Numerically-controlled machine tool with material guide channel

A technology of CNC machine tools and material guides, which is applied to the parts of grinding machine tools, grinding machines, manufacturing tools, etc. It can solve the problems of workpiece collision, inconvenient positioning of workpiece blanks, wear and other problems, and achieve the effect of preventing wear and smooth conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

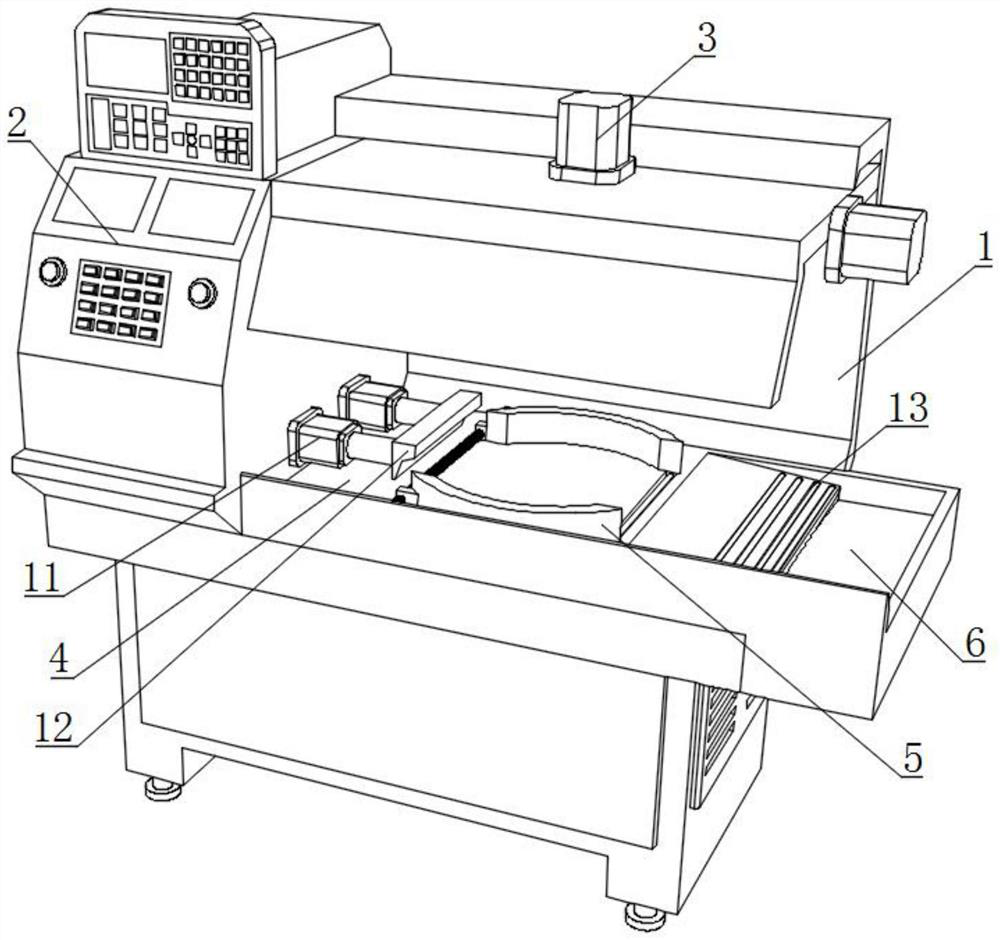

[0029] like Figure 1-6 As shown, the present invention provides a CNC machine tool with a material guide, including a CNC machine tool main body 1, the CNC machine tool main body 1 is composed of a control device 2, a grinding mechanism 3 and an operating table 4, and the right bottom end of the control device 2 is connected to the The left side of the operating table 4 is connected by welding, the grinding mechanism 3 is arranged above the operating table 4, the upper surface of the operating table 4 is provided with a positioning mechanism 5, and the right side of the operating table 4 is welded with a material guide 13, which guides the A receiving mechanism 6 is fixedly installed on the right side of the material channel 13. The receiving mechanism 6 includes a material receiving box 61 and a load-relief assembly 62. The load-relief assembly 62 includes a pressure-resistant elastic sleeve 621. An elastic receiving strip 624 and a pressure releasing elastic bag 625 are arr...

Embodiment 2

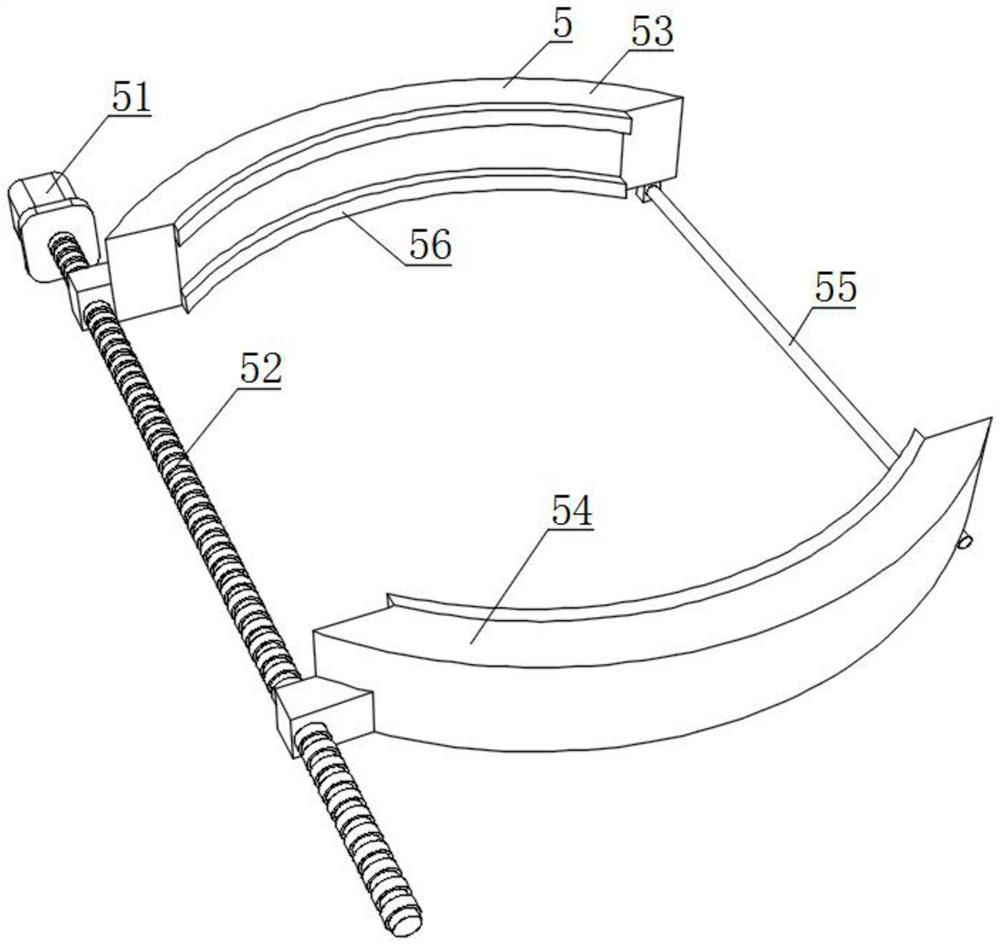

[0033] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the positioning mechanism 5 includes a motor 51 and a threaded rod 52, the front of the motor 51 is fixedly connected to the back of the console 4, and the The output shaft is fixedly connected with one end of the threaded rod 52, and the other end of the threaded rod 52 is rotatably connected with the inner wall of the console 4. The outer surface of the threaded rod 52 is threadedly sleeved with a clamp seat 1 53 and a clamp seat 2 54. The clamp seat 1 53. The inside of the second clamp seat 54 is respectively provided with a positive thread and a reverse thread that are adapted to the outer surface of the threaded rod 52, and the inner arc surfaces of the first clamp seat 53 and the second clamp seat 54 are fixedly connected with soft extrusion bushings 56. The inner wall of the bottom surface of one end of the clamp seat 53 and the clamp seat 2 5...

Embodiment 3

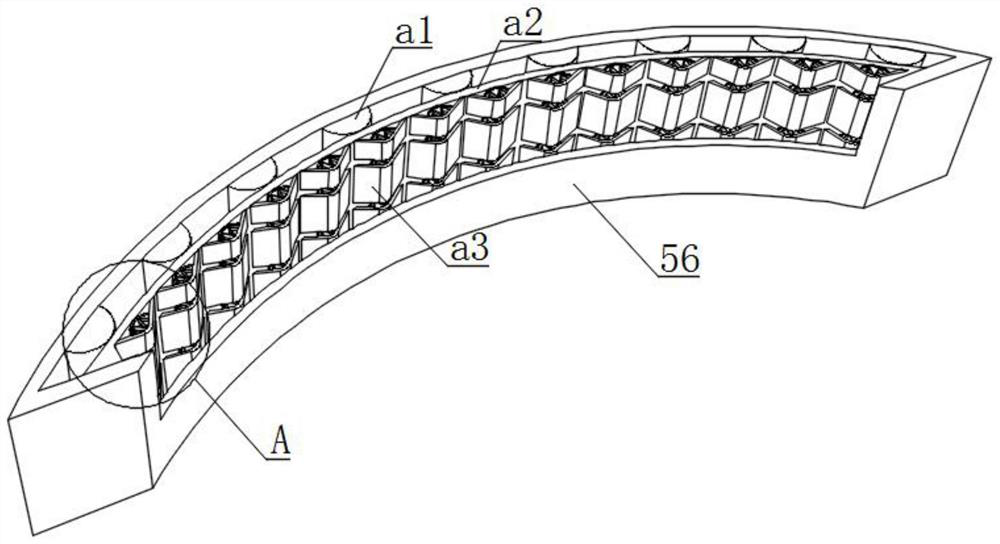

[0035] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, micro-elastic rubber pads a1 are fixedly installed on the inner surface of the soft extrusion sleeve 56, and the micro-elastic rubber pads a1 are equally spaced. On the inner surface of the soft extrusion sleeve pad 56, the outer surface of the micro-elastic rubber pad a1 is fixedly connected with a soft curved surface pressure plate a2, and the two ends of the soft curved surface pressure plate a2 are connected with the soft extrusion sleeve cushion 56. The inner surface is fixedly connected, an elastic flap a3 is fixedly installed on the outer surface of the soft arc pressure plate a2, the outer surface of the elastic flap a3 is fixedly connected with the inner surface of the soft extrusion sleeve 56, and the inner side of the elastic flap a3 is fixedly connected. The surface is fixedly connected with an elastic limiting aligning plate a5, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com