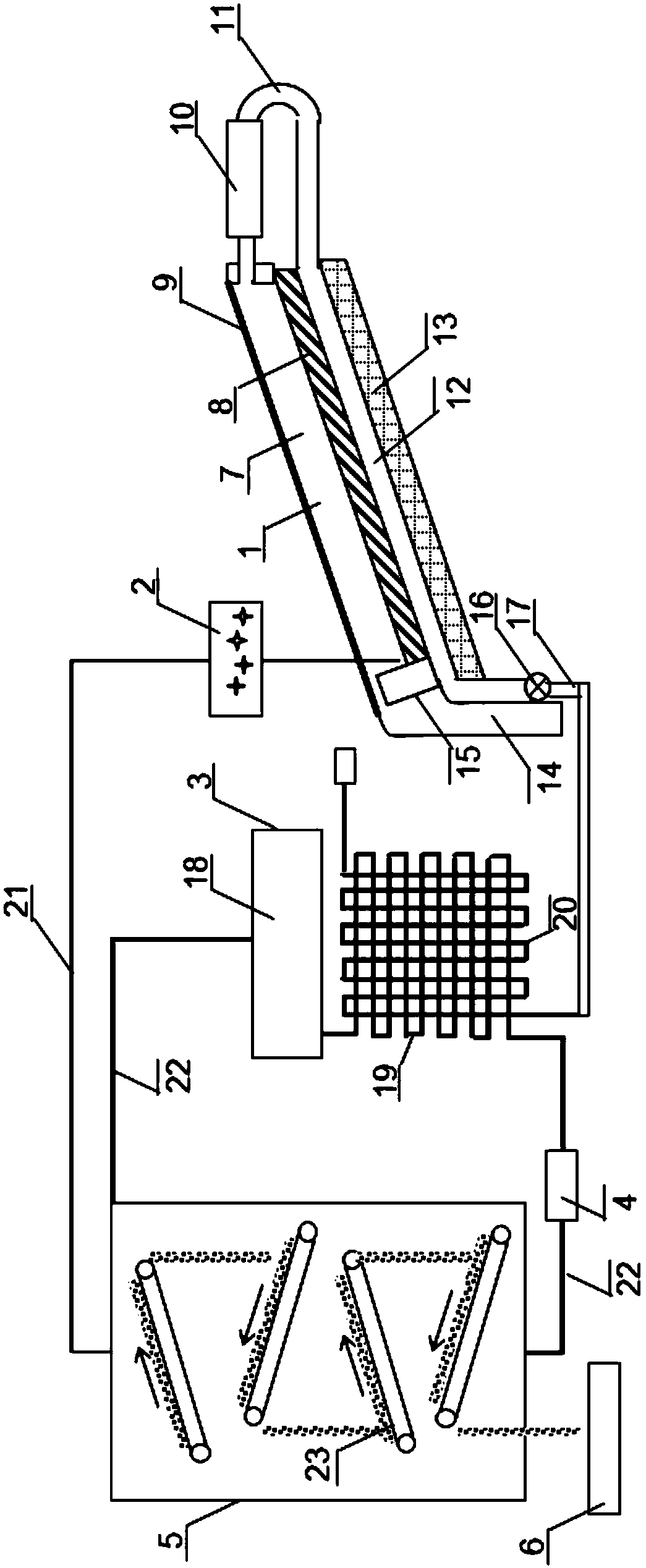

Sludge drying comprehensive treatment system

A comprehensive treatment and sludge drying technology, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, and temperature-controlled sludge treatment, etc. It can solve the problems of high water content of sludge and expensive outsourcing treatment. , to achieve the effect of high efficiency, low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A sewage treatment plant in a city in Zhejiang Province produces 10 tons of sludge a day, 3,650 tons a year, and the outsourcing treatment fee per ton is 3,700 yuan, and the outsourcing fee for one year is 13.505 million yuan. At the same time, two people need to be hired to carry out Caretaker, the salary is 180,000 yuan a year, and the total annual sludge treatment cost is 13.685 million yuan.

[0031] After using this system, the moisture content of the sludge is controlled below 40%, 1,460 tons of sludge are produced a year, the annual outsourcing cost is 5.402 million yuan, and the total annual other costs are 150,000 yuan. The total annual sludge treatment cost is 555.2 ten thousand yuan. The new sludge dewatering and drying equipment for this system has a total investment of 750,000 yuan, saving 7.383 million yuan in the first year and 8.133 million yuan per year from the second year onwards.

Embodiment 2

[0032] Example 2: A domestic sewage treatment station in a residential area in Jiangsu produces 0.5 tons of sludge a day and 182.5 tons a year. The outsourcing treatment fee per ton is 3,200 yuan, and the outsourcing fee for a year is 584,000 yuan. At the same time, one Part-time staff, the salary is 50,000 yuan a year, and the total annual sludge treatment cost is 634,000 yuan.

[0033] After using this system, the moisture content of the sludge is controlled below 40%, 73 tons of sludge are produced a year, the annual outsourcing cost is 233,600 yuan, and the total annual other costs are 20,000 yuan. The total annual sludge treatment cost is 25.36 ten thousand yuan. The new sludge dewatering and drying equipment for this system has a total investment of 200,000 yuan, saving 180,400 yuan in the first year and 380,400 yuan a year in the second year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com