Assembly type crushing roller and wood pulp crusher

A pulverizing roller and pulverizer technology, which is applied in the field of sanitary equipment, can solve the problems of accelerated wear of dull knives, and achieve the effects of uniform wear, convenient replacement, and quick disassembly and connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

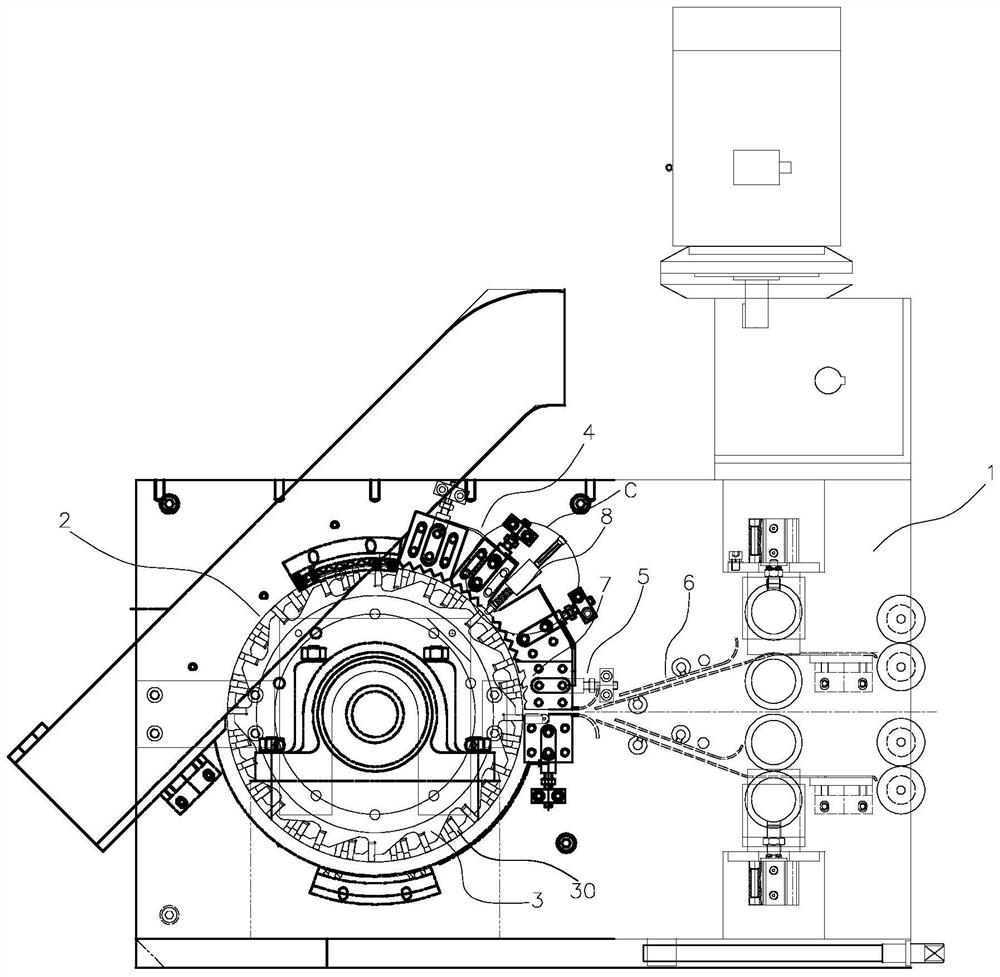

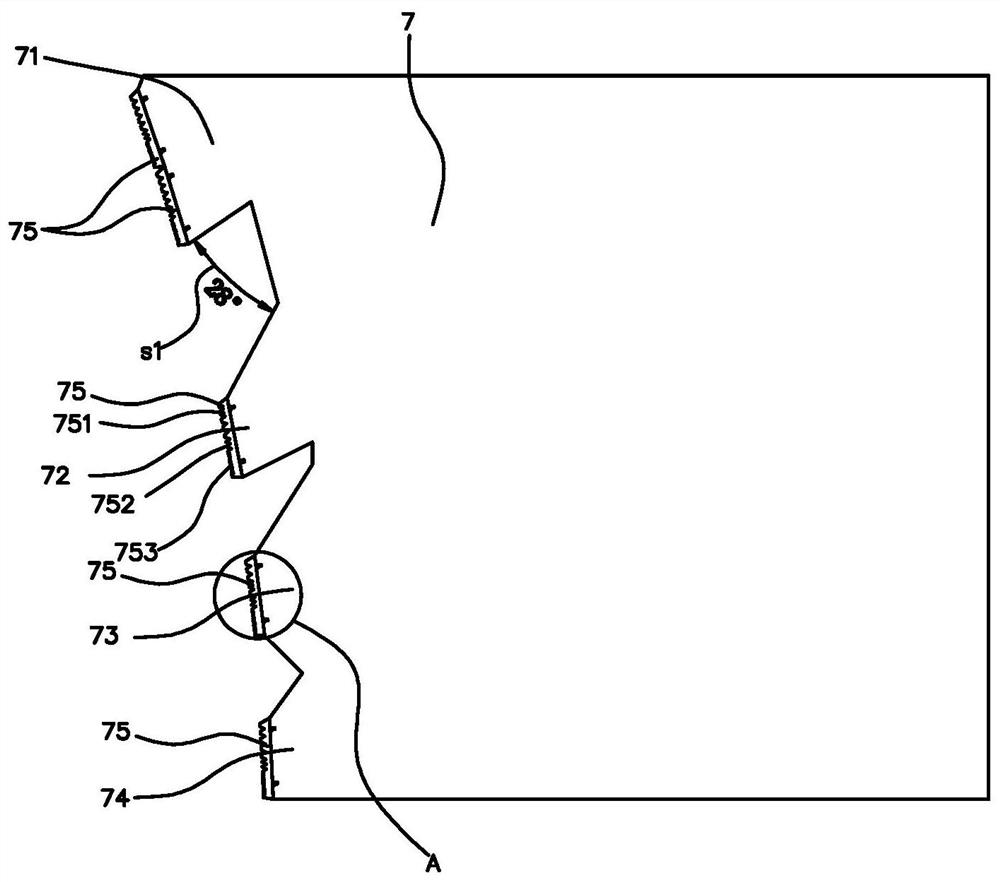

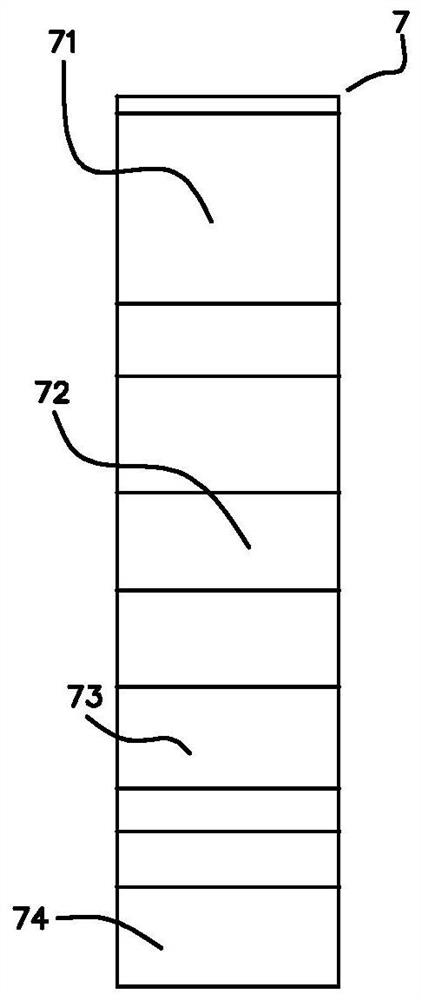

[0039] refer to Figure 1 to Figure 11 , the present embodiment provides an assembled pulverizing roller and a wood pulp pulverizer, comprising a frame 1, a pulverizing mechanism 2 arranged on the frame 1, a pulverizing roller 3 arranged in the pulverizing mechanism 2, and a The upper knife-edge plate assembly 4, the lower knife-edge plate assembly 5 arranged on one lateral side of the crushing mechanism 2, and the input production line 6 arranged on the frame 1, the lower knife-edge plate assembly 5 is detachably provided with a knife-edge plate 7, The input production line 6 imports the wood pulp from the input production line 6, and then enters the crushing mechanism 2 through the lower knife-edge plate assembly 5, and the crushing roller 3 in the crushing mechanism 2 rotates to cooperate with the upper knife-edge plate assembly 4 and the lower kn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com