Plastic pipe cutting device

A cutting device and pipe-use technology, which is applied in the field of plastic pipe processing, can solve the problems of a large proportion of users, polluted gas by flame cutting, and high cost, and achieve the effects of wide application range, uniform incision, and prevention of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

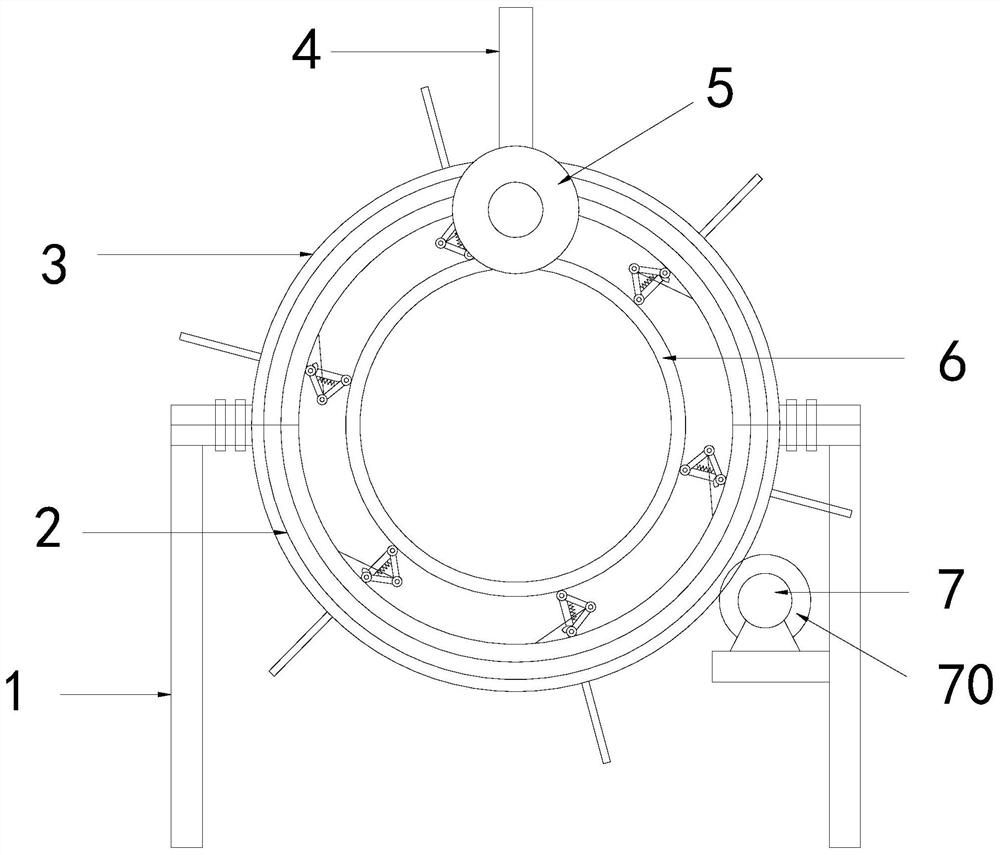

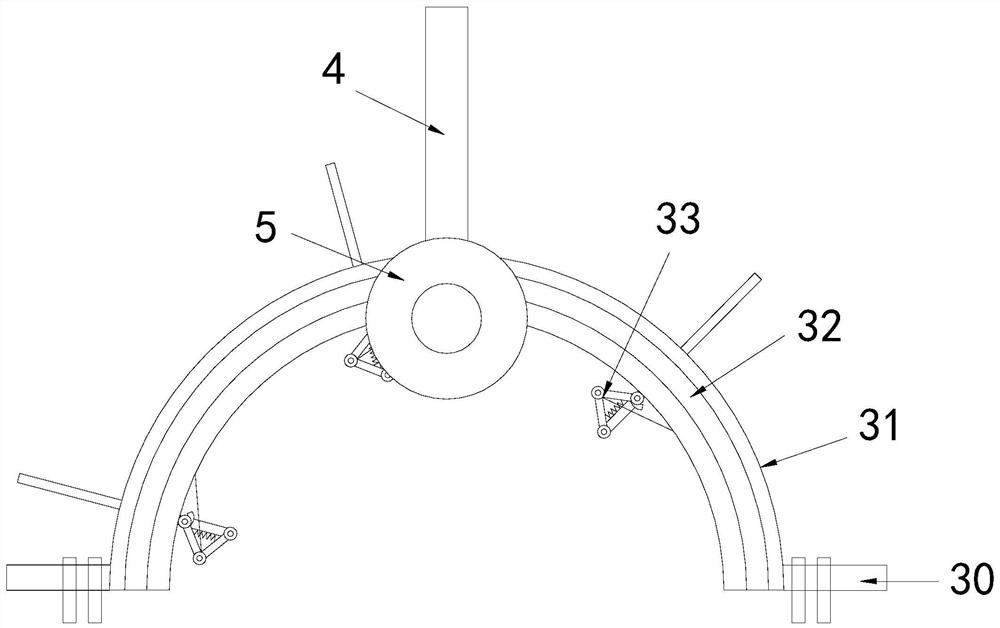

[0027] see Figure 1-2 , the present invention provides a technical solution for a plastic pipe cutting device: its structure includes a column 1, a lower fixing device 2, an upper fixing device 3, a telescopic rod 4, a cutting machine 5, a pipe body 6, and a motor 7, the lower fixing device 2 Two sides are respectively connected with uprights 1, the lower fixing device 2 and the upper fixing device 3 are connected by bolts, the upper fixing device 3 is installed with a telescopic rod 4, and the bottom of the telescopic rod 4 is connected with the cutting machine 5, so The motor 7 is arranged below the lower fixing device 2 and is connected to the side of the column 1. The upper fixing device 3 includes a support plate 30, a semicircular body 31, a half toothed ring 32, and a fixing structure 33, and the two ends of the semicircular body 31 are connected respectively. There is a support plate 30, one side of the semi-circular body 31 is provided with a chute, the chute is prov...

Embodiment 2

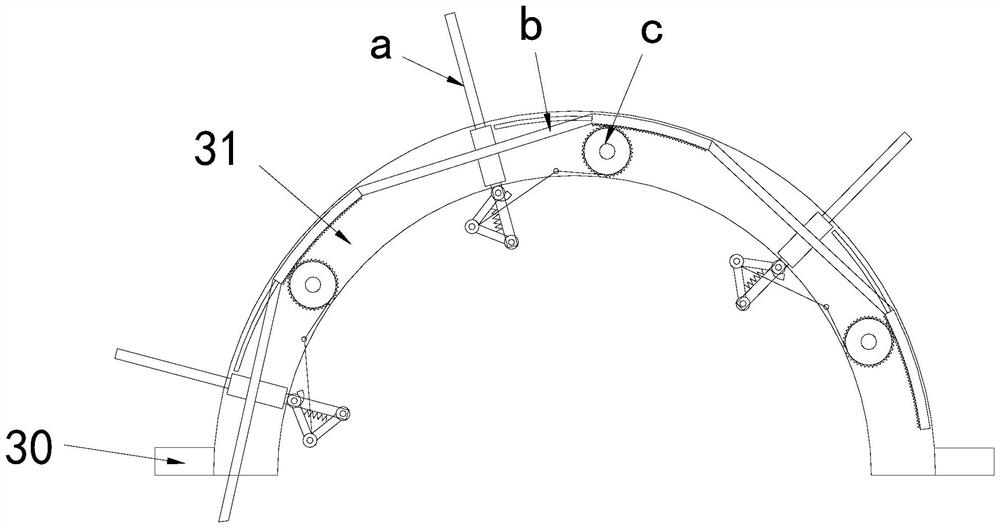

[0030] see Figure 1-4 , the present invention provides a technical solution for a plastic pipe cutting device: the fixing structure 33 includes a guide structure a, a support rod b, and a winding structure c, and the guide structure a and the winding structure c are installed on the semicircular body 31. , the winding structure c is connected with the support rod b, the guide structure a includes a guide rod a1, a guide sleeve a2, two connecting rods a3, a spring a4, the guide sleeve a2 is connected to the semicircular body 31, the The guide sleeve a2 is penetrated by the guide rod a1, one end of the two connecting rods a3 is hinged on the inside of the semicircular body 31, and the other end is hinged with the guide rod a1, the two connecting rods a3 are provided with a spring a4, and the winding structure c includes The pulling rope c1, the winding wheel c2, the rack c3, and the guide groove c4, the guide groove c4 is provided on the semicircular body 31, the guide groove c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com