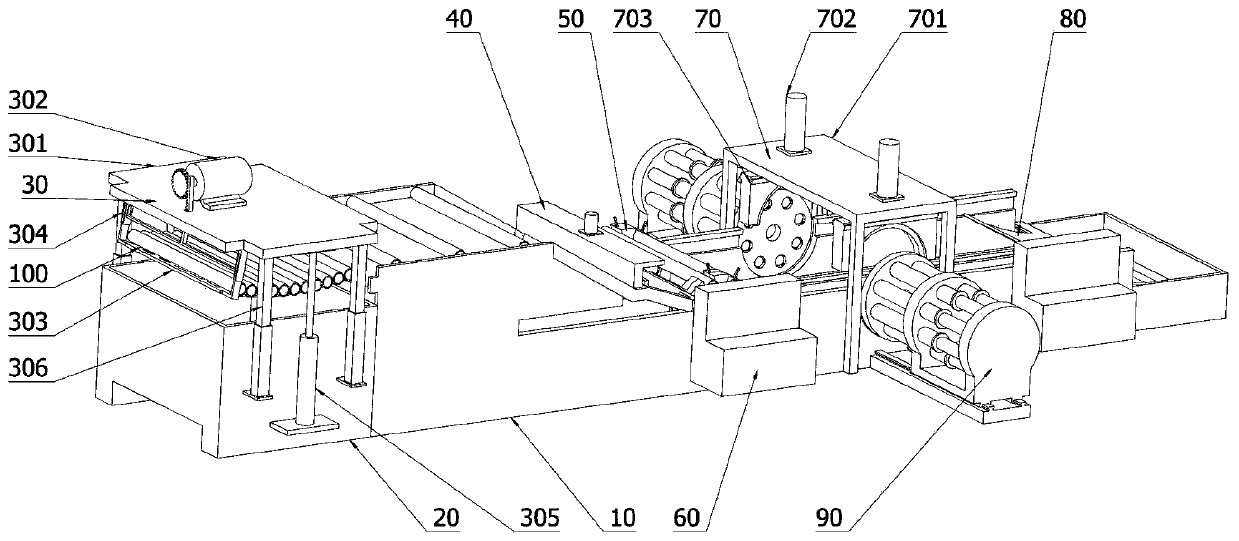

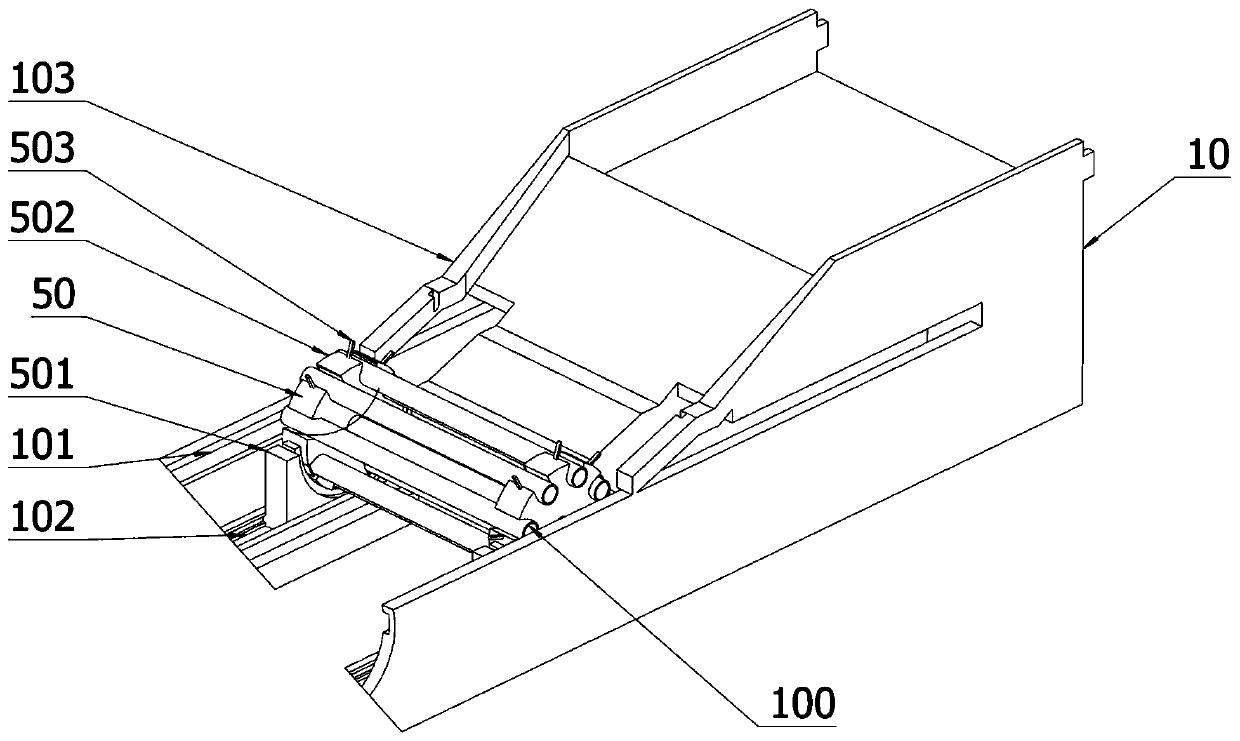

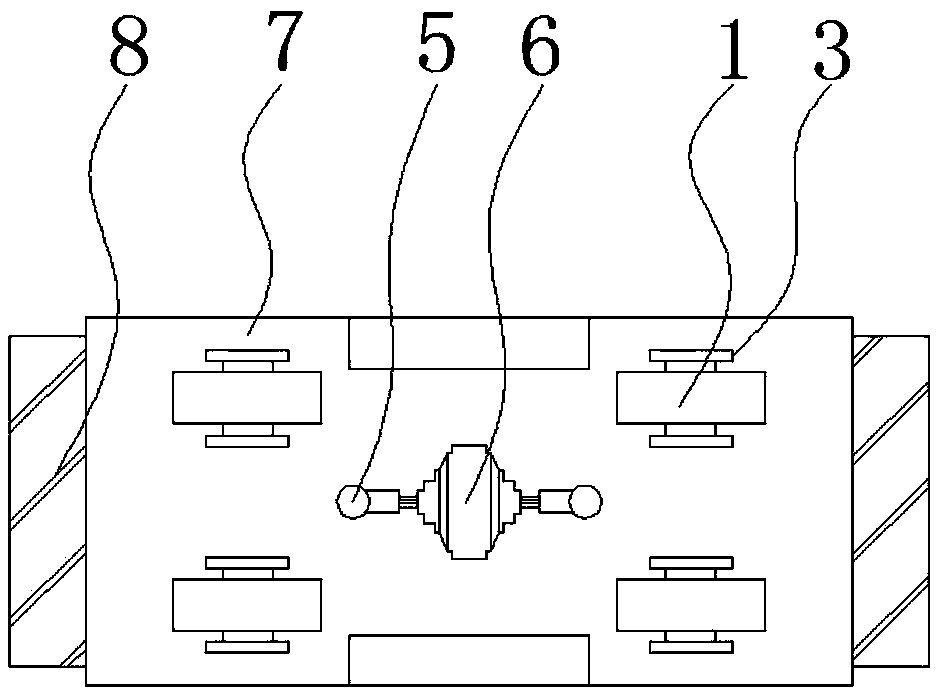

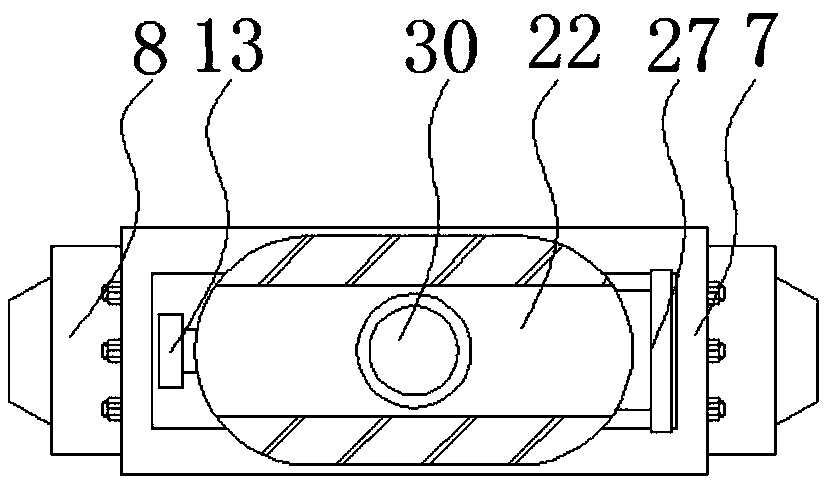

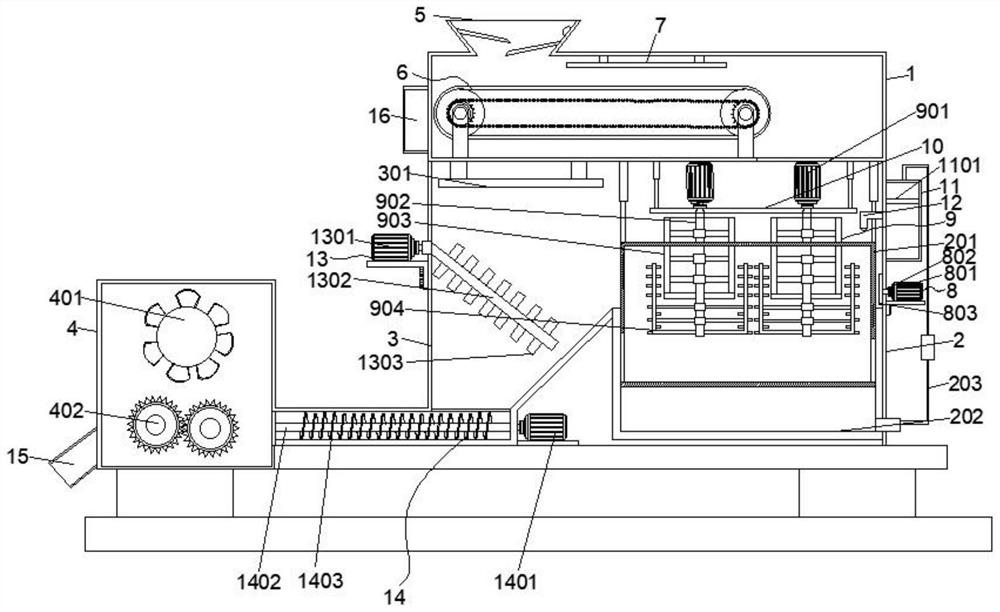

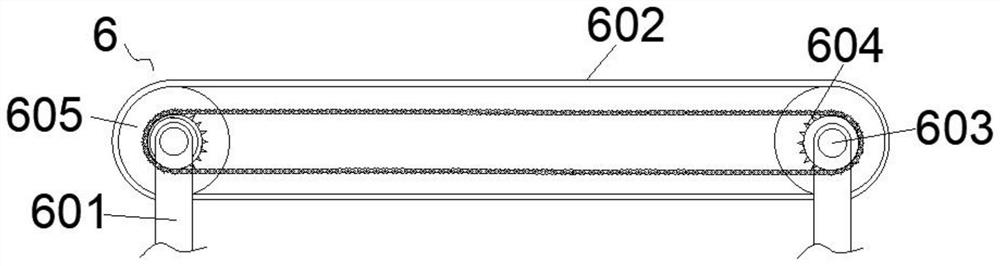

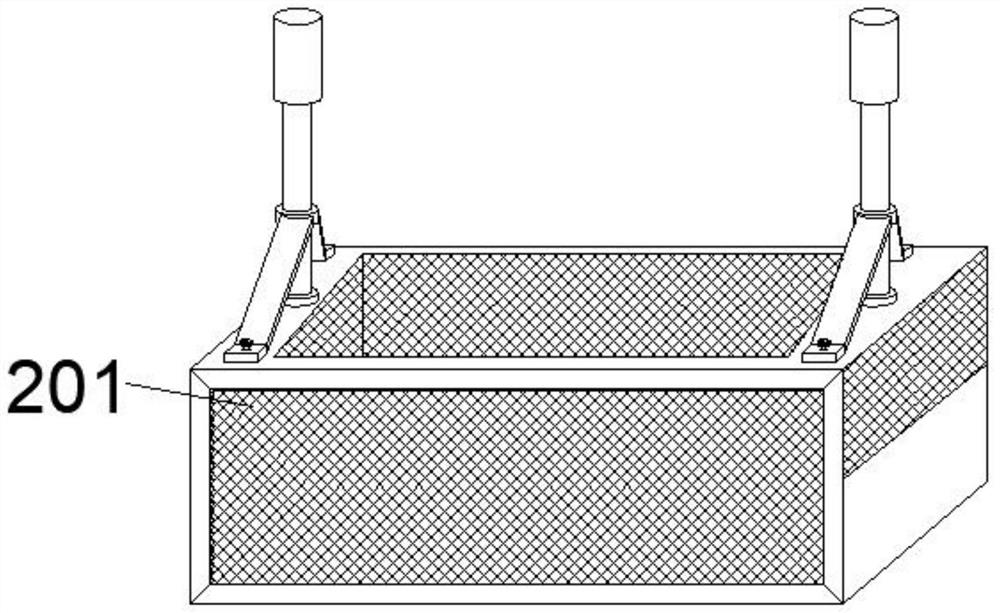

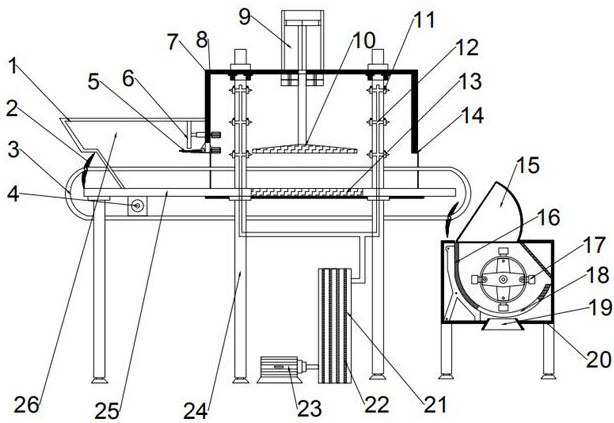

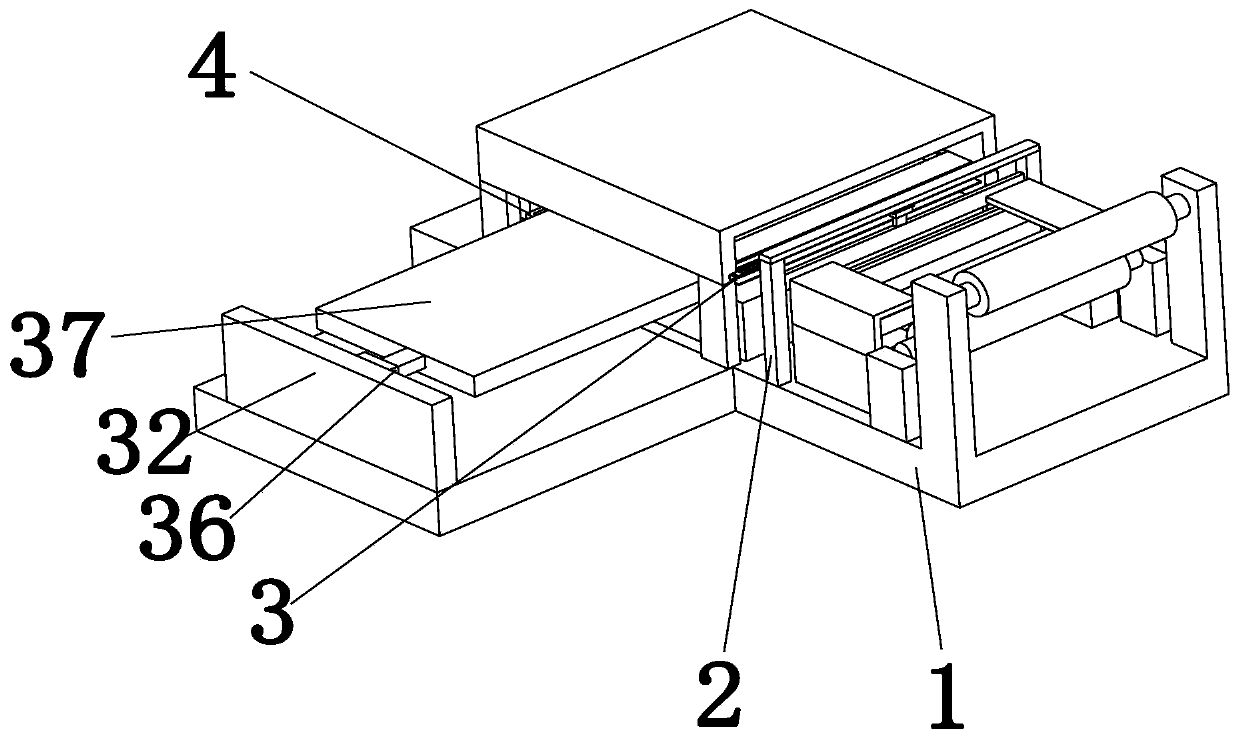

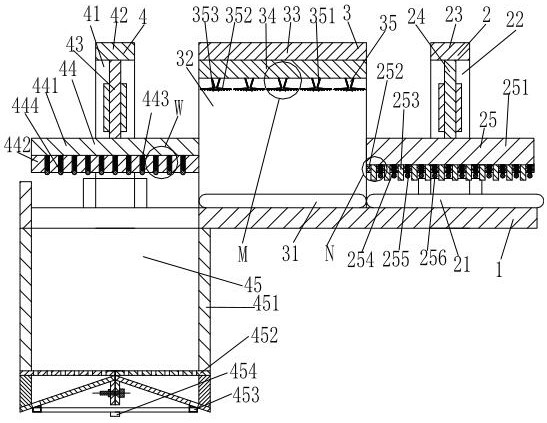

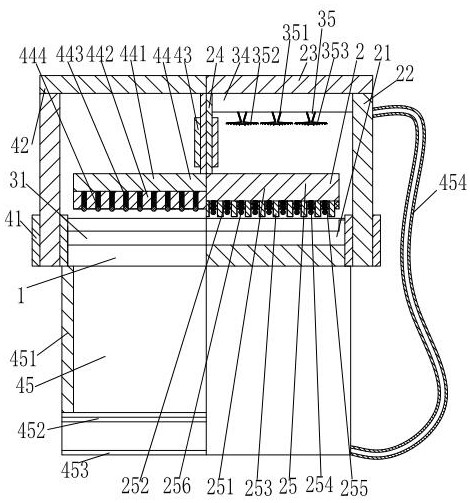

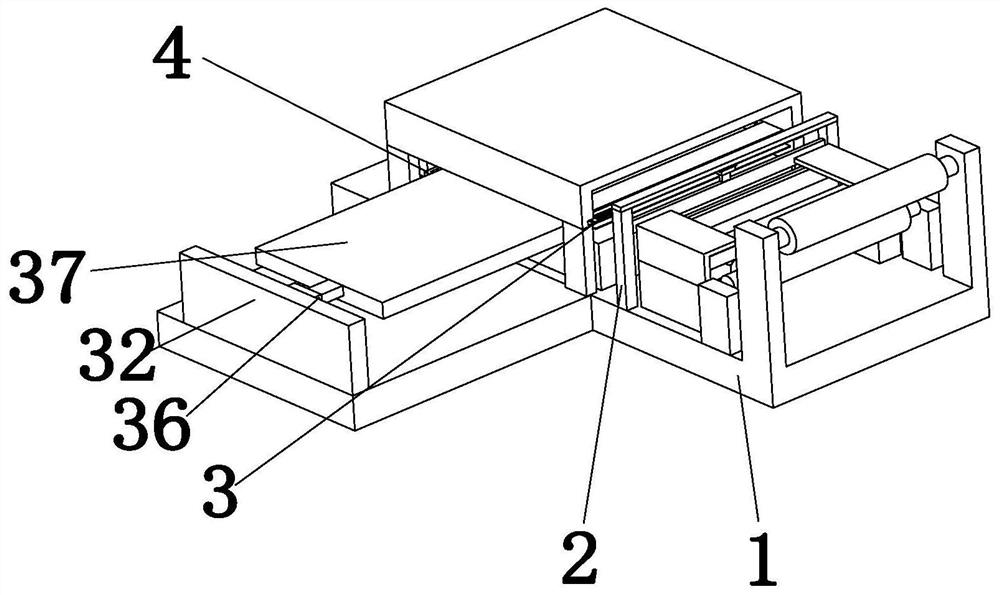

Integrated processing system for recycling packaging cartons

ActiveCN110695051AComplete humidity controlExpand the spraying areaSolid waste disposalLiquid spraying apparatusCarton flowCarton

The invention relates to an integrated processing system for recycling packaging cartons. The integrated processing system comprises a workbench, a flattening device, a humidifying device and a shaping device. The flattening device is mounted on the upper end face of the right side of the workbench. The humidifying device is mounted on the upper end face of the middle of the workbench. The shapingdevice is mounted at the left end of the humidifying device. A first telescopic support is adjusted to enable a first electric push rod to drive a rubber plate to squeeze a carton, and the surface ofthe carton is cut through a cross tool, so that complete humidification is facilitated; a metal spring is squeezed to generate opposite acting force to drive a rubber ball to squeeze the carton to beseparated from a pressing plate to enter the humidifying device, so that the situation that the carton is clamped on the rubber plate and the cross tool, and consequentially, the flattening process is affected is solved; and the carton is completely humidified through a water-spraying main frame and a flower-type spray head, and redundant water in the carton flows through a base plate and is finally delivered into the water-spraying main frame through a water delivery pipe, so that water is recycled.

Owner:泰州市合兴纸业有限公司

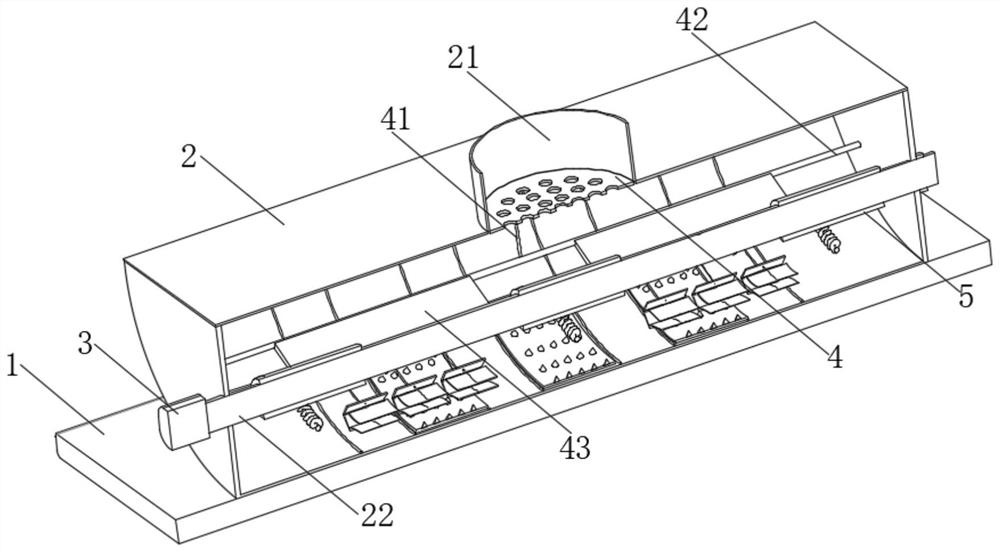

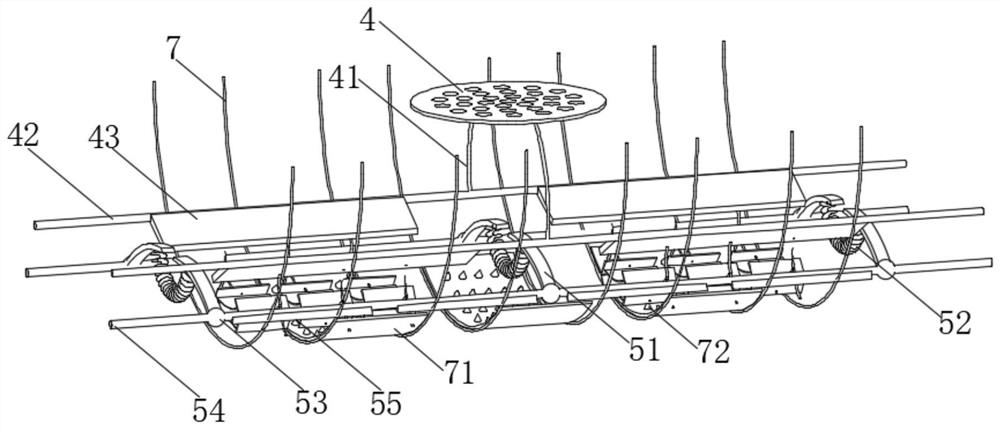

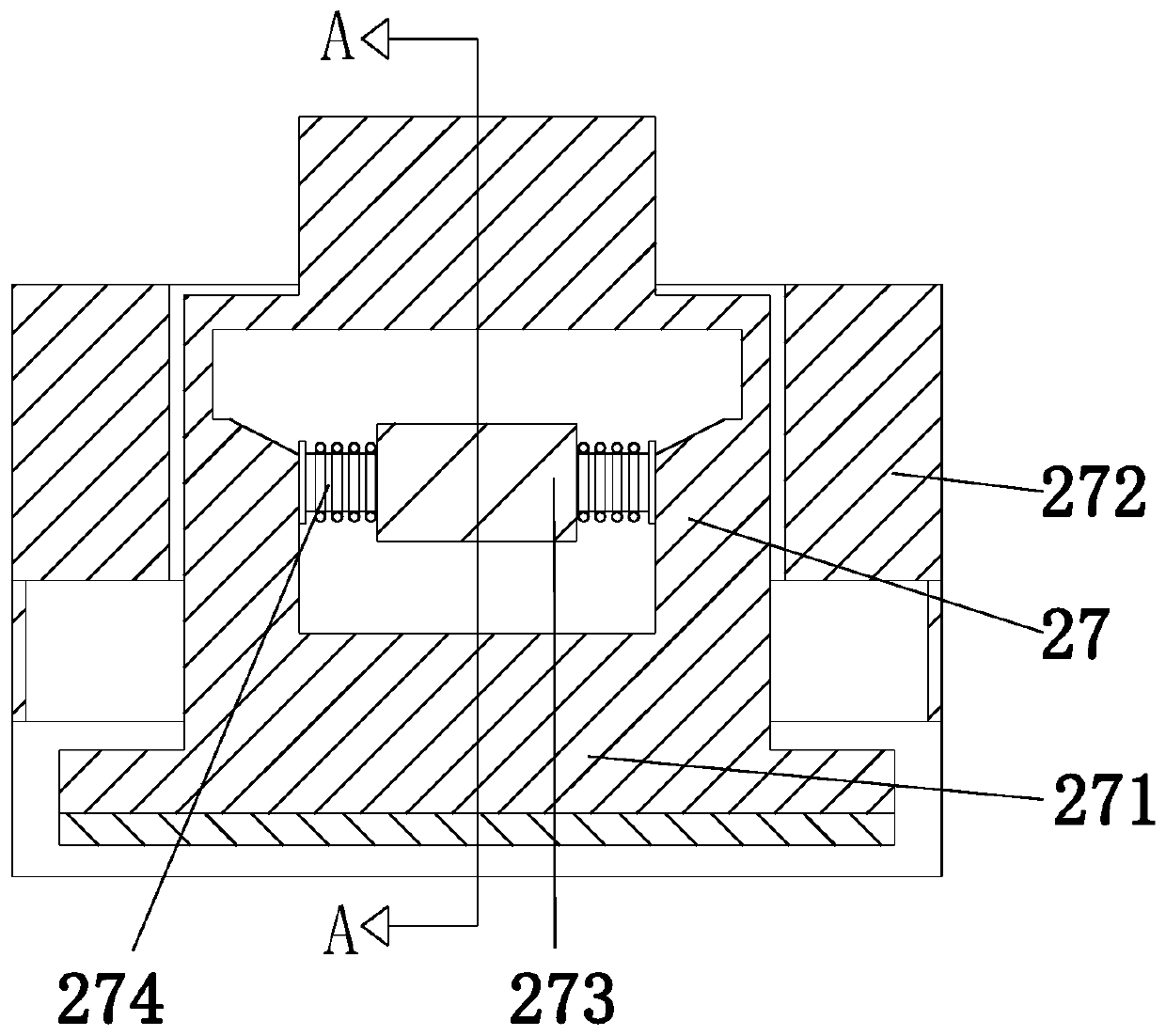

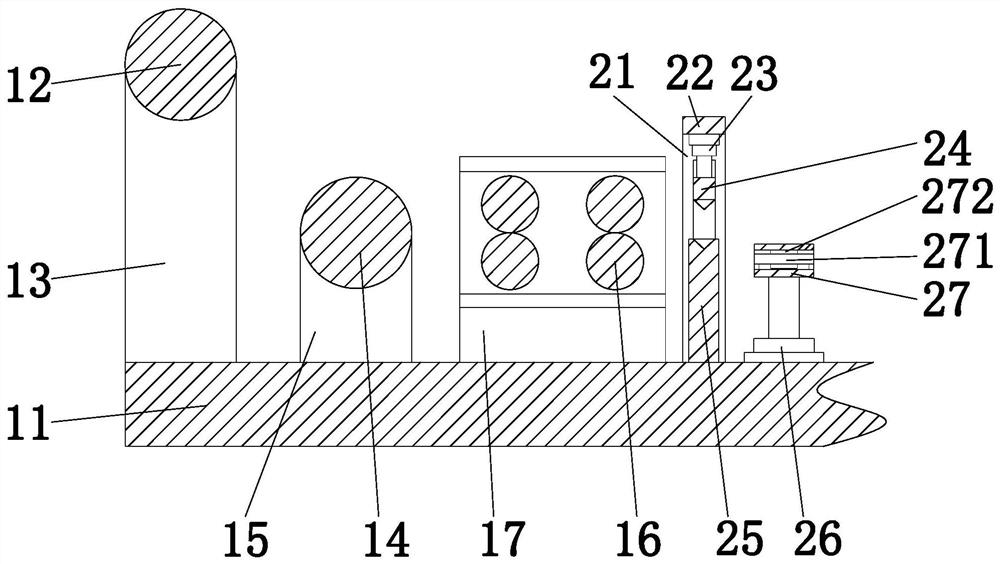

Rice flour integrated processing equipment

InactiveCN112958184AEffective disinfectionAct as a fixed supportGrain huskingGrain polishingAgricultural engineeringProcess engineering

The invention relates to the technical field of rice flour processing, and discloses rice flour integrated processing equipment, which comprises a conveying box, a cleaning box, a drying box and a smashing box. A conveying mechanism is arranged in the conveying box, and a lifting cylinder, a fixing cylinder and a stirring mechanism are arranged in the cleaning box. A pushing structure and a water tank are fixedly installed on the outer wall of the cleaning box, the stirring mechanism comprises a stirring motor, a stirring shaft, a first stirring support and a second stirring support, a water spraying part is fixedly installed in the cleaning box, a rotating mechanism is fixedly installed on one side of the drying box, and an opening is formed in the bottom of the drying box. A first smashing mechanism is arranged below the opening, a rotating roller and two smashing shafts are arranged in the smashing box, and a control device is fixedly installed on one side of the conveying box. The rice flour integrated processing equipment is novel in structure, capable of effectively improving the rice flour processing efficiency and reducing manual operation, beneficial to use by people and suitable for wide popularization.

Owner:安徽省东全米业股份有限公司

Sludge drying comprehensive treatment system

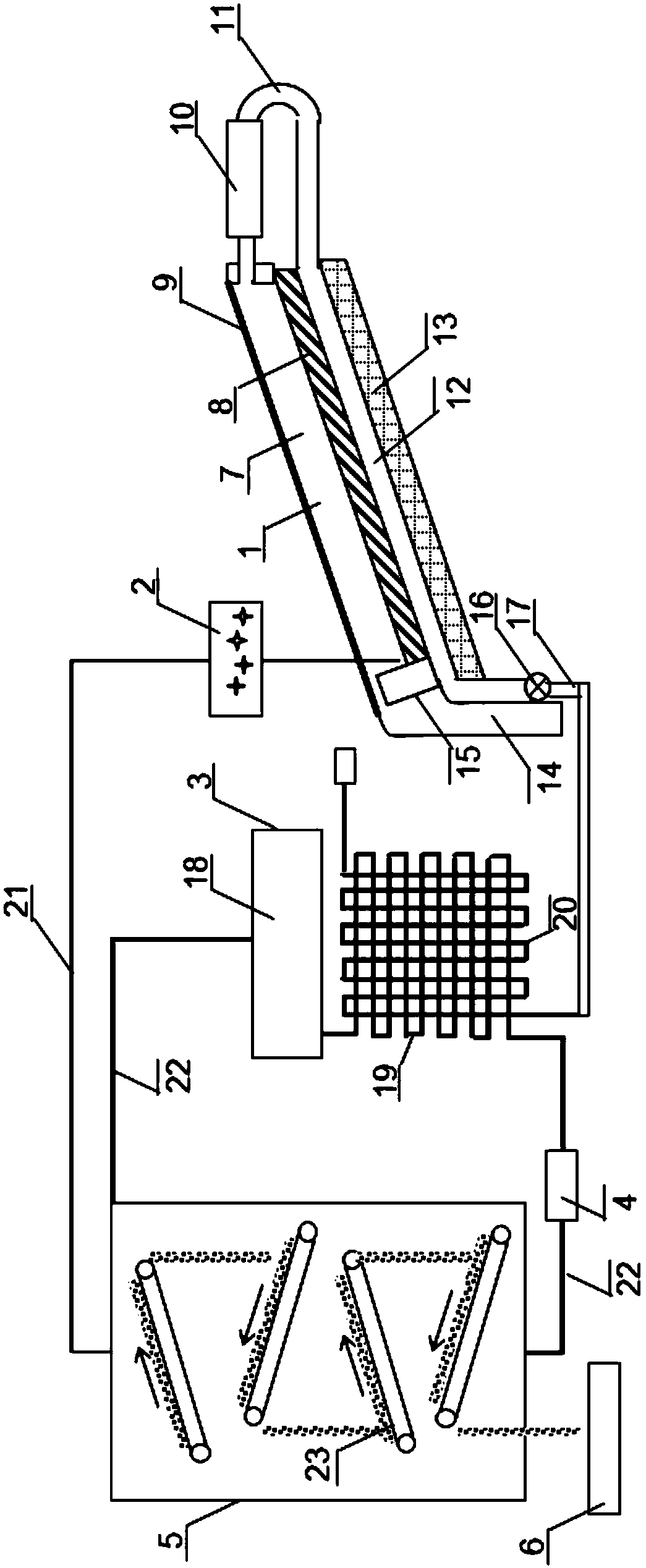

InactiveCN108238708AImprove efficiencyLow costSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTreatment costsIntegrated processing

The invention discloses a sludge drying comprehensive treatment system which comprises a solar high-temperature evaporation chamber, a sludge crusher, a condensation heat exchange system, a temperature control device, a sludge drying chamber and a sludge collection tank, wherein the solar high-temperature evaporation chamber, the condensation heat exchange system, the temperature control device and the sludge drying chamber are connected in turn; and the solar high-temperature evaporation chamber, the sludge crusher and the sludge drying chamber are connected, and the sludge collection tank isarranged at the bottom of the sludge drying chamber. The invention provides a sludge drying comprehensive treatment system which is used for dehydrating and drying sludge by use of solar energy, andhas the advantages of high sewage treatment efficiency and low sludge treatment cost; and the invention also discloses a method using the system.

Owner:南京城建环保水务股份有限公司

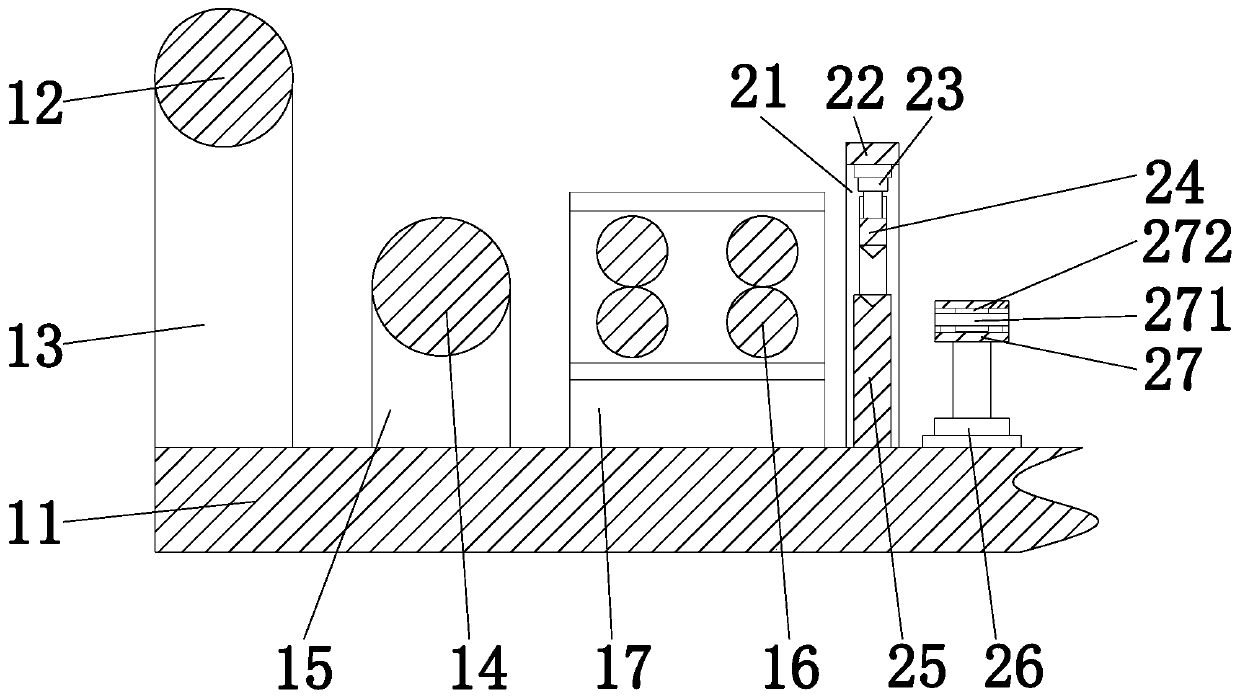

Wire pressing device for linear cutting machine tool

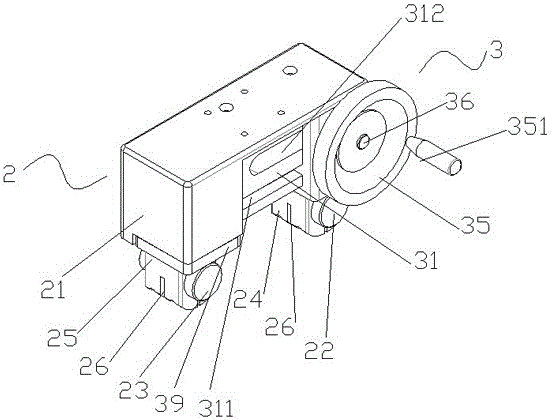

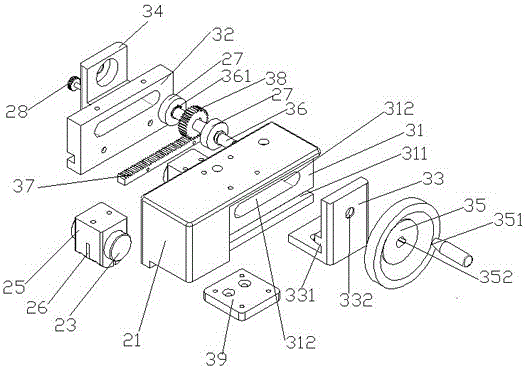

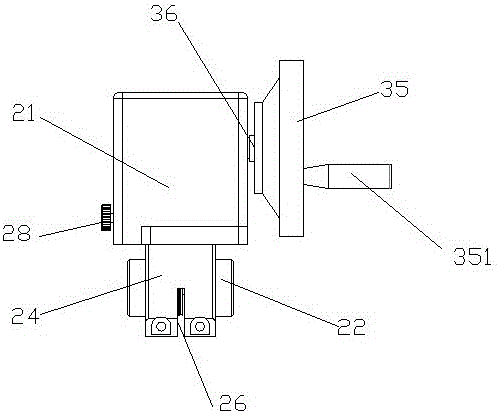

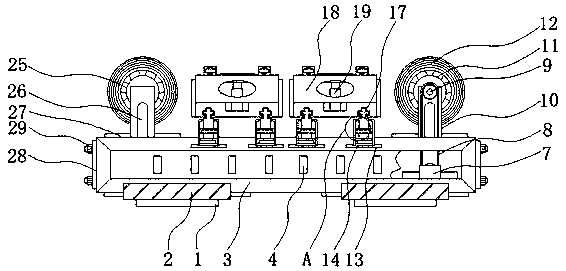

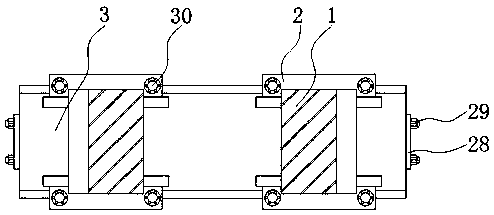

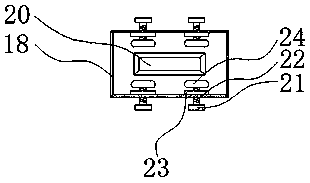

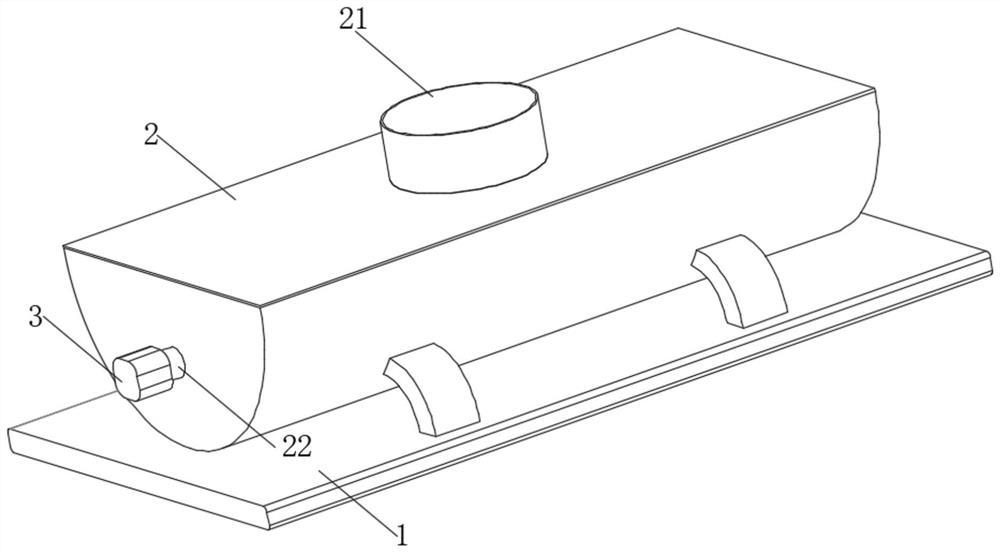

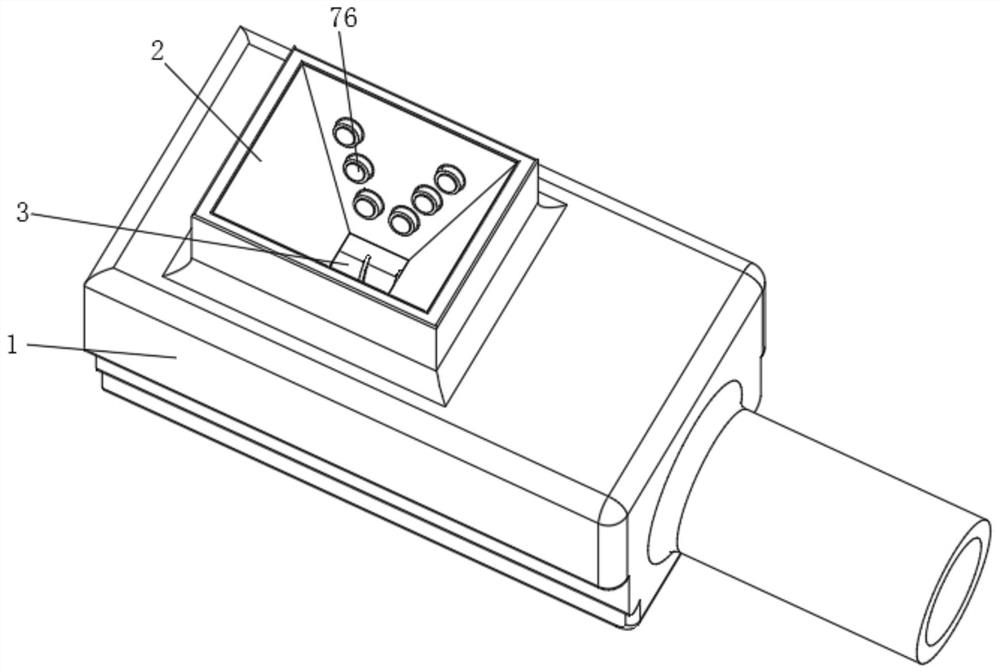

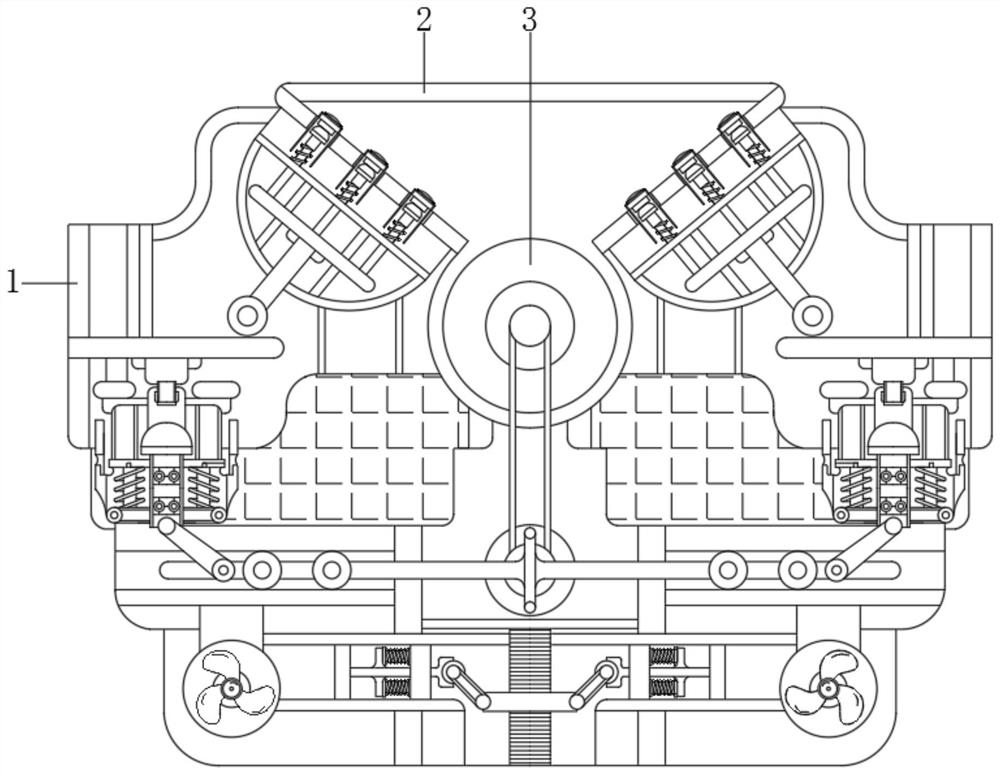

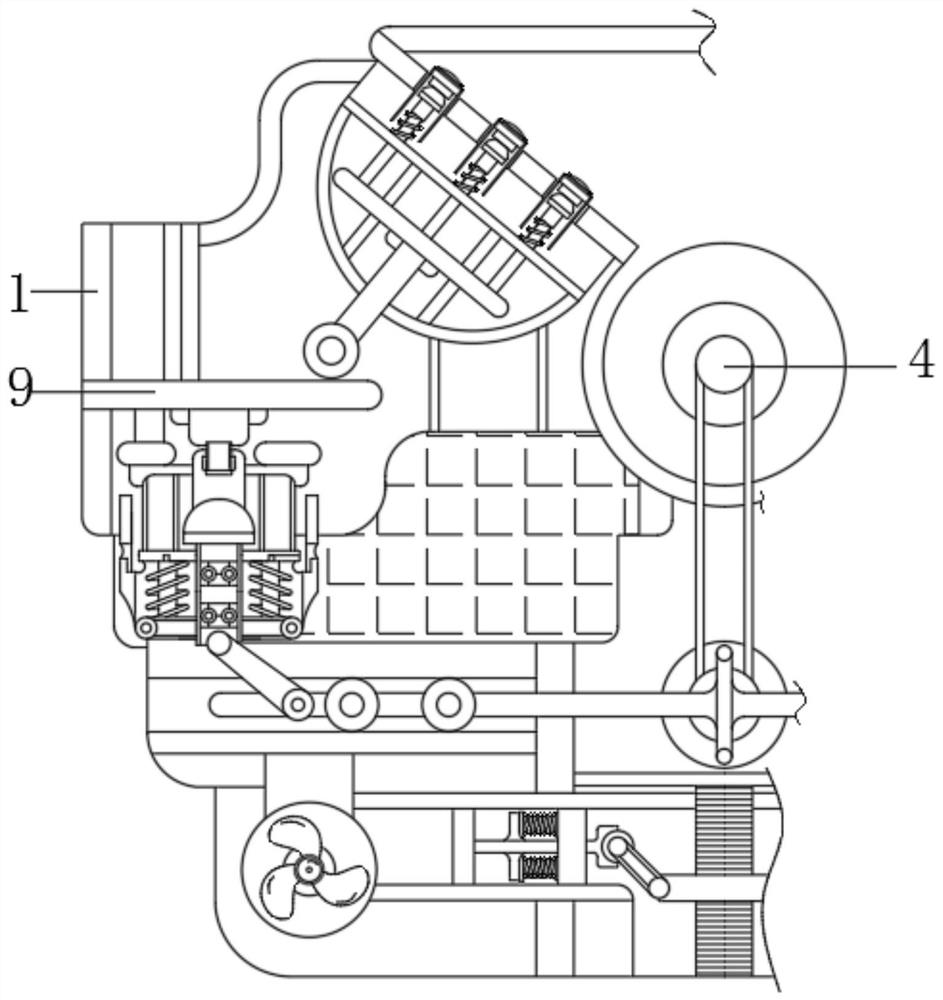

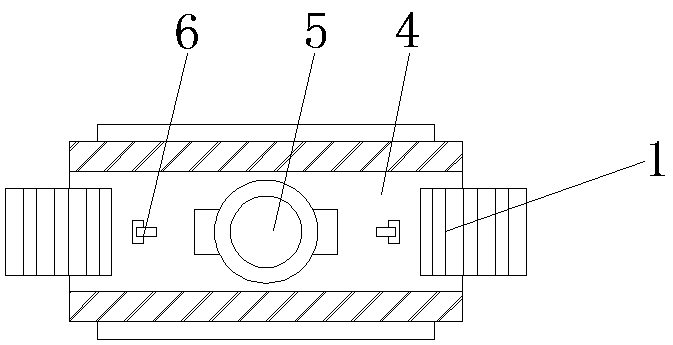

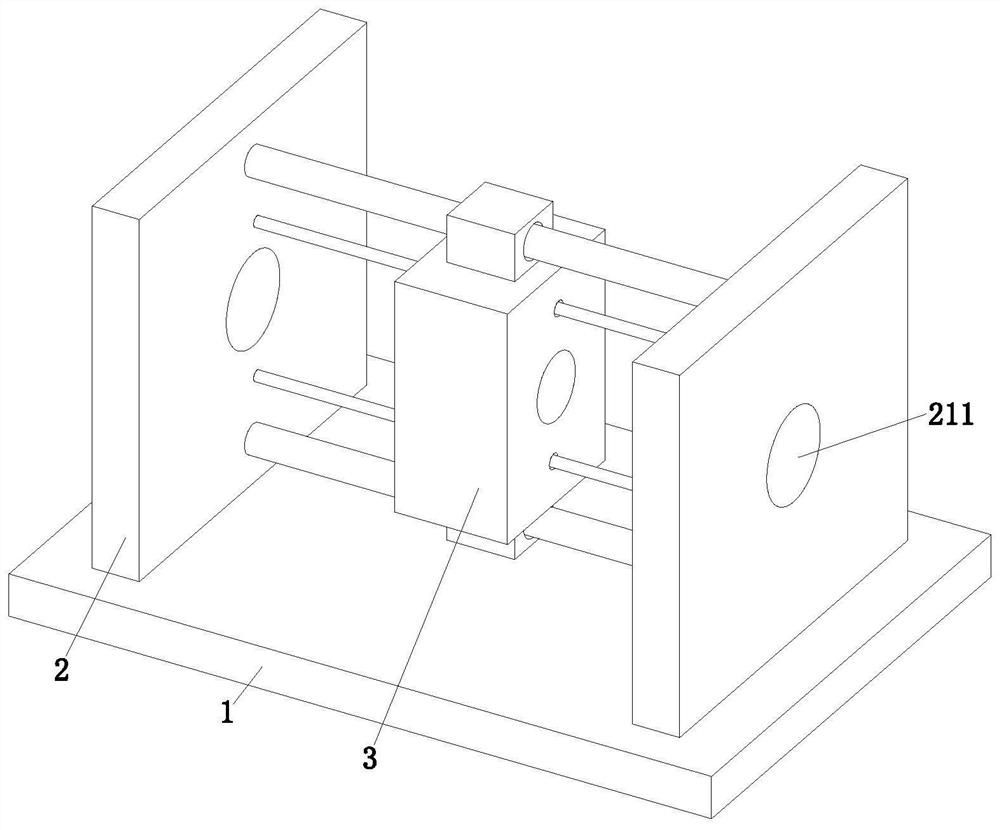

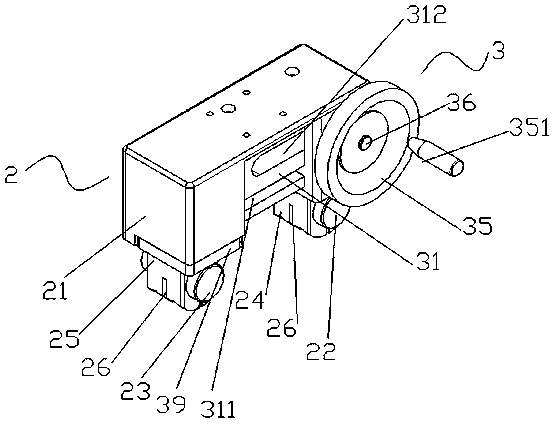

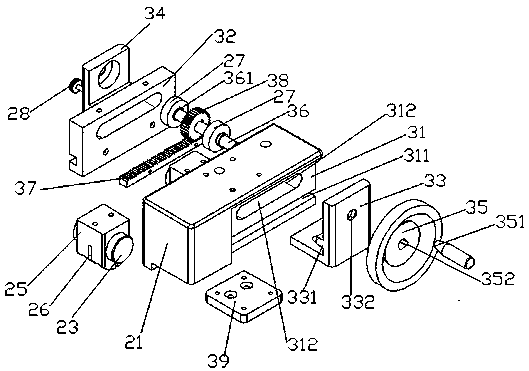

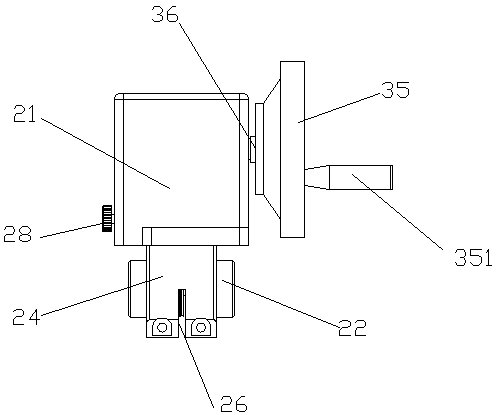

InactiveCN106270850AHigh strengthPrevent affecting processing efficiencyElectrical-based machining electrodesEngineeringMachining process

The invention discloses a wire pressing device for a linear cutting machine tool. The linear cutting machine tool is provided with the wire pressing device on the other side, opposite to a workpiece, of an electrode wire; the wire pressing device comprises a box body, and a slide mechanism connected to the box body; a first cutting guide wheel and a second cutting wheel are respectively arranged at two ends of the side surface, opposite to the electrode wire, of the box body; the first cutting guide wheel is connected with the slide mechanism through a first fixed block; the second cutting guide wheel is connected with the box body through a second fixed block; wire pressing grooves for accommodating the electrode wire are respectively formed in one surfaces, opposite to the electrode wire, of the first fixed block and the second fixed block; and the two wire pressing grooves are respectively communicated with the first cutting guide wheel and the second cutting guide wheel. The wire pressing device can adjust the length of the electrode wire on a machining section, and horizontally moves to contact the electrode wire with the workpiece for machining, so that the electrode wire on the machining section is stable in strength, the deformation of the workpiece caused by looseness of the electrode wire in the machining process is prevented, and the machining precision is guaranteed.

Owner:GUANGDONG UNIV OF TECH

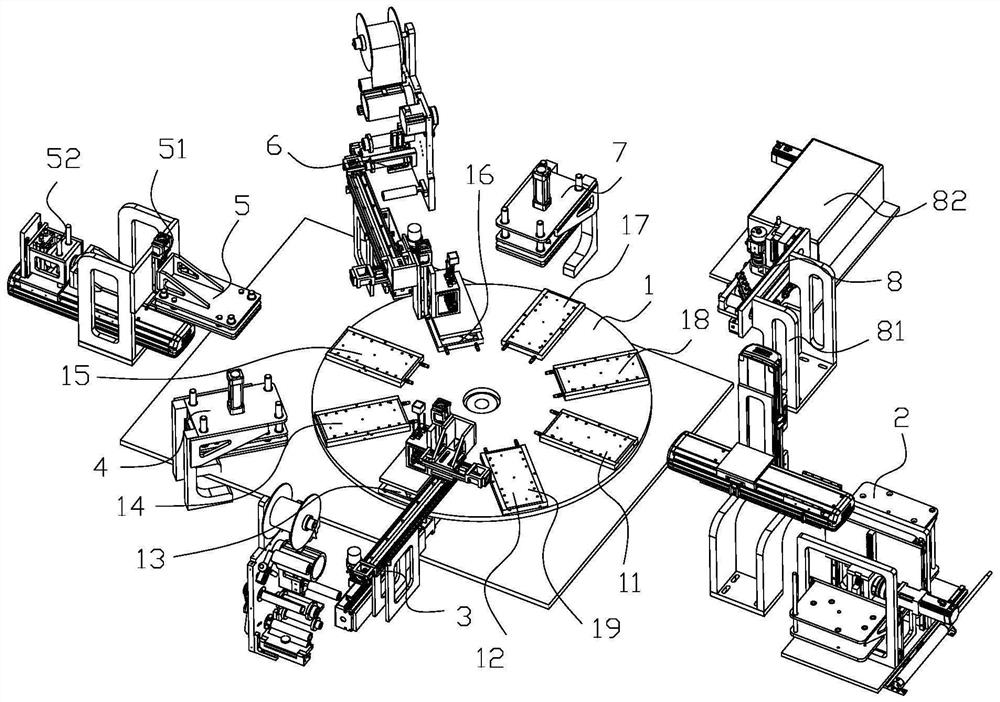

Sorting and welding integrated equipment for lithium battery processing

InactiveCN112246694AEasy to control the output speedPrevent affecting processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses sorting and welding integrated equipment for lithium battery processing. The sorting and welding integrated equipment comprises a first workbench, detection mechanisms and a vertical rod, wherein a feeding box is fixed to the left side of the first workbench, a first motor is fixed to the outer side of the feeding box, a rotating roller is rotatably connected to the interior of the feeding box, and fixing blocks are fixed to fixing frames; and the vertical rod is fixed to the right side of the first workbench, a rotating plate is rotatably connected to the outer side ofa movable block, third springs are fixed to the right sides of second baffles, and a clamping plate is fixed to each third spring. The sorting and welding integrated equipment for lithium battery processing is provided with the first motor, the rotating roller and empty grooves, the rotating roller in the feeding box is driven by the first motor to rotate, lithium batteries sequentially fall intothe empty grooves in the surface of the rotating roller, and the lithium batteries fall onto an external first conveying belt from a discharging opening in the bottom of the feeding box in cooperation with rotation of the rotating roller, so that the discharging speed of the lithium batteries is conveniently controlled, and the processing efficiency is prevented from being influenced by blockage.

Owner:江苏英能新能源科技有限公司

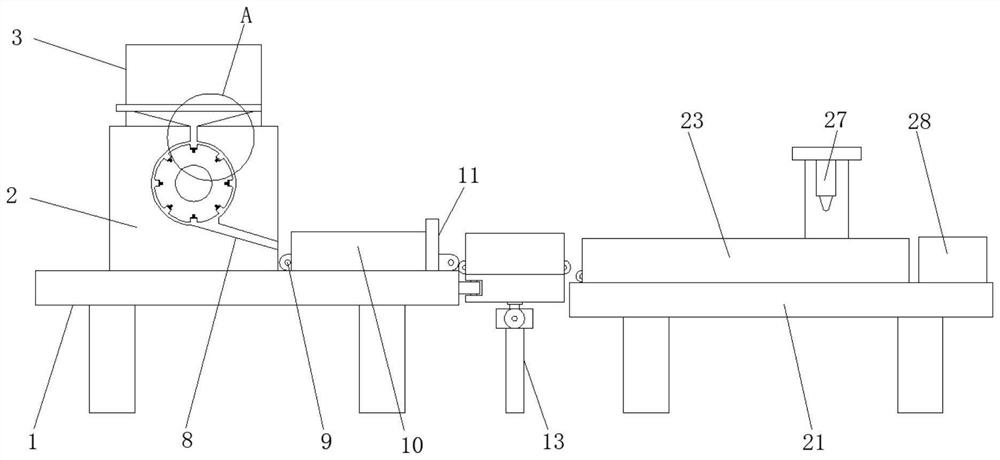

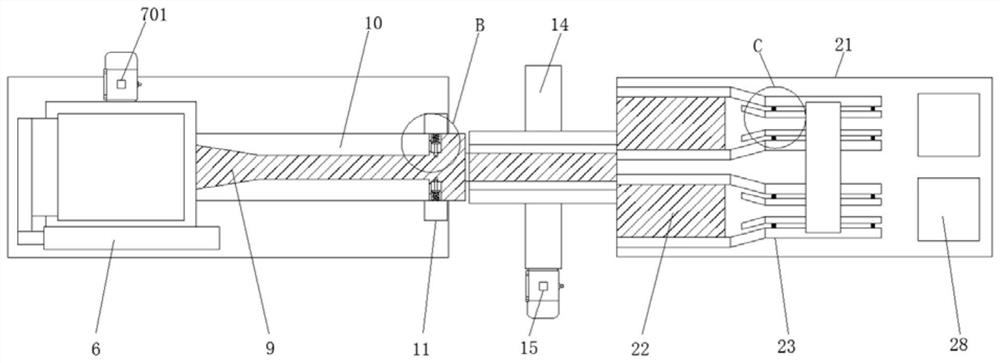

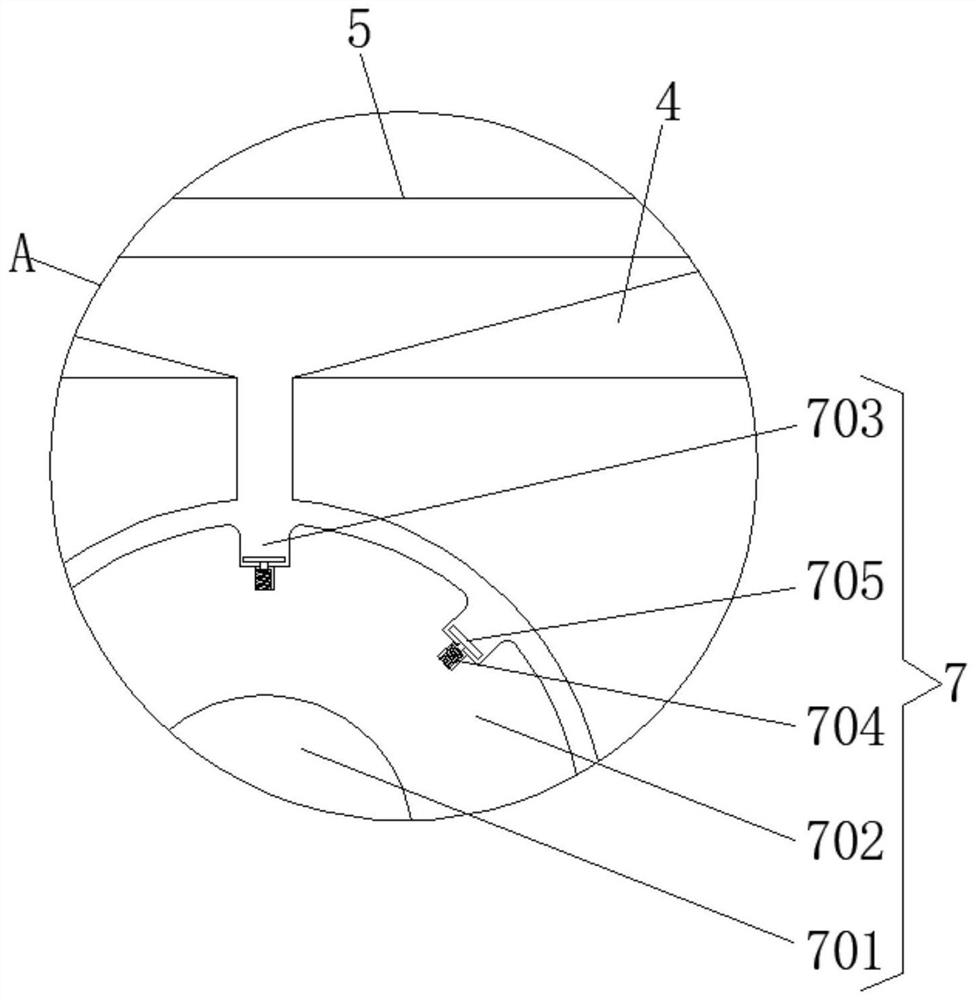

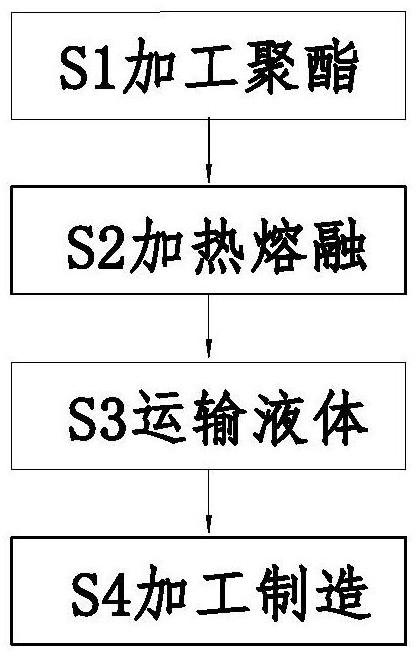

Manufacturing process of spun-bonded non-woven fabric

ActiveCN112458549AImprove efficiencyAffect UtilizationSpinning solution de-aeratingFilament forming substance formingPolyesterProcess engineering

The invention relates to a manufacturing process of spun-bonded non-woven fabric. A device implementing the manufacturing process comprises a workbench, a conveying device and a processing device, wherein the conveying device is fixedly installed at the upper end of the workbench, the processing device is fixedly installed at the upper end of the left side of the conveying device, and the conveying device comprises a heat preservation barrel, a heating plate, a glass plate, a first motor, a screw rod, a filtering plate, a conveying pipe and a heat preservation pipe. Polyester slices are heatedthrough the conveying device and are completely in a molten state, so that processing quality is prevented from being affected, meanwhile, liquid polyester attached to the inner wall of a part is scraped to prevent a utilization rate of the polyester from being affected, and polyester raw materials are sliced through the processing device and screened, so that the polyester slices which do not meet the standard are prevented from entering the conveying device and thus prevented from affecting the processing efficiency, meanwhile, the particle size of the polyester slices can be limited as required, and thus the use efficiency of equipment is improved.

Owner:佛山市顺德区宝富莱无纺布有限公司

Wood board anti-corrosion spraying device

InactiveCN112718349AImproved anti-corrosion processingHarm reductionPretreated surfacesCoatingsPulp and paper industryMechanical engineering

The invention provides a wood board anti-corrosion spraying device which comprises a base, a fixing unit and a spraying unit. A circular sliding groove is formed in the upper end of the base, the fixing unit is arranged in the circular sliding groove in a sliding manner, and the spraying unit is installed on the fixing unit. The wood board anti-corrosion spraying device can solve the problems that in traditional wood board anti-corrosion treatment, most wood boards are manually sprayed with a corrosion remover, due to the fact that corrosion remover components are complex, great harm is easily caused to human bodies, the uniformity of the corrosion remover cannot be guaranteed through manual operation, secondary repairing needs to be conducted, the workload is increased, and the sprayed wood boards need to be naturally air-dried, so that dust is easily attached to the surfaces of the wood boards, and the anti-corrosion effect of the wood boards is affected.

Owner:安徽亿霖木业有限公司

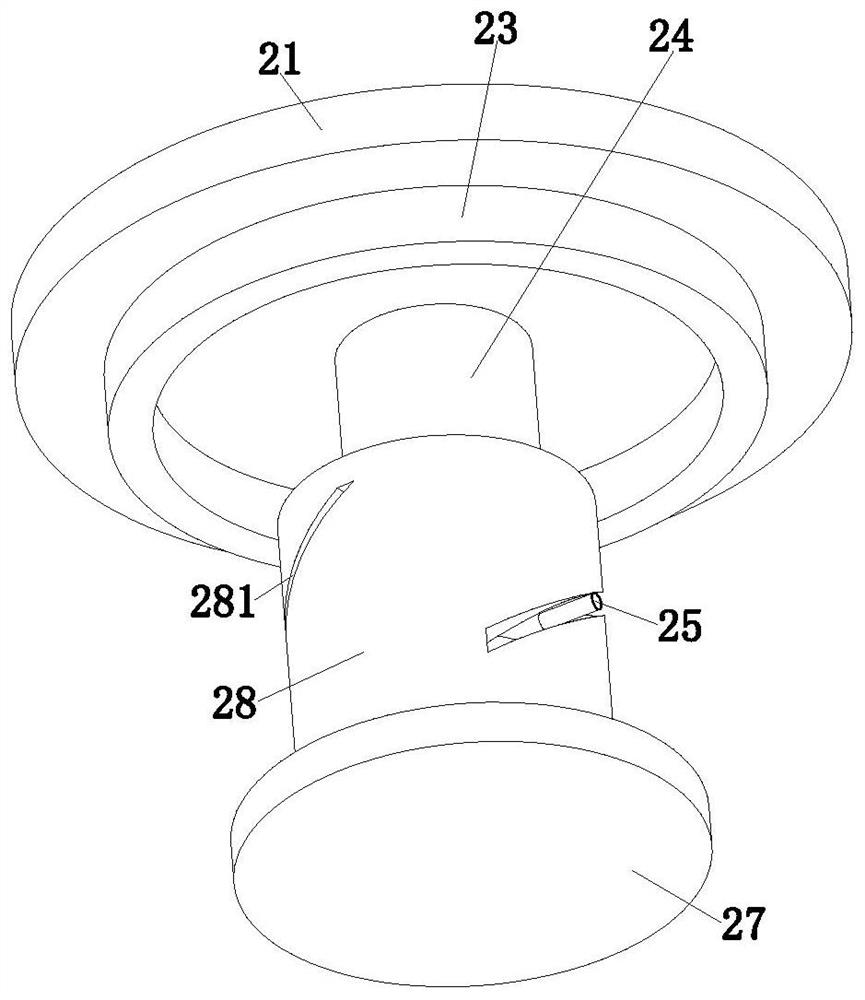

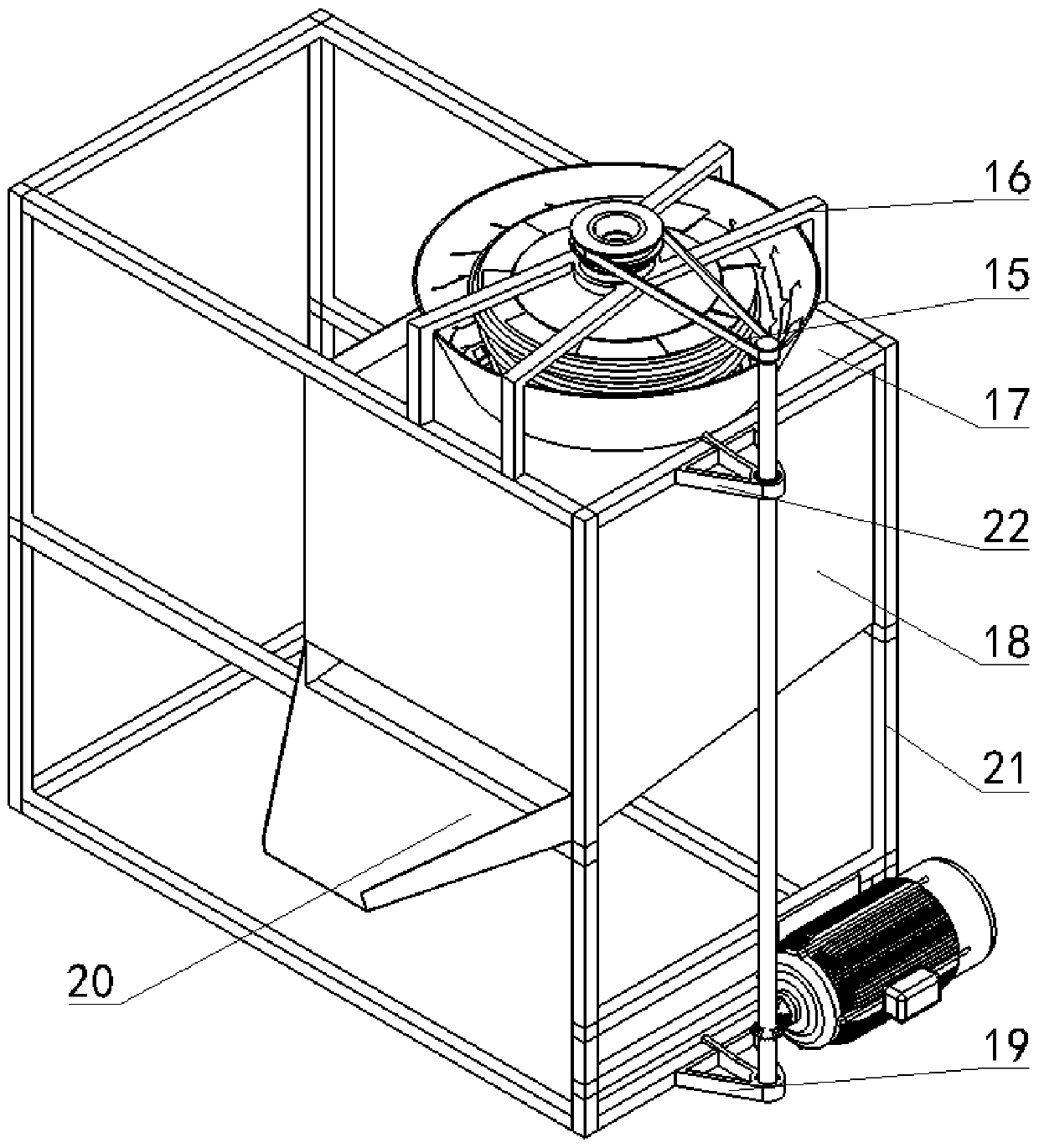

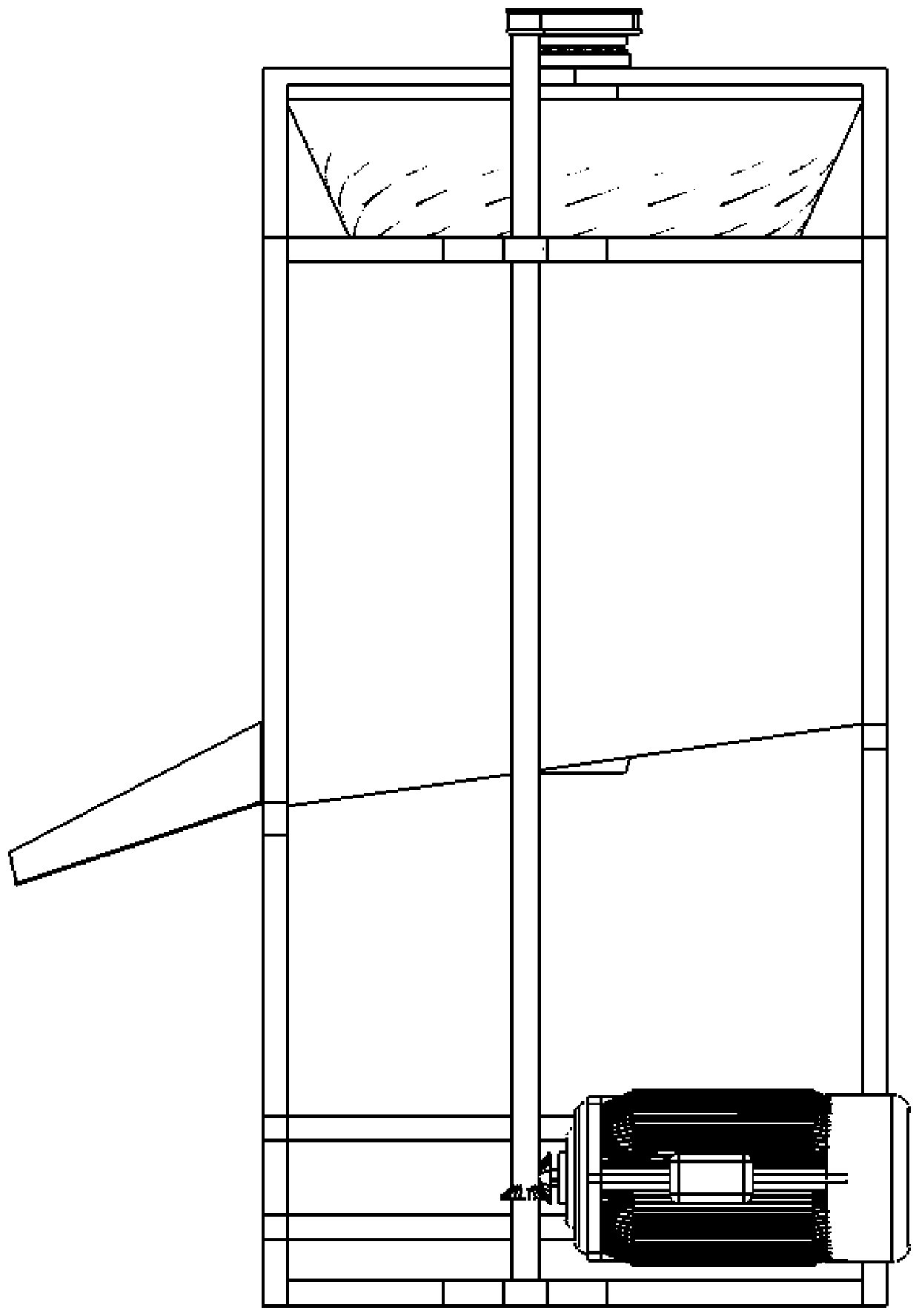

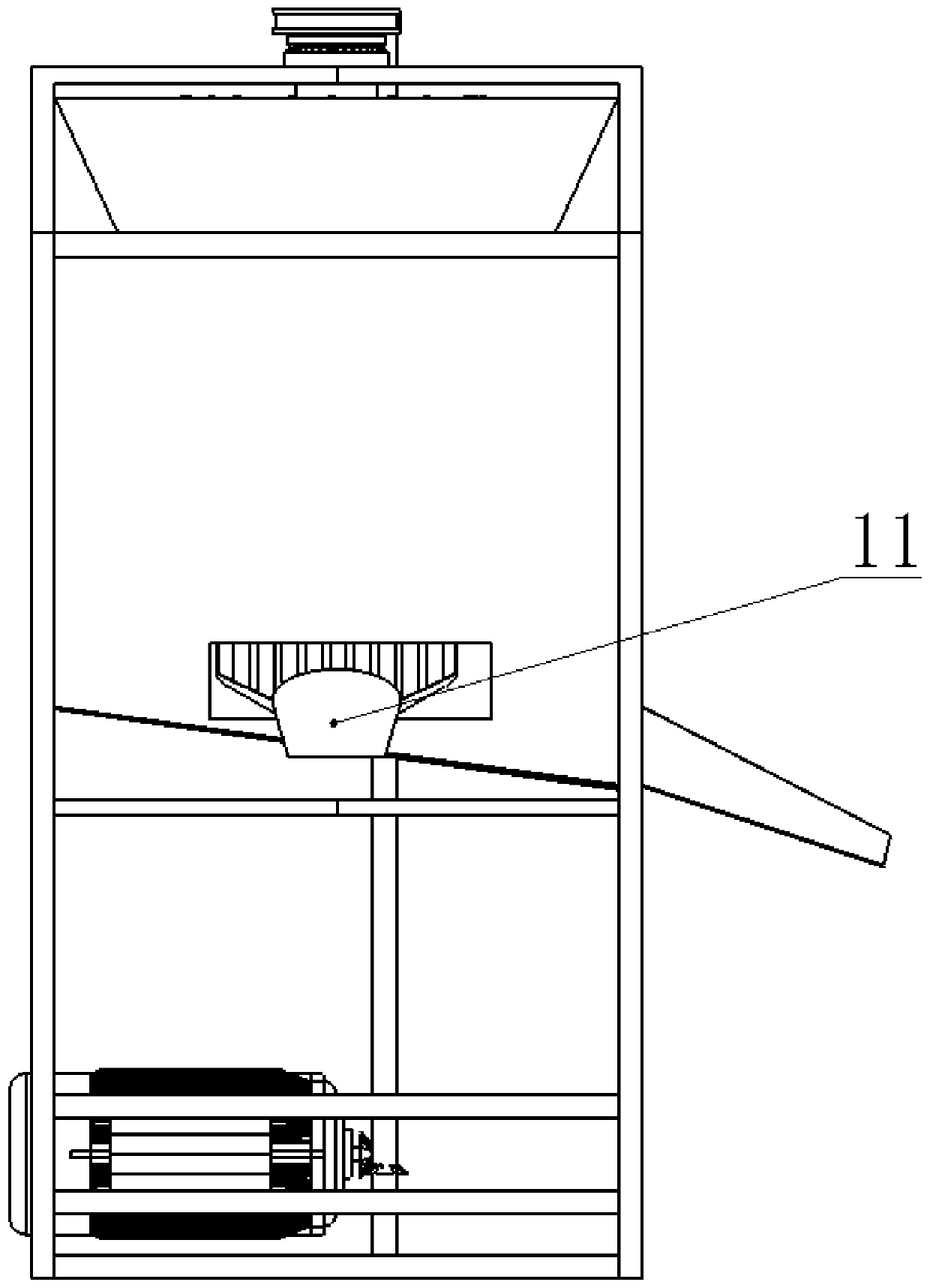

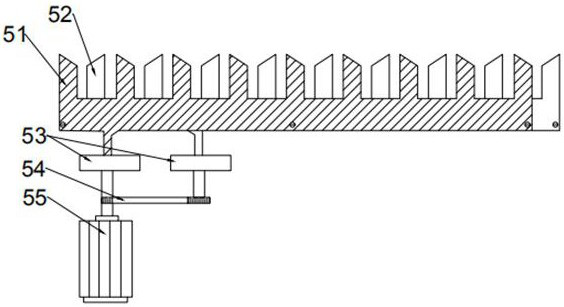

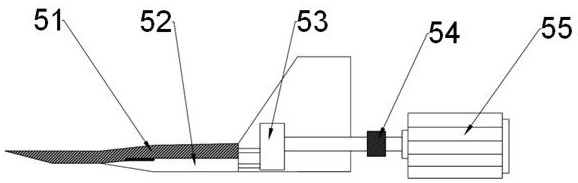

Vertical conical spiral laminated knife green seedcase removing device

InactiveCN111557454ASmall footprintImprove processing efficiencyHuskingHullingStructural engineeringKnife blades

The invention discloses a vertical conical spiral laminated knife green seedcase removing device which comprises a conical funnel, a conical spiral laminated knife, a separation grid plate with a funnel, a fixed supporting mechanism and a power mechanism. The conical funnel and the conical spiral laminated knife are mounted on the fixed supporting mechanism; the conical funnel comprises an upper part and a lower part which are different in taper; a plurality of green seedcase outlets are formed in the side wall of the upper part of the conical funnel; a plurality of cutting blades are arrangedon the inner wall of the upper part of the conical funnel; a wire brush is arranged on the inner wall of the lower part of the conical funnel; the conical spiral laminated knife is positioned in theconical funnel, and is driven by the power mechanism to rotate in the conical funnel; and the separation grid plate with a funnel is arranged below the conical funnel.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

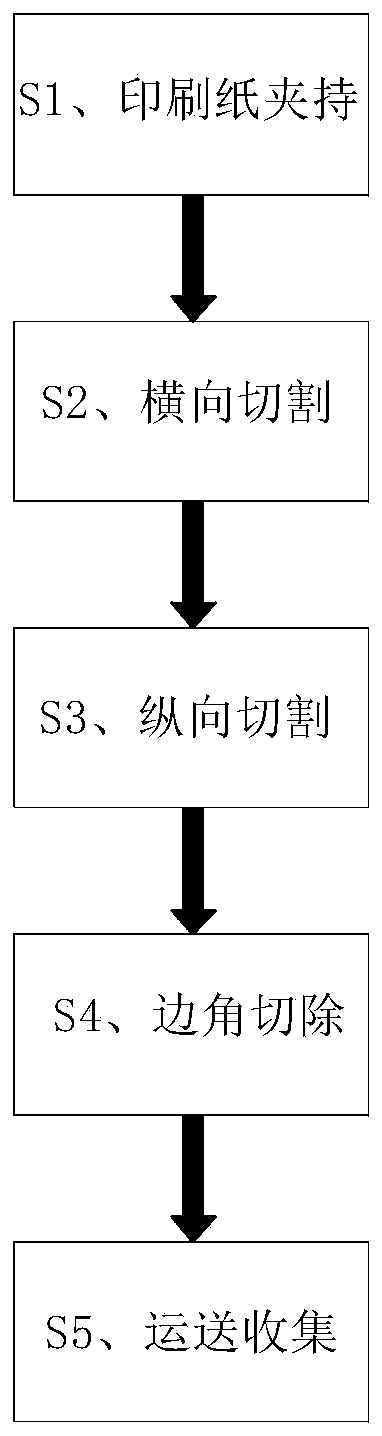

Processing technology for printing paper

ActiveCN111516037AAchieve horizontal cuttingAvoid the problem of frequent tool changesMetal working apparatusProcess engineeringManufacturing engineering

Owner:东莞市新锐源防伪科技有限公司

Pretreatment equipment for high-water-content clayed soil

InactiveCN111872082AIncrease the heating areaReduce drying energy consumptionDispersed particle separationContaminated soil reclamationEngineeringHigh water content

The invention relates to pretreatment equipment for high-water-content cohesive soil, which comprises a bottom supporting steel plate, and a feeding device and a drying device which are communicated with each other are arranged on the bottom supporting steel plate; the feeding bin comprises a feeding bin shell, wherein a feeding port is formed in the feeding bin shell, a feeding scraper power railis arranged in the feeding bin shell and driven by a feeding scraper power motor, and a feeding scraper is arranged at the end, close to the feeding port, of the feeding scraper power rail. A reciprocating type ruler-shaped soil cutter and a telescopic bulldozing plate are arranged at the front end of the portion, communicated with the drying device, of the feeding device, and the reciprocating type ruler-shaped soil cutter is located below the telescopic bulldozing plate. According to the invention, the moisture in soil is squeezed out through the hydraulic system, so that the heating area is increased, polluted soil can be rapidly and thoroughly dried, and the problems that when existing equipment is used for treating high-moisture-content clayed soil, efficiency is low, and energy consumption is high are solved, and the treatment efficiency for the high-moisture-content clayed soil is greatly improved.

Owner:HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Grapefruit pulp taking device

InactiveCN112352971AAvoid wastingAffect recycling efficiencyVegetable peelingDrive motorIndustrial engineering

The invention provides a grapefruit pulp taking device, and relates to the technical field of fruit processing. The grapefruit pulp taking device comprises a shell, bases, a cutting mechanism, a pulptaking mechanism, a conveying device and a first driving motor, the bases are arranged below the left end and the right end of the shell, and the left end and the right end of the shell are fixedly connected with the bases. The cutting mechanism is arranged at the position, close to the left end, of the interior of the shell, the two ends of the grapefruit are cut through the cutting mechanism, and excessive grapefruit pulp is prevented from being cut when the two ends of the grapefruit are cut; the top end of the cutting mechanism is fixedly connected with the top end of the shell, the pulp taking mechanism is arranged on the right side of the middle part of the inside of the shell, the top of the pulp taking mechanism is fixedly connected to the top of the shell, and the conveying deviceis arranged below the cutting mechanism, a first driving motor is arranged on the right side of the left end of the conveying device, the output end of the first driving motor penetrates through thebase to be fixedly connected with the conveying device, and the problem that in the grapefruit processing process, the efficiency is low when grapefruits are peeled, pulped and taken manually is solved.

Owner:许其福

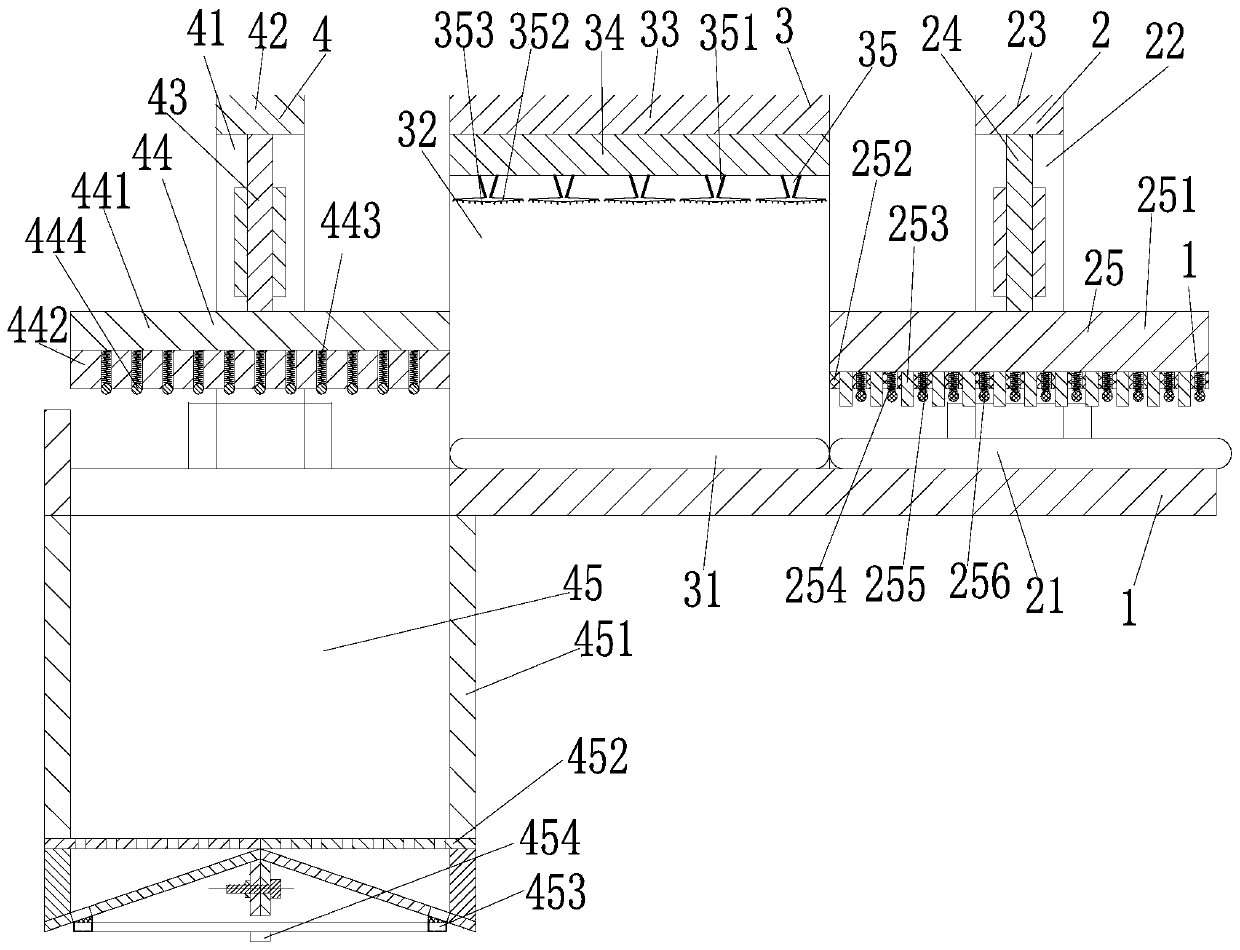

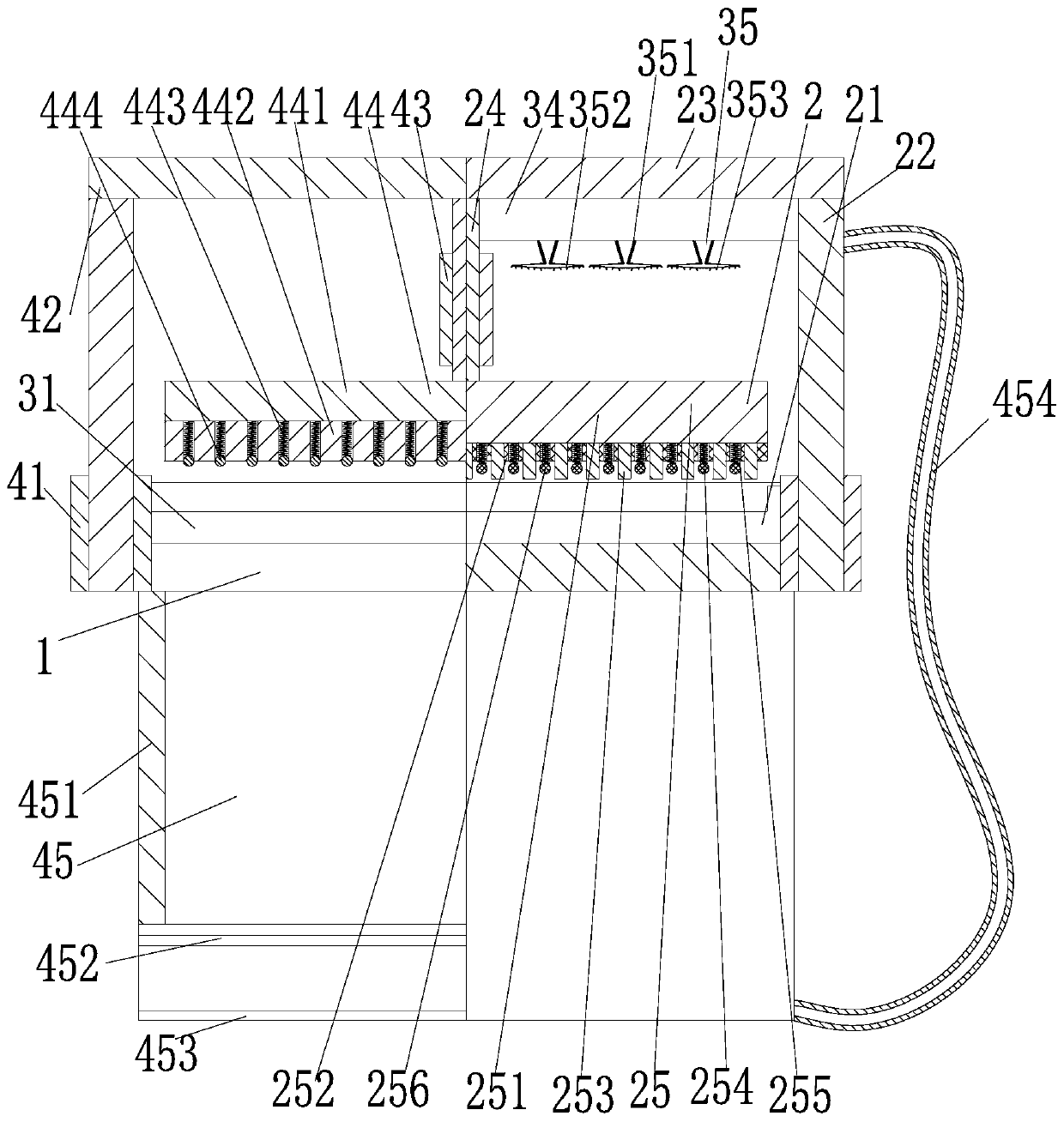

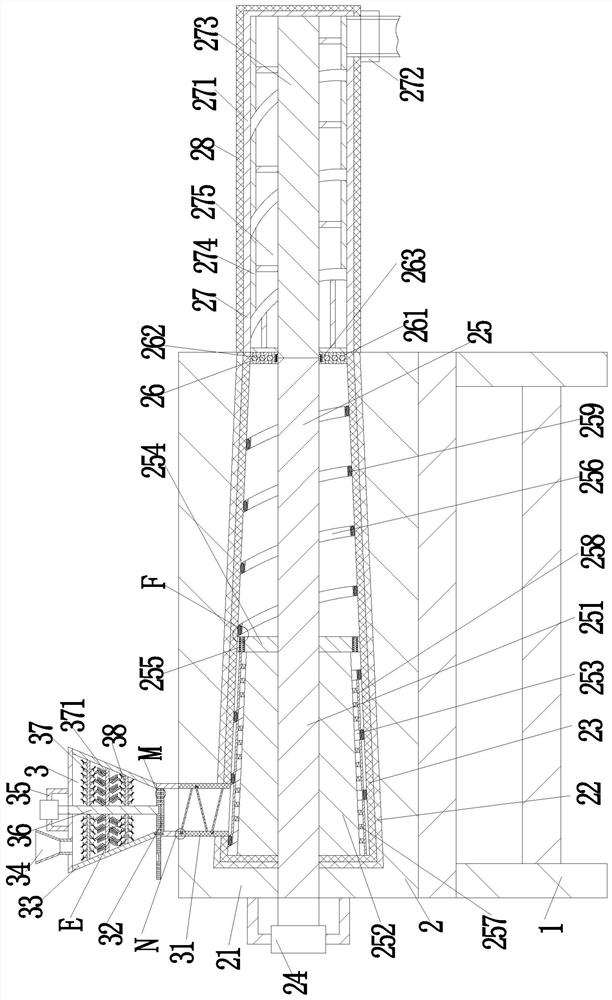

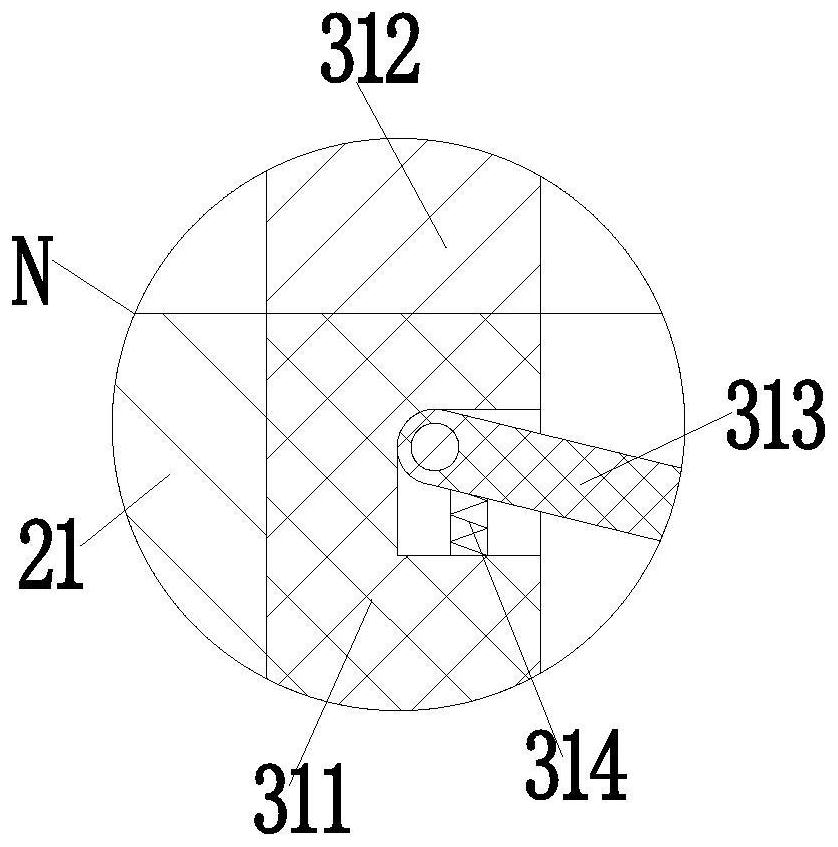

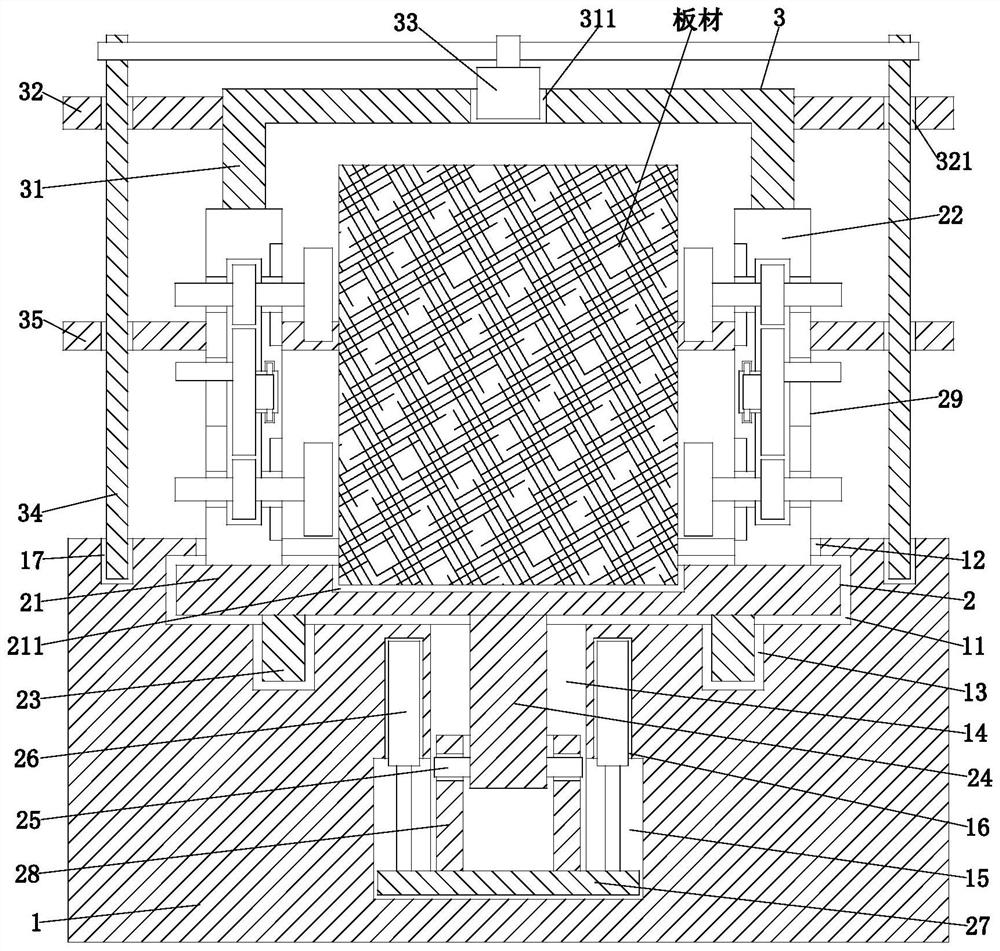

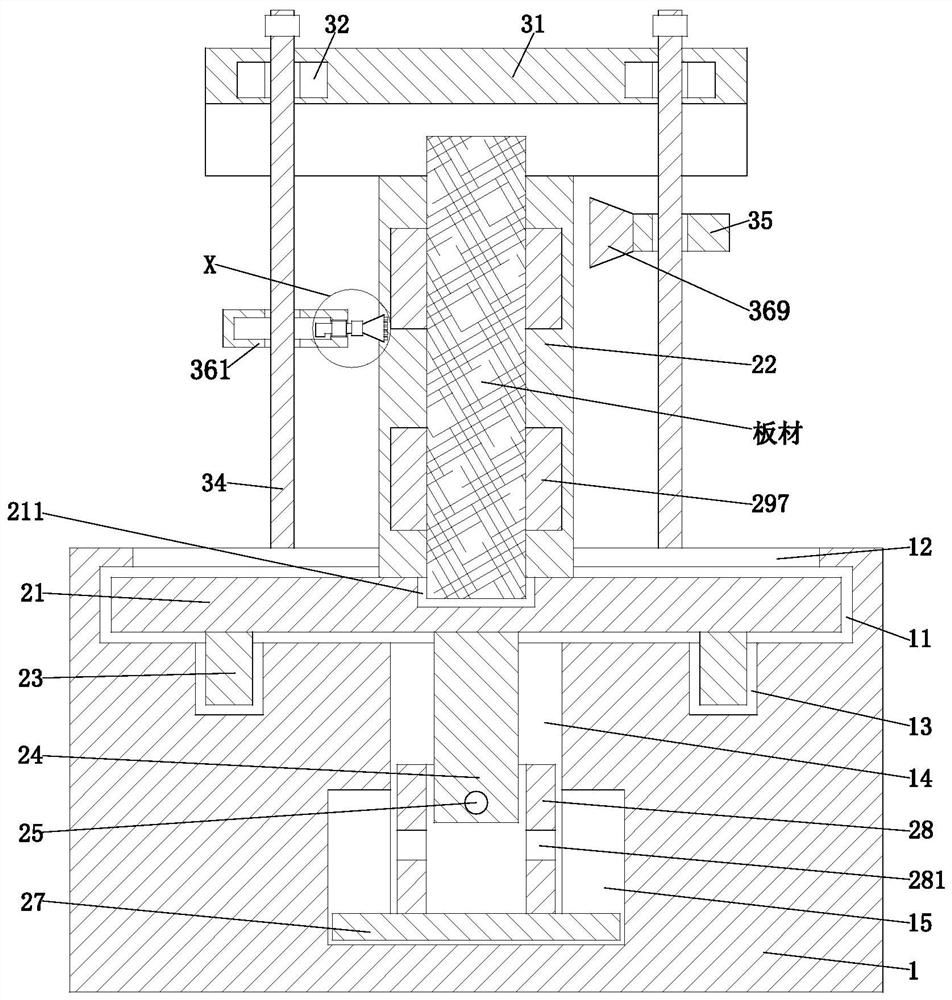

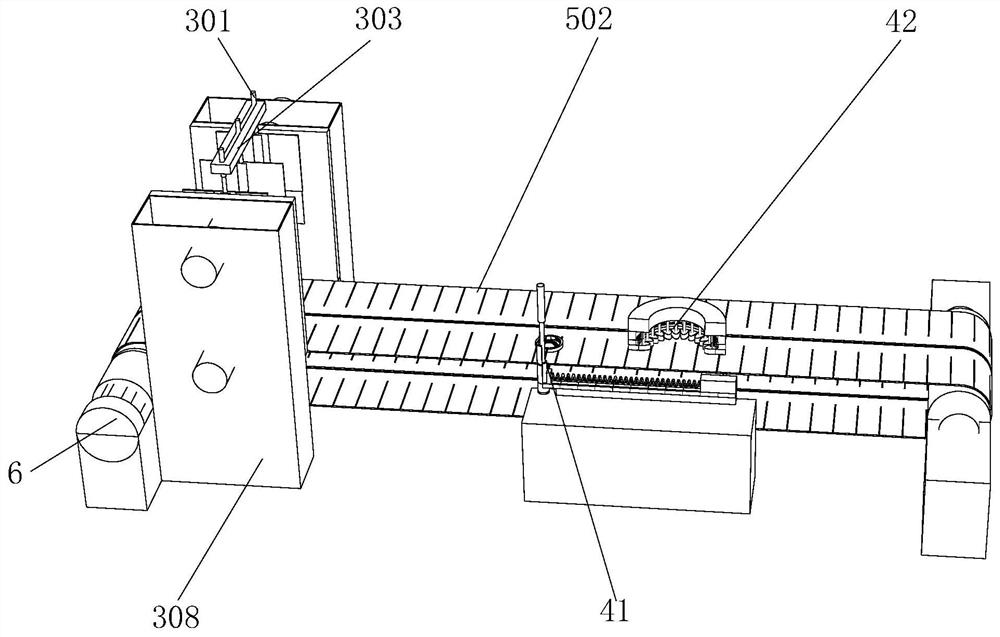

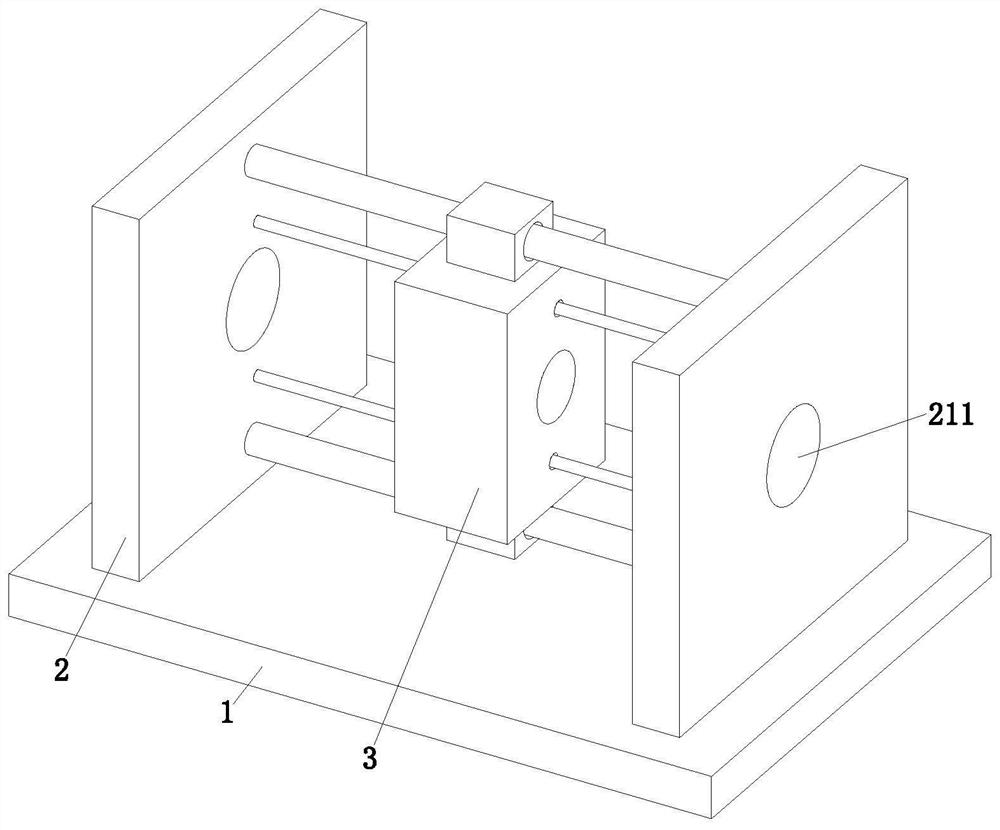

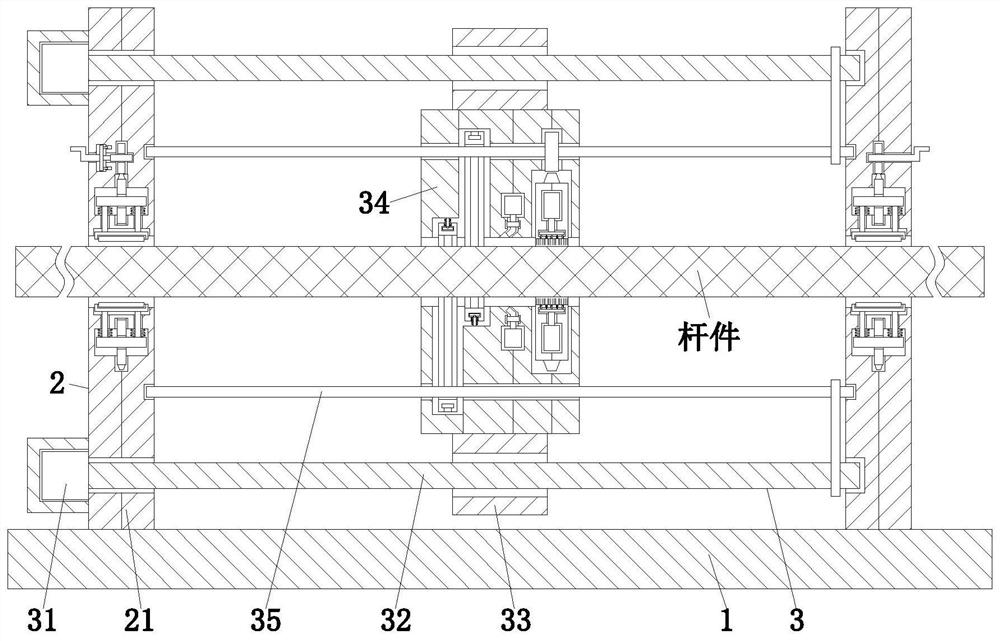

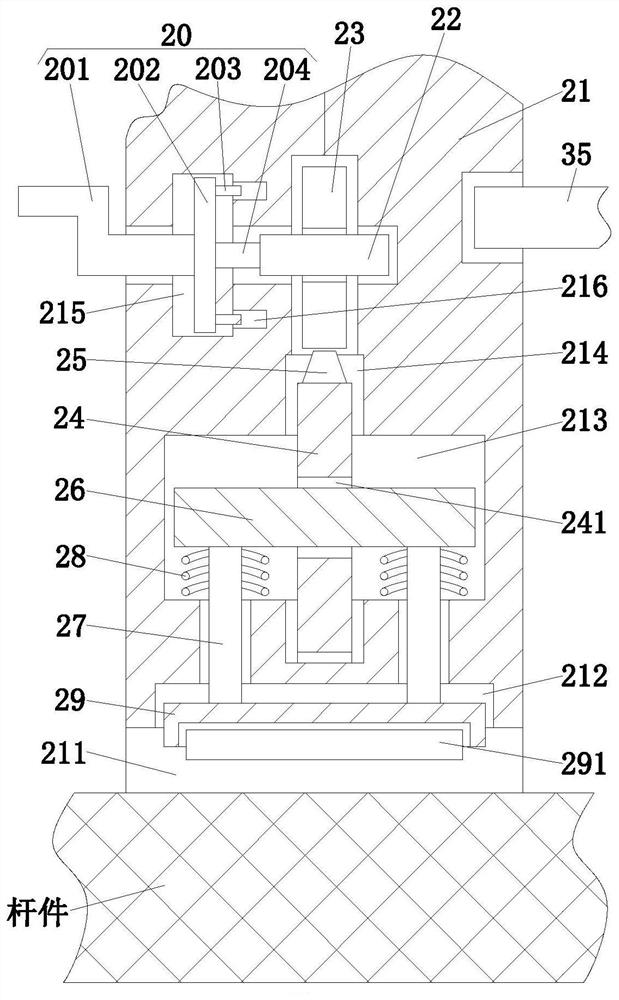

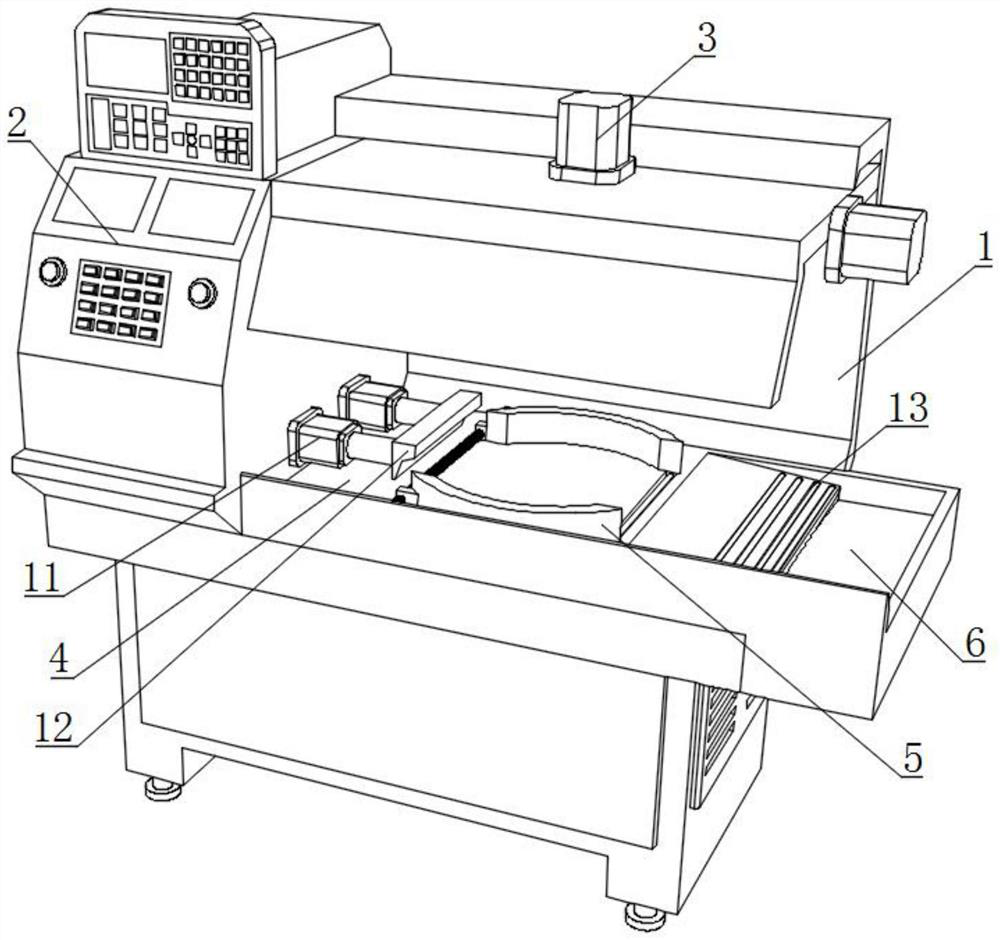

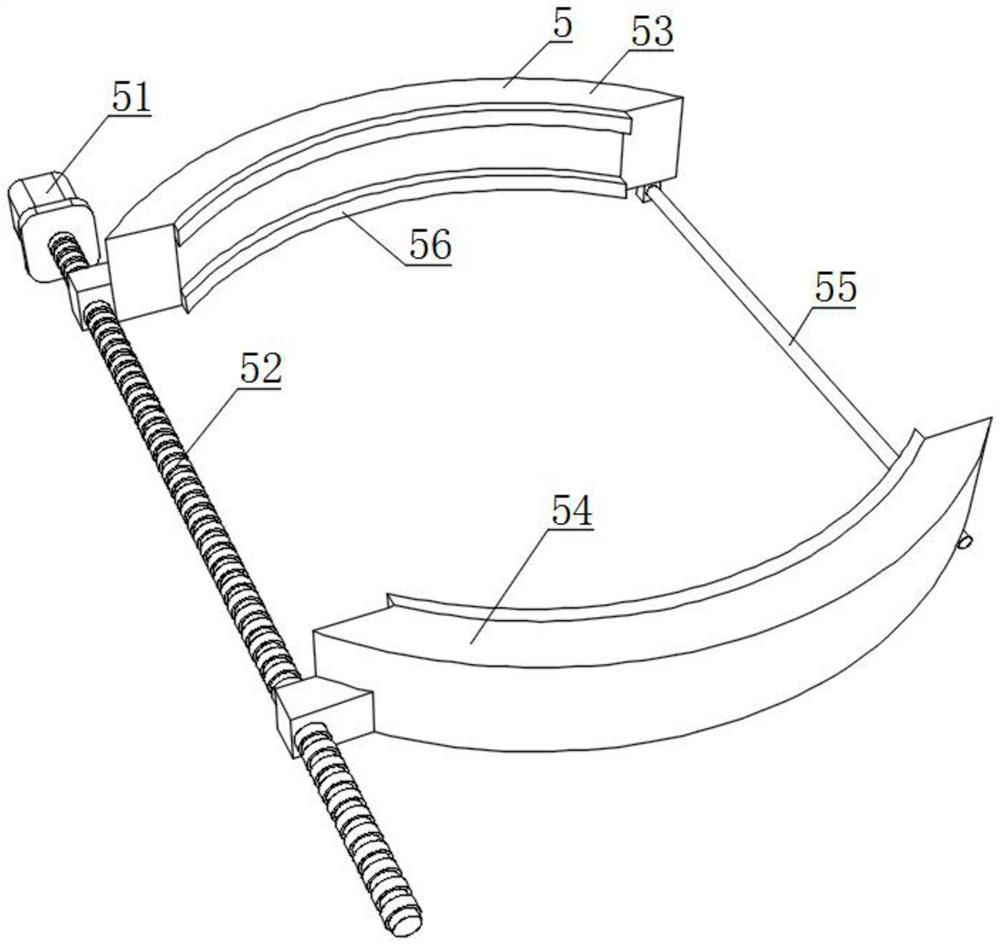

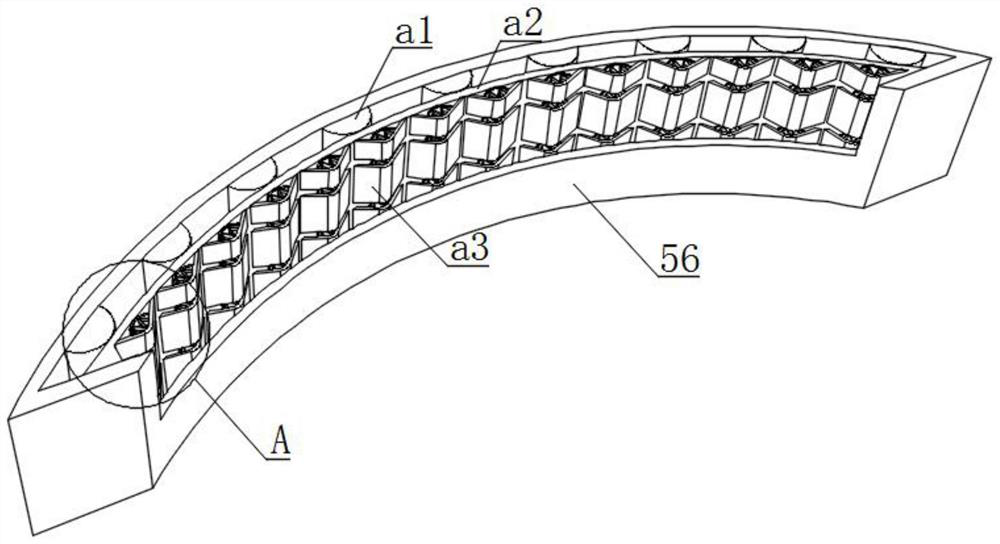

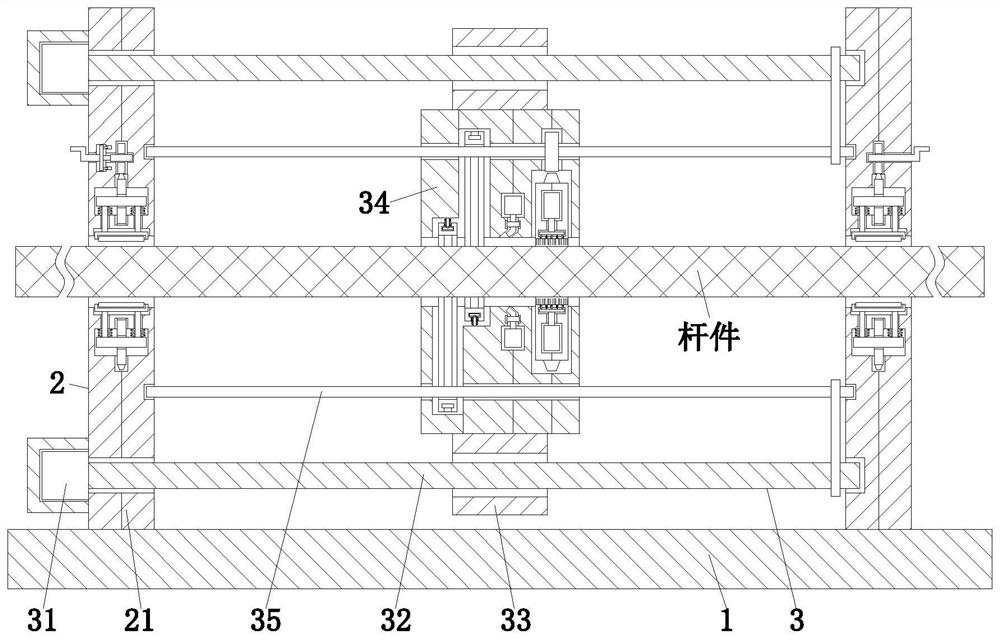

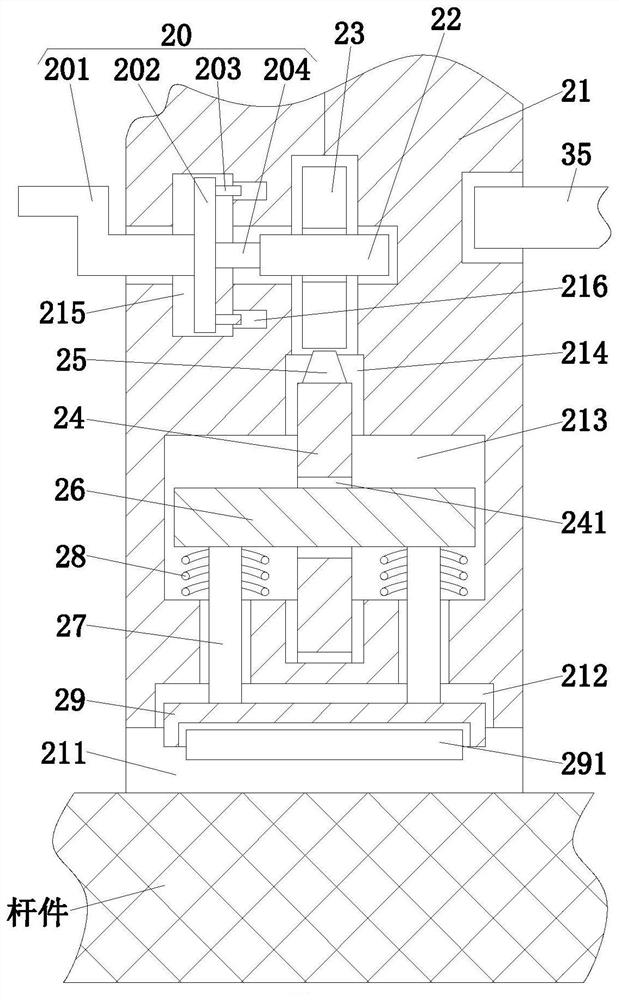

A production and processing machine for photographic mobile tripod bracket rods

ActiveCN113118945BPrevent affecting processing efficiencyImprove stabilityGrinding carriagesLiquid surface applicatorsEngineeringStructural engineering

The present invention provides a kind of photographic mobile tripod rod production and processing machine, including a base, a support unit and an execution unit. When the rods are manufactured and processed, they are mostly polished by manual processing, but the rods cannot be completely fixed during manual grinding, and the stability of the rods cannot be ensured, which may easily cause the rotation or displacement of the rods, thus affecting processing efficiency, and manual grinding cannot remove the debris on the outer wall of the rod in time, so the debris is easy to cause damage to the rod; when the current rod is coated with anti-corrosion coating, it is generally applied manually, and the anti-corrosion coating contains a lot of chemical Therefore, long-term exposure of workers is easy to cause harm to the human body, and manual application cannot ensure the uniformity of anti-corrosion coatings, which will affect the anti-corrosion performance of the rods in the later stage".

Owner:NANJING FORESTRY UNIV

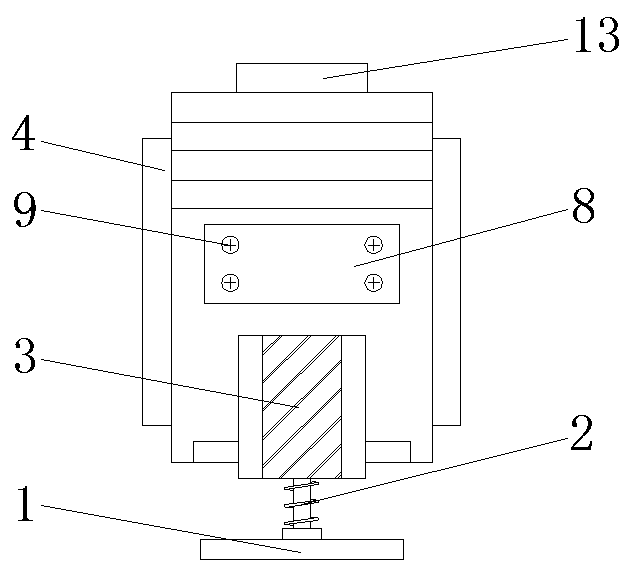

Spun yarn waxing device used for spinning and capable of preventing yarn breakage

The invention discloses a spun yarn waxing device used for spinning and capable of preventing yarn breakage and relates to the technical field of spun yarn waxing. The device comprises an anti-slidingblock and a first connecting rod, a support block is mounted above the anti-sliding block, a base is arranged above the support block, and vent holes are formed in the outer side of the base. A fixing block, an air cylinder, a piston, a straight rod, an ejector rod, a casing, a hydraulic rod and a wax groove are arranged in the spun yarn waxing device used for spinning and capable of preventing yarn breakage, a user can fix the air cylinder above the base through the fixing block, the user can slide the piston up and down in the air cylinder, the piston can well support the straight rod, thestraight rod can well support the ejector block, then, during use, the hydraulic rod can drive the wax groove to telescope upwards with reduction of a wax block so as to enable the wax block to make contact with spun yarn, the user can use the device conveniently, non-uniform waxing of the spun yarn due to reduction of the wax block can be well avoided, and the processing quality of the device isenhanced.

Owner:杨国丽

Heat-resistant PVC material processing device and method

InactiveCN113771252AImprove the mixing effectImprove cleaning effectProcess engineeringManufacturing engineering

The invention relates to the technical field of heat-resistant material processing, and discloses a heat-resistant PVC material processing device and method. The heat-resistant PVC material processing device comprises a base, wherein a processing box is fixedly connected to the top of the base, a feeding hopper is arranged at the center axis of the top of the processing box, the feeding hopper is communicated with the center axis of the top of the processing box, and a rotating shaft is arranged at the center axis in the processing box. According to the heat-resistant PVC material processing device and method, when a large quantity of materials enter the processing box and stay on an elastic screen, the elastic screen can deform elastically under the action of gravity pressure, part of the materials can pass through screen holes when the elastic screen deforms, then the weight on the elastic screen is changed, and in this state, the elastic screen can conduct deformation vibration repeatedly, so that the materials can uniformly enter the processing box, and meanwhile the situation that the materials are accumulated on the elastic screen and the processing efficiency is influenced is prevented.

Owner:高力功

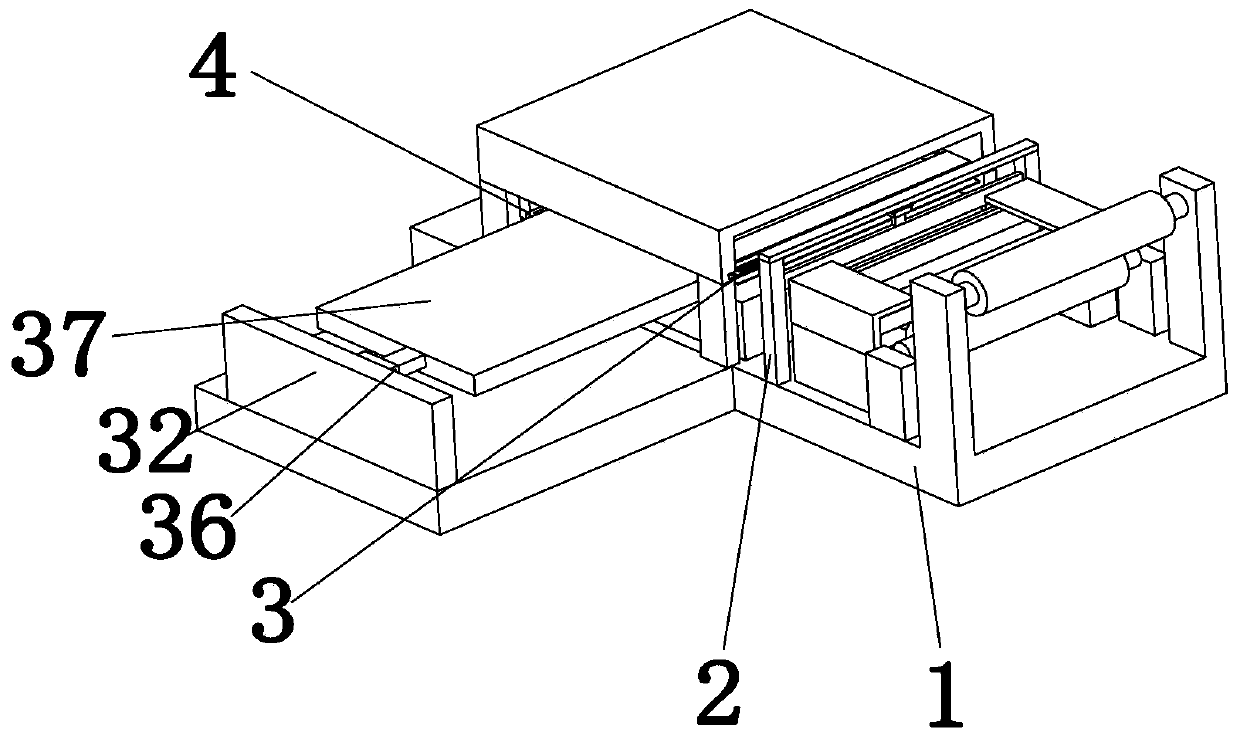

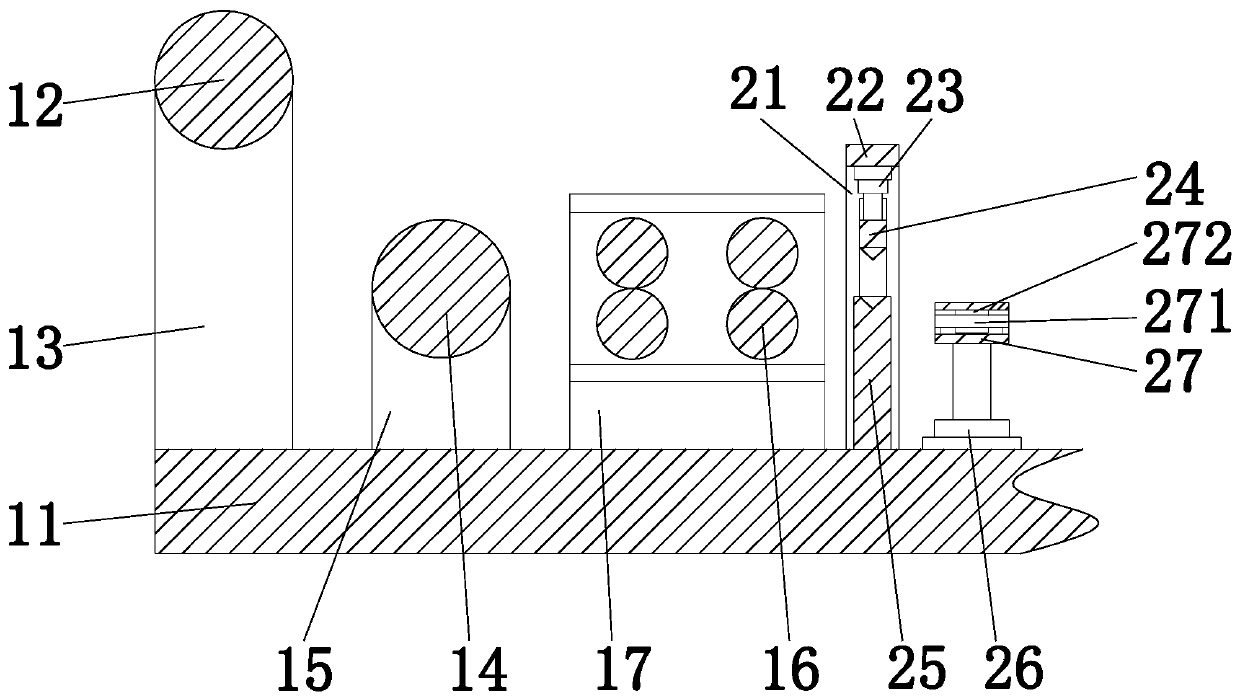

Printing paper processing system

ActiveCN111531630AAchieve horizontal cuttingAvoid the problem of frequent tool changesMetal working apparatusProcess engineeringIndustrial engineering

The invention relates to a printing paper processing system which comprises a compression guiding rack, a transverse cut-off mechanism, a longitudinal cut-off mechanism and a stretching collecting mechanism. The printing paper processing system can solve the problems in a processing operation of printing paper that a, in a conventional printing paper cutting process, a process flow is relatively tedious as the printing paper of one specification needs to correspond to a set of tools and it is needed to replace tools for printing paper of different specifications; and b, the edge of the printing paper is treated unreasonably in existing equipment, and in a production process, subsequent use of the printing paper is affected as the edge of the printing paper may be damaged to different extents.

Owner:长兴天誉包装股份有限公司

Double-spindle drilling machine facilitating rapid machining

PendingCN113695625AFast processingEasy to processBoring/drilling componentsMaintainance and safety accessoriesMachineRapid tooling

The invention discloses a double-spindle drilling machine facilitating rapid machining. The double-spindle drilling machine comprises a drilling machine body, the drilling machine body comprises a first machine body and a second machine body, a machining spindle is rotationally arranged on a workbench at the joint between the first machine body and the second machine body, and a first machining mechanism and a second machining mechanism are arranged on the first machine body and the second machine body respectively; and a first driving mechanism and a second driving mechanism for driving the first machining mechanism and the second machining mechanism to be close to or far away from the machining spindle are arranged on the first machine body and the second machine body respectively. The first machining mechanism and the second machining mechanism are used for machining a workpiece simultaneously or in succession, so that machining of the workpiece is rapidly completed, and the machining effect is improved.

Owner:浙江巨臣机电科技有限公司

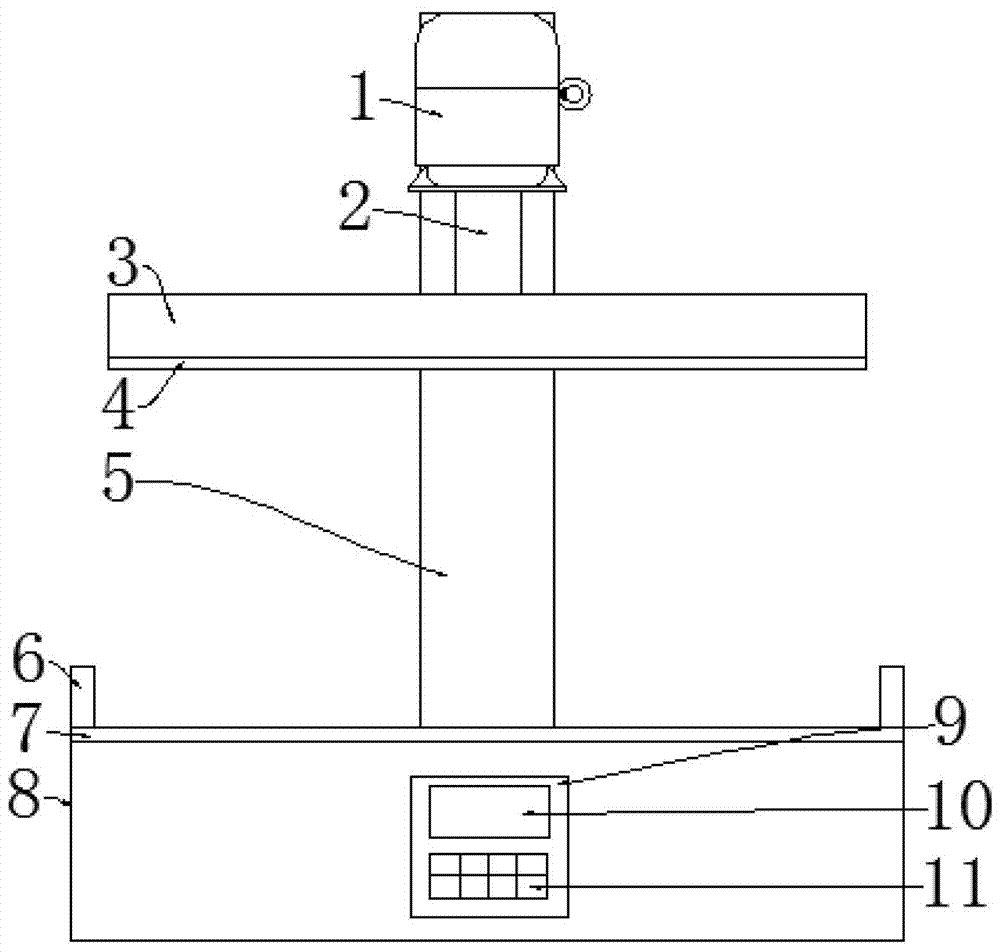

Flocking fabric thermo printing device

PendingCN107538900AGuarantee processing qualityAvoid damageRotary pressesPrinting press partsTemperature controlAir pump

The invention discloses a flocking fabric thermo printing device which comprises a base, a support column and a pump seat, wherein a working table is arranged on the base, a gravity sensor is arrangedin the working table, locating blocks are arranged on the two sides of the working table, a control main engine is arranged on the side surface of the base, a display screen is arranged on the surface of the control main engine, and a control keyboard is arranged by the side of the display screen. The flocking fabric thermo printing device has the advantages that by the aid of a feedback controlloop formed by a temperature sensor, the control main engine and a heating plate, automatic temperature control heating can be realized, constant-temperature thermo printing can be performed to the fabric, the thermo printing processing quality is guaranteed, at the same time, by the aid of a feedback control loop formed by the gravity sensor, the control main engine and an air pump, the intensityduring thermo printing can be controlled to the preset value in real time, the situation that the fabric is damaged due to too large intensity or the processing efficiency is affected by too small intensity is prevented, the thermo printing processing quality is further guaranteed, and the use is convenient.

Owner:ZHEJIANG YONGHE TEXTILE FLOCKING CO LTD

An integrated processing system for the recycling and reuse of packaging cardboard boxes

ActiveCN110695051BComplete humidity controlExpand the spraying areaSolid waste disposalLiquid spraying apparatusCarton flowCarton

The invention relates to an integrated processing system for recycling packaging cartons. The integrated processing system comprises a workbench, a flattening device, a humidifying device and a shaping device. The flattening device is mounted on the upper end face of the right side of the workbench. The humidifying device is mounted on the upper end face of the middle of the workbench. The shapingdevice is mounted at the left end of the humidifying device. A first telescopic support is adjusted to enable a first electric push rod to drive a rubber plate to squeeze a carton, and the surface ofthe carton is cut through a cross tool, so that complete humidification is facilitated; a metal spring is squeezed to generate opposite acting force to drive a rubber ball to squeeze the carton to beseparated from a pressing plate to enter the humidifying device, so that the situation that the carton is clamped on the rubber plate and the cross tool, and consequentially, the flattening process is affected is solved; and the carton is completely humidified through a water-spraying main frame and a flower-type spray head, and redundant water in the carton flows through a base plate and is finally delivered into the water-spraying main frame through a water delivery pipe, so that water is recycled.

Owner:泰州市合兴纸业有限公司

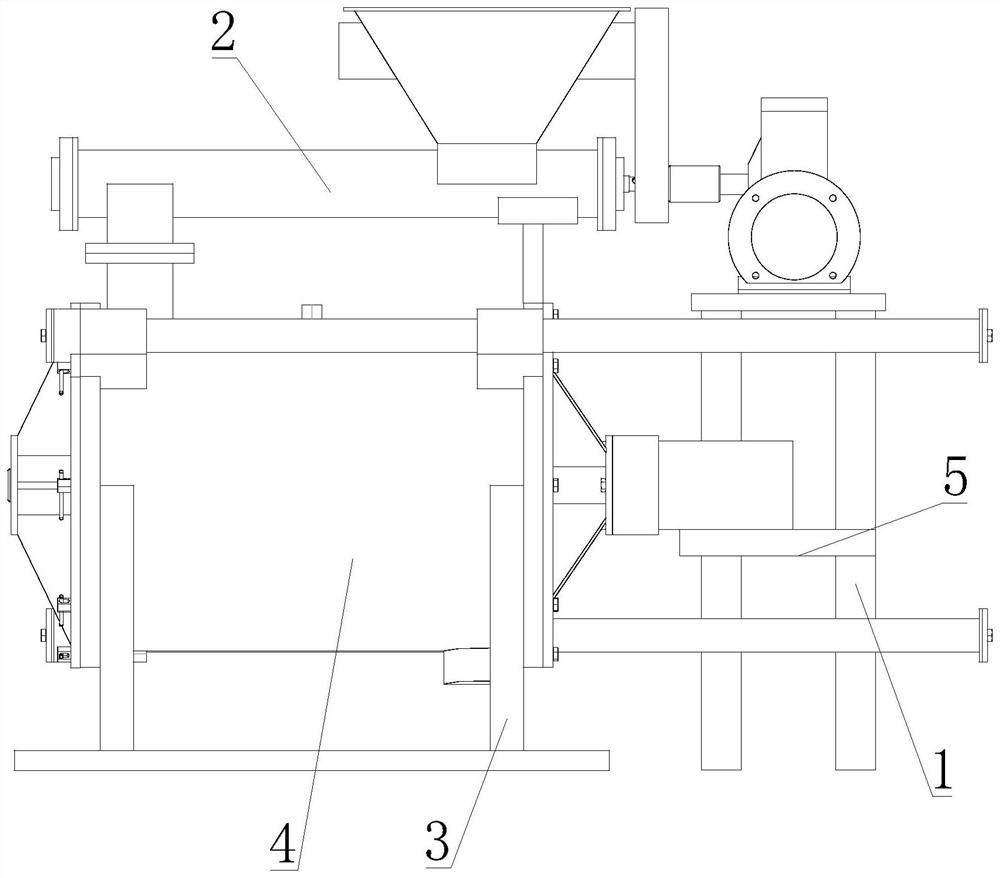

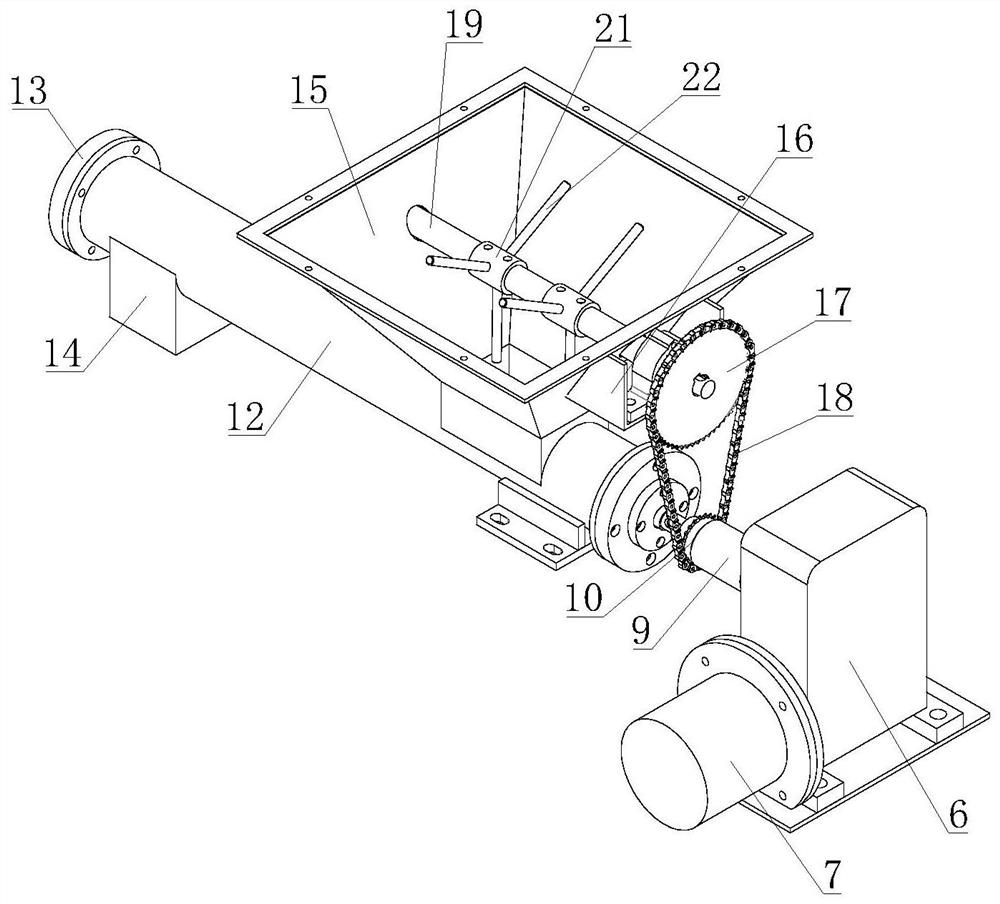

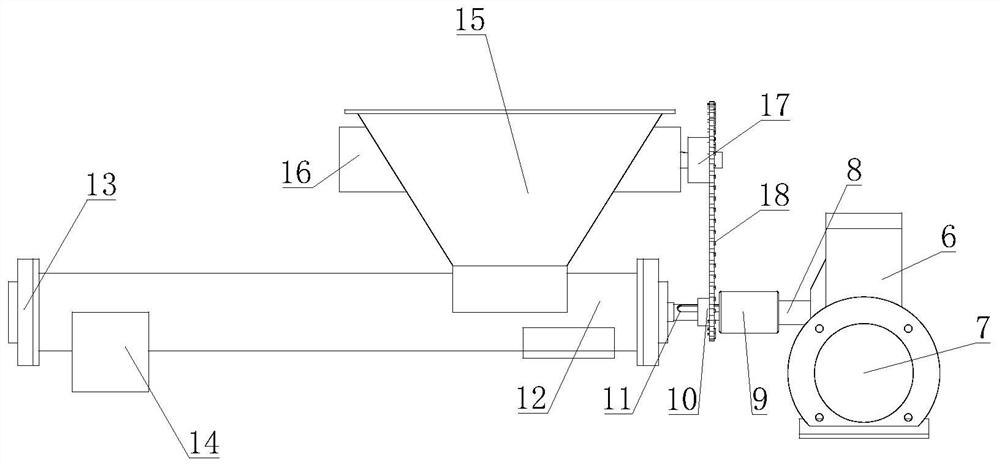

Disc type sand mill with long service life and its processing technology

The invention discloses a disc sand mill with long service life and its processing technology. It comprises a main body frame and a mill base. machine assembly, the feed port of the mill assembly is connected to the discharge port of the feeding assembly; the feeding assembly includes a reducer and a feeding cylinder, the reducer is fixedly installed on the main frame, The input end is fixedly installed with a first motor, the output end of the reducer is fixedly connected with a first connecting shaft, and a shaft coupling is fixedly installed on the first connecting shaft, and the upper material cylinder is horizontally arranged above the mill assembly. The end cover of the grinding cylinder and the sanding seat that can be disassembled flexibly are set to facilitate timely and rapid cleaning of the interior of the sanding cylinder and the sanding seat, effectively ensuring the cleaning of the sanding cylinder and the sanding seat, and preventing the sanding cylinder from being Adhesion of materials or abrasives on the sanding base will affect the sanding process efficiency and reduce the service life.

Owner:安徽儒特实业有限公司

Non-tempering biomass feeding device and method capable of preventing tempering

InactiveCN113669751AAvoid cloggingPrevent affecting processing efficiencySolid fuel combustionLump/pulverulent fuel feeder/distributionReciprocating motionMaterials science

The invention relates to the technical field of burners, and provides a non-tempering biomass feeding device and method capable of preventing tempering. The non-tempering biomass feeding device capable of preventing tempering comprises a shell, a switching mechanism, a transmission mechanism, a dredging mechanism and a speed regulating mechanism, wherein a feeding port is formed in the top of the shell; a conveying shaft is movably connected to the lower end of the feeding port; a rotating shaft is fixedly connected to the front end of the conveying shaft; the lower end of the rotating shaft is movably connected with the switching mechanism; the left side of the switching mechanism is movably connected with the transmission mechanism; and the upper end of the transmission mechanism is movably connected with the bottom of the dredging mechanism. According to the non-tempering biomass feeding device and method capable of preventing tempering, large-size materials stacked in the feeding port are pushed upwards, small-size materials fall downwards in a gap, and due to the fact that a T-shaped rod reciprocates, an ejector block also reciprocates through the transmission effect of an internal structure, so that the effects that the materials are automatically dredged in the feeding process, and the situation that the materials are blocked to affect the machining efficiency is prevented are achieved.

Owner:文亮

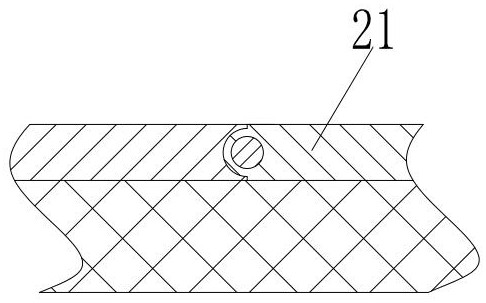

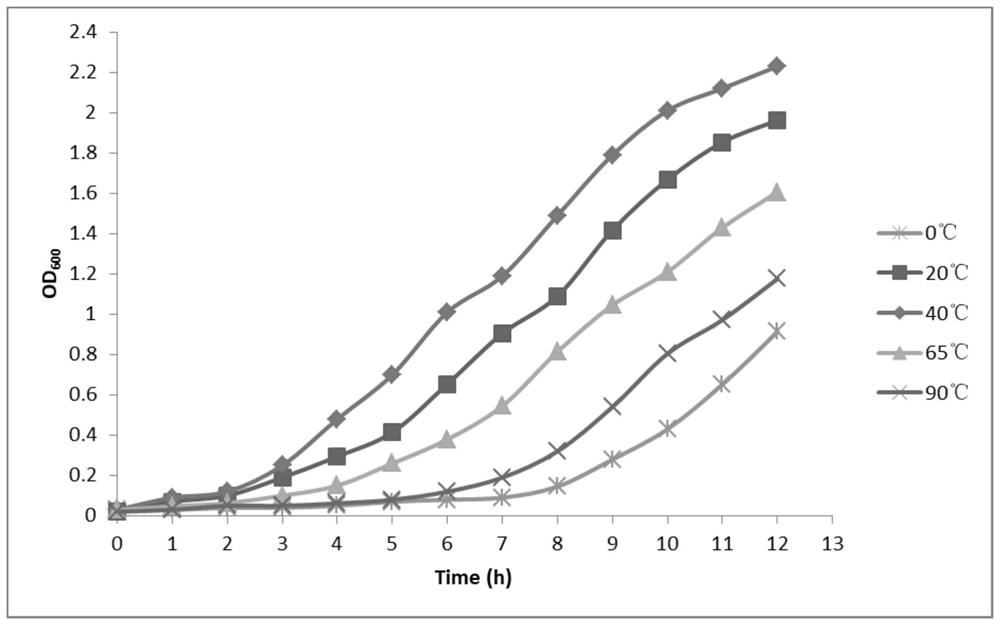

Microorganism-loaded carbon source slow-release wax as well as preparation method and application thereof

PendingCN112553188AReduce ammonia nitrogenReduce nitrate nitrogenBacteriaWater treatment compoundsBiotechnologyChemical oxygen demand

The invention relates to the technical field of water treatment, and discloses microorganism-loaded carbon source slow-release wax as well as a preparation method and an application thereof. The carbon source slow-release wax comprises a waxy carrier, a non-water-soluble microbial carbon source and an auxiliary agent which are distributed in the waxy carrier, and paenibacillus distributed in the waxy carrier, The paenibacillus is named as DFB2-6, is preserved in China General Microbiological Culture Collection Center on August 21, 2020, has a preservation number of CGMCC No.20535, and is namedas Paenibacillus harenae in a classified manner. The carbon source slow-release wax can slowly release a carbon source after being put into a to-be-treated water body, cannot cause increase of COD (Chemical Oxygen Demand) of the water body, can provide a continuous, on-demand and controllable carbon source for the paenibacillus, keeps balance of carbon, nitrogen and phosphorus, and is beneficialto growth and propagation of the paenibacillus.

Owner:HANGZHOU XIUCHUAN TECH CO LTD

A kind of printing paper processing technology

ActiveCN111516037BAchieve horizontal cuttingAvoid the problem of frequent tool changesMetal working apparatusProcess engineeringIndustrial engineering

The invention relates to a printing paper processing technology, which is mainly completed by a printing paper processing equipment. The printing paper processing equipment includes a pressing guide frame, a transverse cutting mechanism, a longitudinal cutting mechanism and a stretching and collecting mechanism. The present invention can solve the following problems in the processing of printing paper: a. In the cutting process of traditional printing paper, a set of cutting tools is required for printing paper of one specification, and different cutting tools need to be replaced for printing paper of different specifications, and the process flow is comparatively It is cumbersome, b. In the existing equipment, the edge of the printing paper is not properly treated. During the production process, the edge of the printing paper may be damaged to varying degrees, which will affect the subsequent use of the printing paper.

Owner:东莞市新锐源防伪科技有限公司

Polymerization device capable of rapid transportation and multi-angle processing and operation method of polymerization device

PendingCN109436761AImprove compactnessEfficient aggregate operationConveyor partsEngineeringPolymerization

The invention discloses a polymerization device capable of rapid transportation and multi-angle processing and an operation method of the polymerization device. The polymerization device comprises supporting blocks and fixing plates, springs are arranged on the upper parts of the supporting blocks, and connecting plates are installed on the upper parts of the springs; shells are arranged on the right sides of the connecting plates, and a discharging port is formed on the lower parts of the shells; the connecting plates and the shells are connected in a welded mode, hooks are installed on the right side of the discharging port, and installation holes are formed in the right sides of the hooks; fixing screws are arranged on the right sides of the fixing plates, and the fixing plates are located on the right sides of the shells; the fixing plates and the shells are connected in an attached mode, a processing groove is formed in the inner sides of the shells, inclined plates are arranged below the processing groove, and an air inlet is formed above the processing groove. The polymerization device capable of rapid transportation and multi-angle processing has the characteristics that internal products can be operated in all-around multi-angle polymerization, materials can be quickly transported, and the jitter frequency is small when the polymerization device is used.

Owner:JIANGSU HAIYANG NYLON NEW MATERIAL CO LTD

Numerically-controlled machine tool with material guide channel

PendingCN114851028ASolve the inconvenient positioningStable deliveryGrinding carriagesGrinding drivesNumerical controlPolishing

The invention discloses a numerical control machine tool with a material guide channel, and relates to the technical field of numerical control machine tools, the numerical control machine tool comprises a numerical control machine tool body, the numerical control machine tool body is composed of a control device, a polishing mechanism and an operation table, and the bottom end of the right side of the control device is connected with the left side of the operation table in a welding mode; the grinding mechanism is arranged above the operation table, a positioning mechanism is arranged on the upper surface of the operation table, a material guide channel is welded to the right side of the operation table, and a bearing mechanism is fixedly installed on the right side of the material guide channel and comprises a material receiving box and a bearing pressure relief assembly. Through the cooperation of stretching and retracting of the hydraulic device and the ejector plate, a machined workpiece is pushed to move, rapid conveying and guiding of the workpiece are assisted through inclination of the guide channel and rotation of the guide sliding roller, buffering is conducted in cooperation with the bearing pressure relief assembly, and therefore stable conveying of the workpiece is guaranteed, and workpiece abrasion caused by collision is prevented.

Owner:张凯

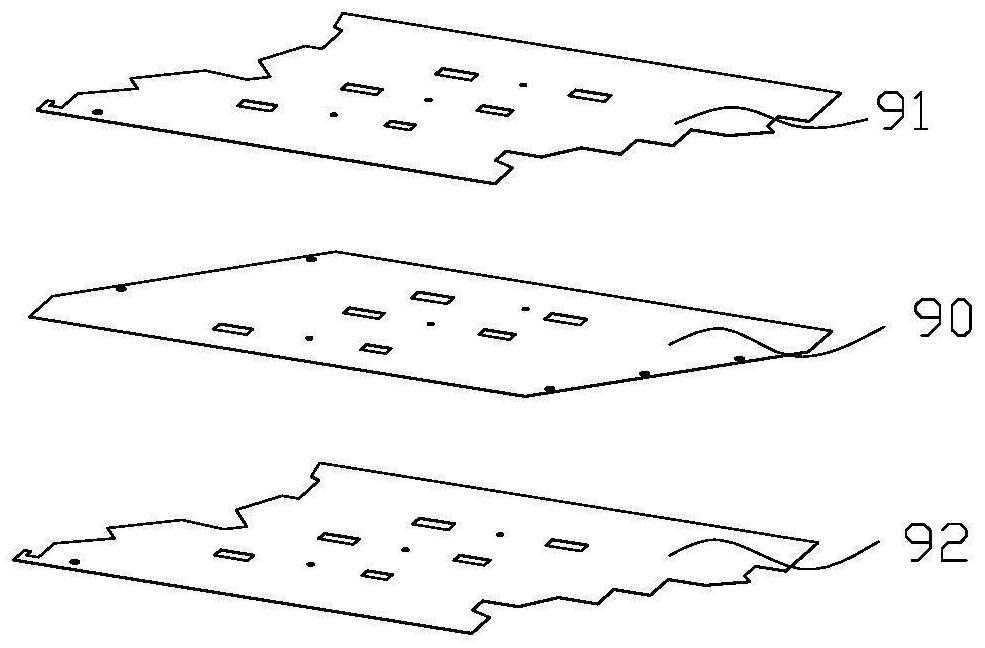

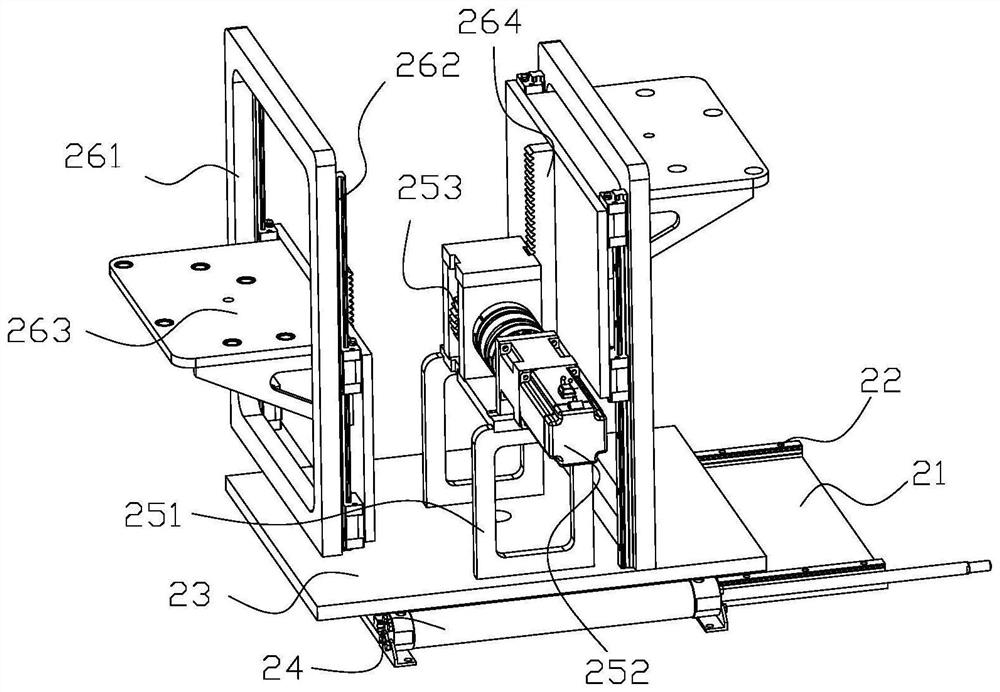

Circuit substrate feeding device and method thereof

InactiveCN112153821AReduce waiting timeSmooth connectionCircuit precursor manufactureHemt circuitsControl theory

The invention belongs to the technical field of circuit substrate automatic production, and relates to a circuit substrate feeding device which comprises a circuit substrate bottom plate, a circuit substrate sliding rail, a circuit substrate feeding support, a circuit substrate moving air cylinder, a driving assembly, a first circuit substrate feeding assembly, a second circuit substrate feeding assembly and a circuit substrate transferring assembly. The circuit substrate feeding support is arranged on the circuit substrate bottom plate through the circuit substrate sliding rail, and the circuit substrate moving air cylinder is arranged on a machine frame. The driving assembly is arranged in the middle of the circuit substrate feeding support and used for driving the first circuit substrate feeding assembly and the second circuit substrate feeding assembly to act. The circuit substrate transfer assembly is used for transferring a circuit substrate. The feeding device and the method have the advantages that the feeding time of the circuit substrate is saved, the feeding efficiency is improved, and the stability and accuracy of copper film conveying are improved.

Owner:朱雷

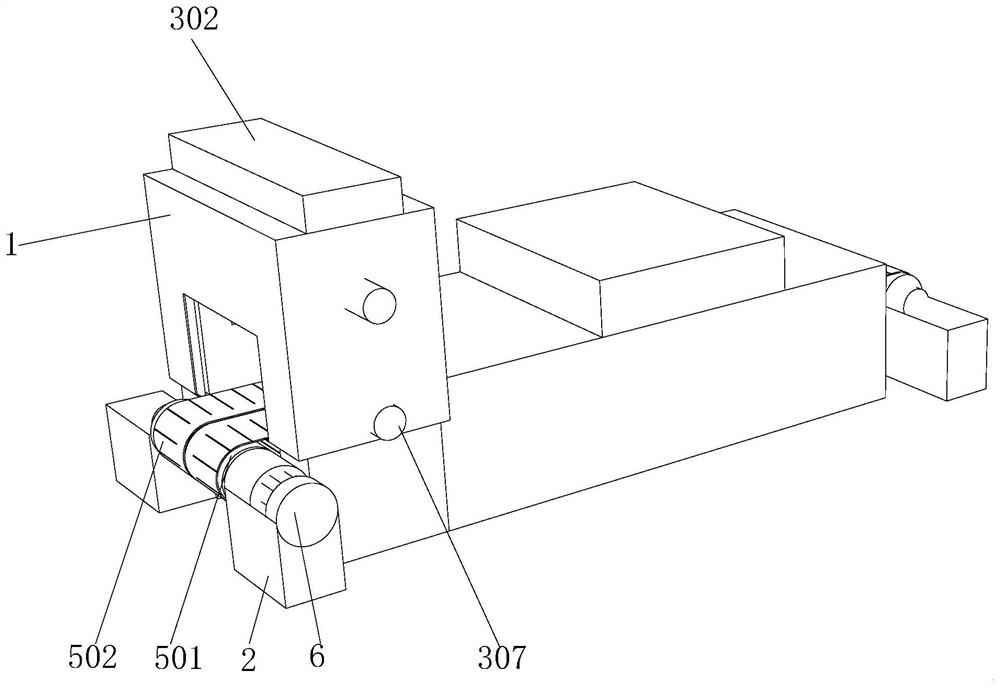

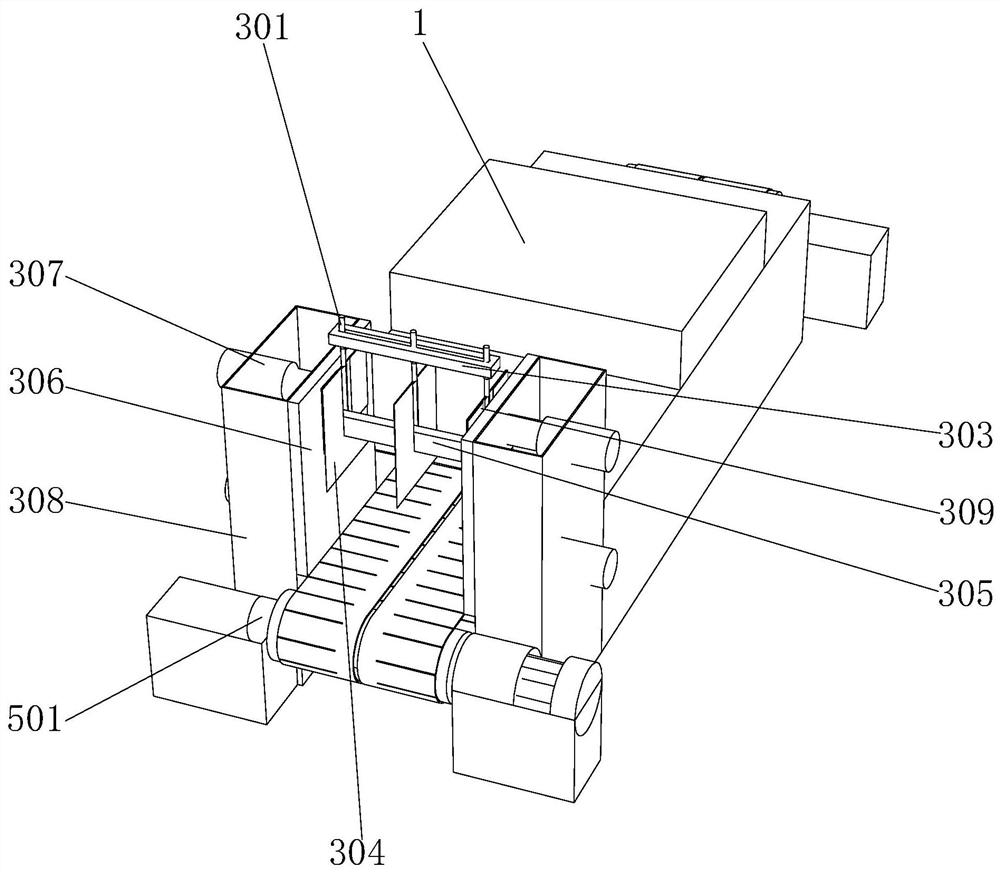

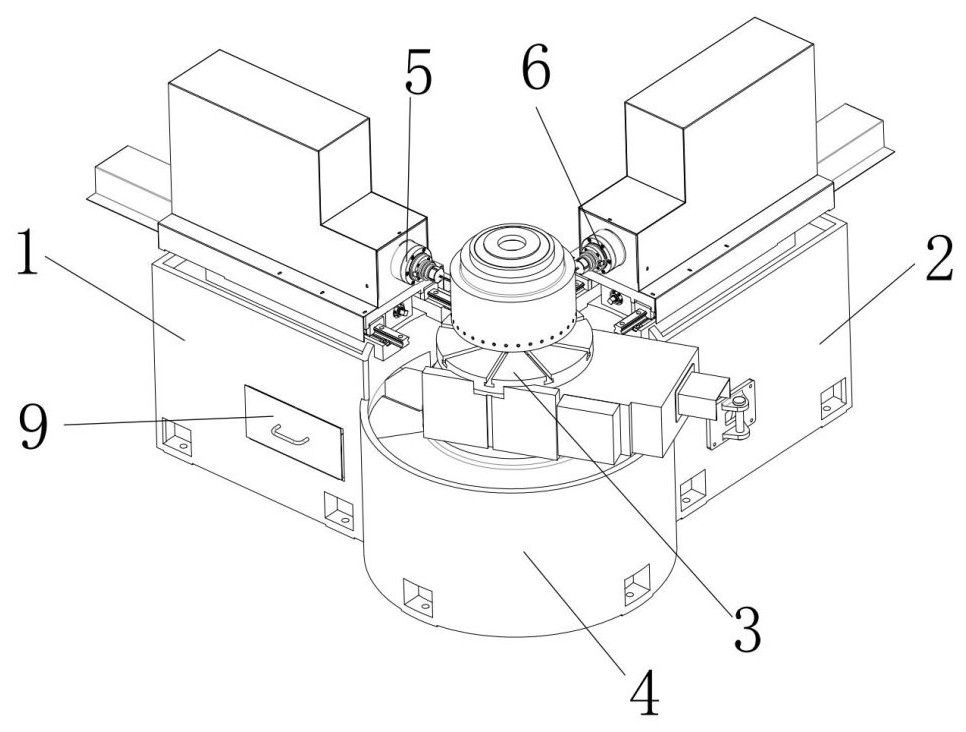

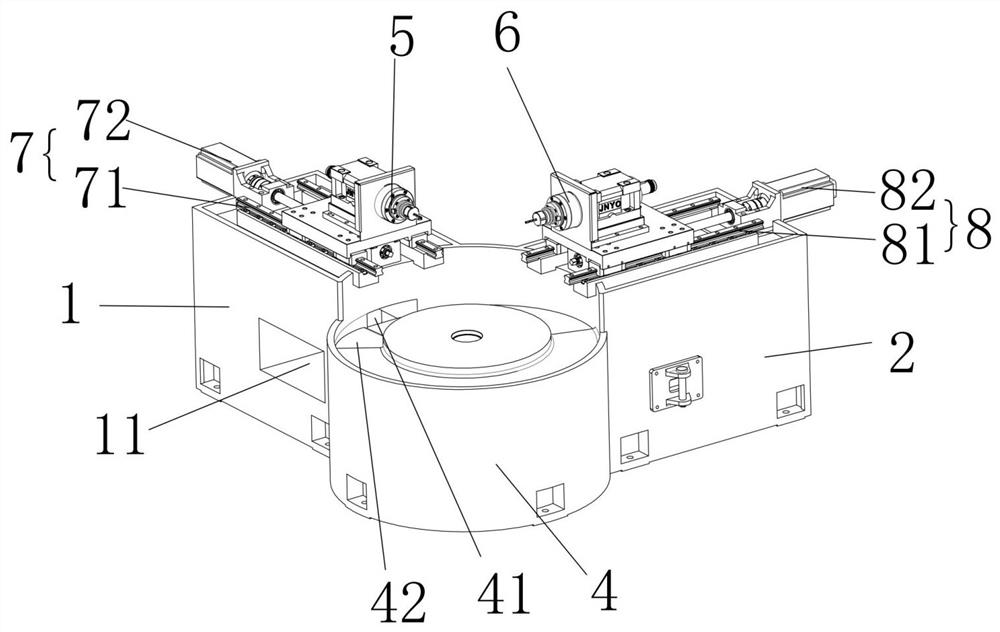

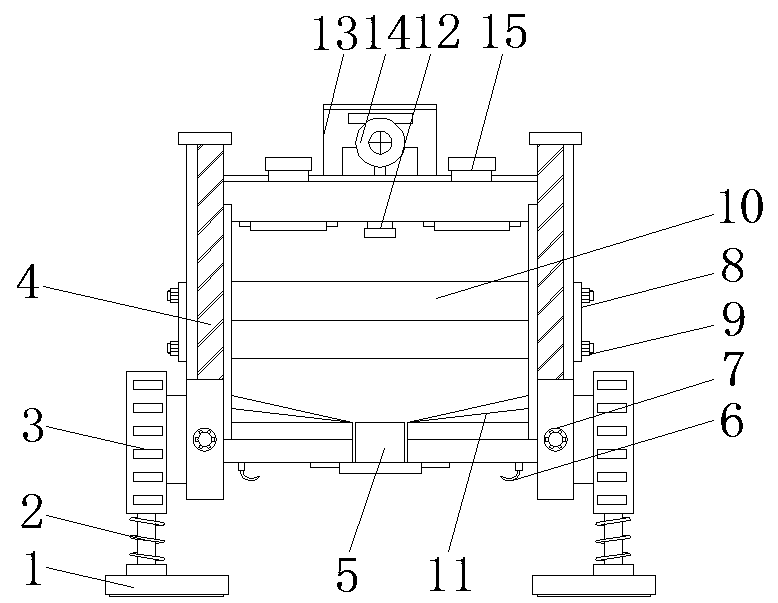

Manufacturing and processing machine for photographing movable triangular support rod piece

ActiveCN113118945APrevent affecting processing efficiencyImprove stabilityGrinding carriagesLiquid surface applicatorsMachiningIndustrial engineering

The invention discloses a manufacturing and processing machine for a photographing movable triangular support rod piece. The manufacturing and processing machine comprises a base, a supporting unit and an execution unit, the supporting unit is installed at the upper end of the base, and the execution unit is arranged on the inner side wall of the supporting unit. The machine can solve the problems that when a traditional rod piece is manufactured and processed, the rod piece is mostly ground in a manual machining mode, the rod piece cannot be completely fixed during manual grinding, the stability of the rod piece cannot be ensured, rotation or displacement of the rod piece is likely to be caused, the machining efficiency is influenced, and chippings on the outer wall of the rod piece cannot be removed in time through the manual grinding, so that the chippings are prone causing damage to the rod piece; and at present, when anticorrosive paint is smeared on the rod piece, manual smearing is generally adopted, the anticorrosive paint contains a large number of chemical components, therefore, a human body is prone to being hurt when workers make contact with the anticorrosive paint for a long time, the uniformity of the anticorrosive paint cannot be guaranteed through manual smearing, and the later-stage anticorrosive performance of the rod piece is affected.

Owner:NANJING FORESTRY UNIV

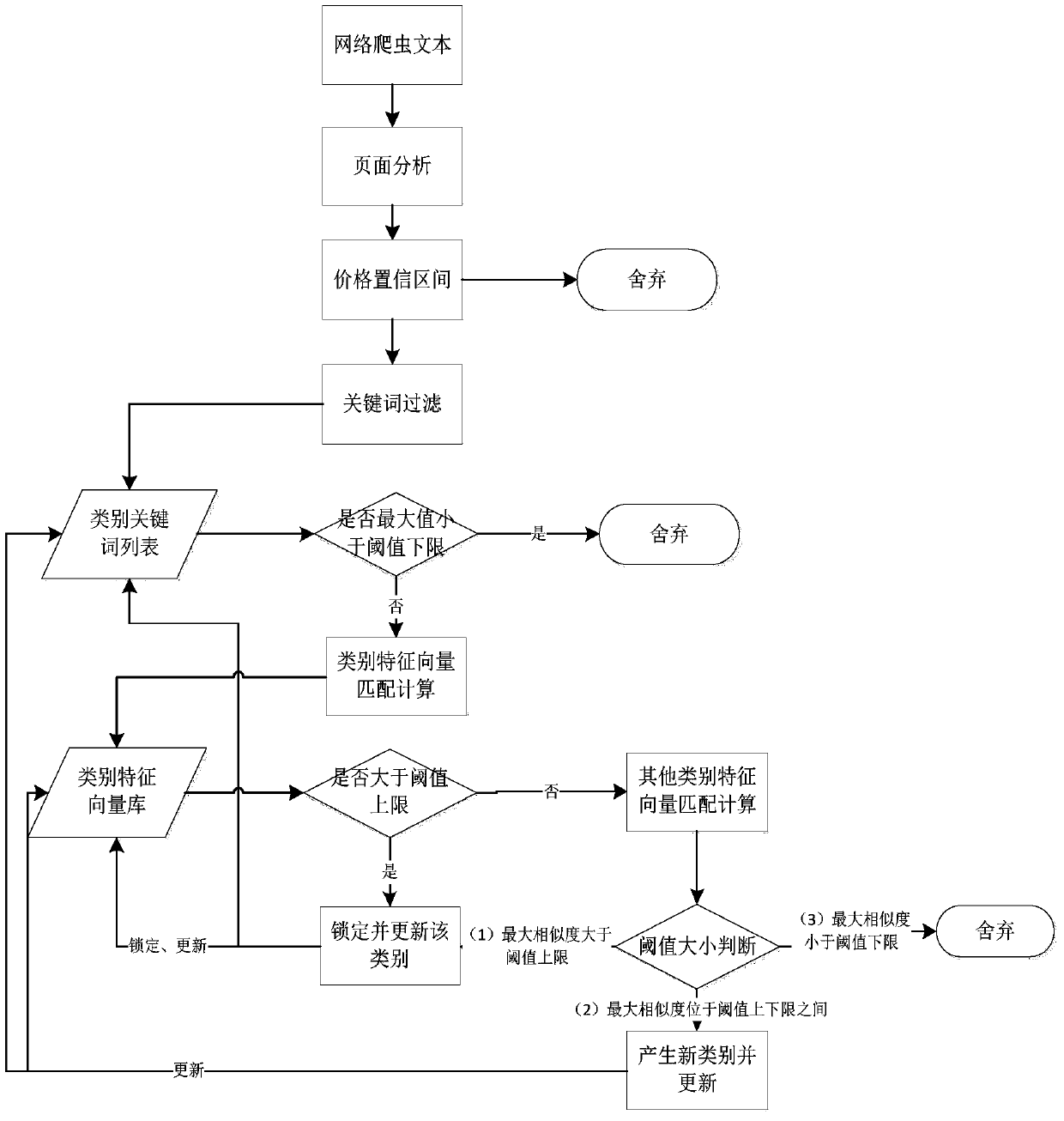

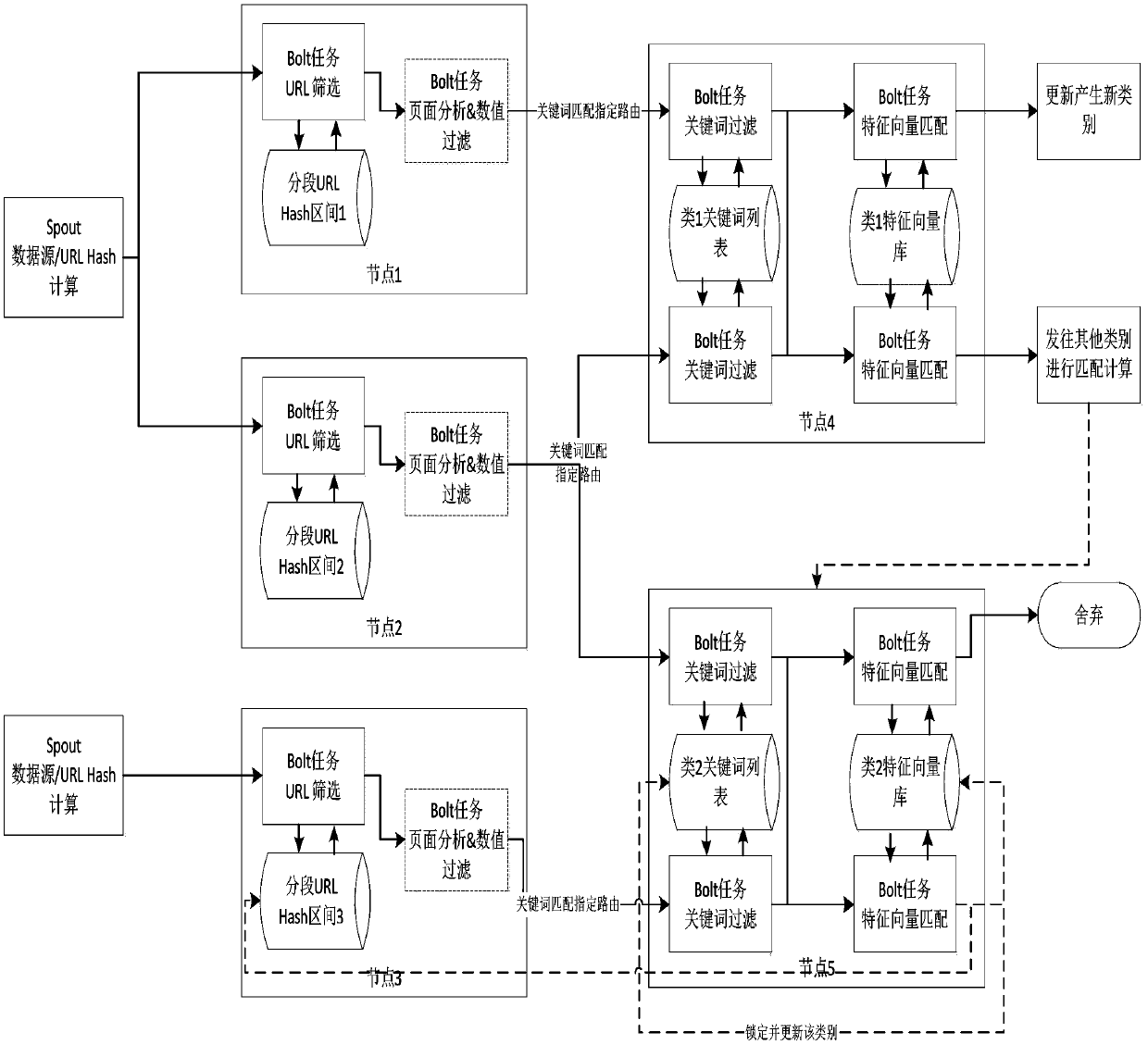

A method of crawling and screening financial warehouse receipt risk control information based on stream computing

ActiveCN106126642BAchieve decouplingPrevent affecting processing efficiencyWeb data indexingSpecial data processing applicationsRisk ControlData mining

The invention discloses a financial warehouse receipt risk-control information crawling and screening method based on stream-oriented computation. Based on a stream-oriented computation technology, a crawling process is decoupled into six sub-processes: URL screening, page analysis, keyword filtering, numerical value filtering, feature vector matching filtering, and resource update. Using the technical scheme can solve problems that a conventional method is relatively low in real-time property in parallel crawler aspect, and financial warehouse receipt risk-control is high in cargo assessment real-time property requirement.

Owner:BEIJING UNIV OF TECH

Wire crimping device for wire cutting machine

InactiveCN106270850BHigh strengthPrevent affecting processing efficiencyElectrical-based machining electrodesWire cuttingEngineering

The invention discloses a wire pressing device for a linear cutting machine tool. The linear cutting machine tool is provided with the wire pressing device on the other side, opposite to a workpiece, of an electrode wire; the wire pressing device comprises a box body, and a slide mechanism connected to the box body; a first cutting guide wheel and a second cutting wheel are respectively arranged at two ends of the side surface, opposite to the electrode wire, of the box body; the first cutting guide wheel is connected with the slide mechanism through a first fixed block; the second cutting guide wheel is connected with the box body through a second fixed block; wire pressing grooves for accommodating the electrode wire are respectively formed in one surfaces, opposite to the electrode wire, of the first fixed block and the second fixed block; and the two wire pressing grooves are respectively communicated with the first cutting guide wheel and the second cutting guide wheel. The wire pressing device can adjust the length of the electrode wire on a machining section, and horizontally moves to contact the electrode wire with the workpiece for machining, so that the electrode wire on the machining section is stable in strength, the deformation of the workpiece caused by looseness of the electrode wire in the machining process is prevented, and the machining precision is guaranteed.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com