A winding forming control method for real-time detection and dynamic tension adjustment

A technology of dynamic adjustment and real-time detection, applied in the directions of transportation and packaging, thin material handling, conveying filamentous materials, etc., can solve the problems of insufficient yarn traction, yarn breakage, sagging, etc., to avoid overshoot problems, improve Stability, the effect of reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing.

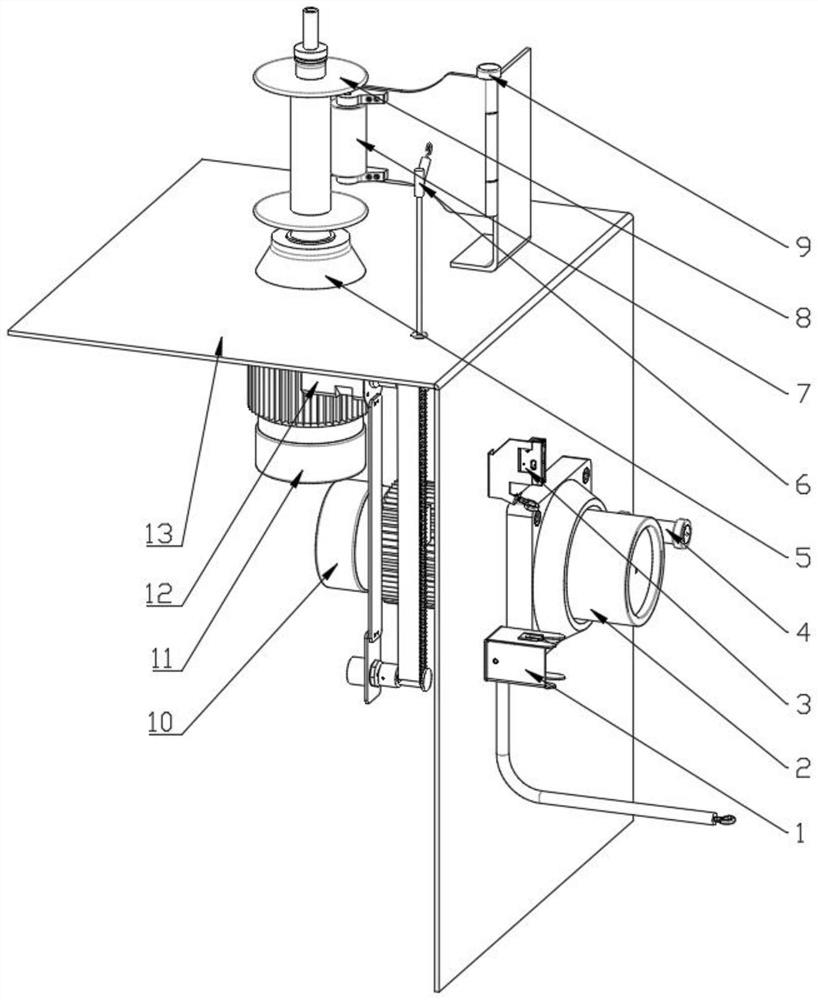

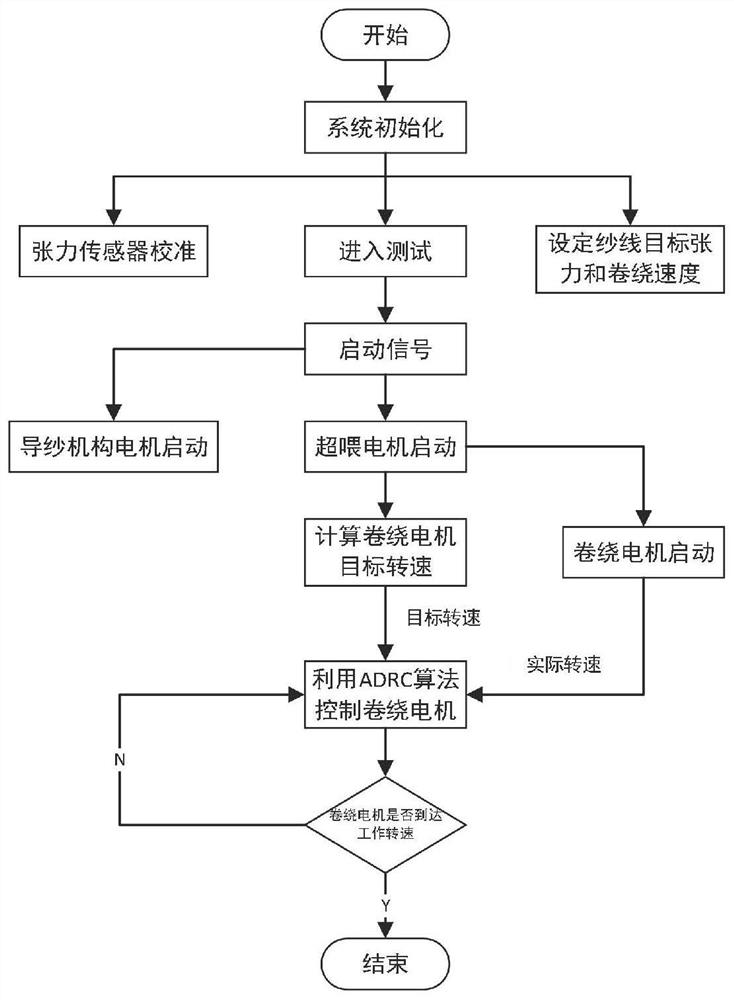

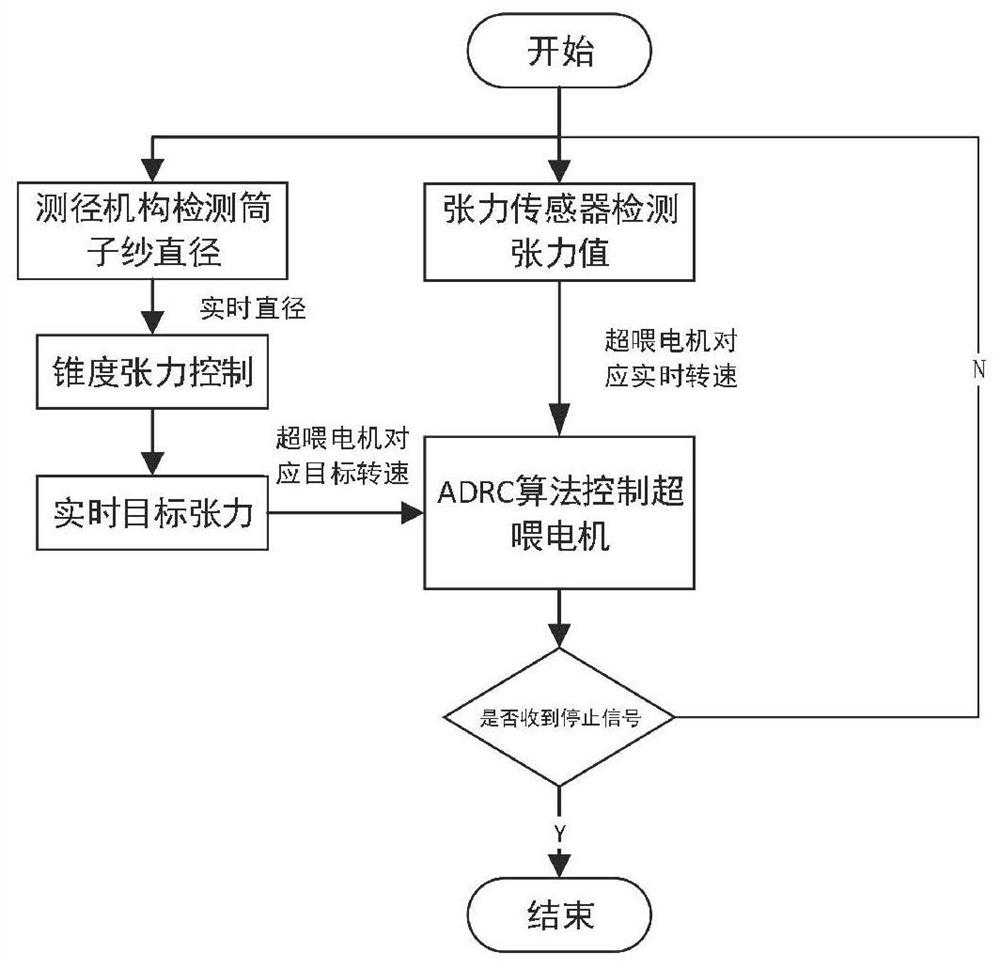

[0061] Such as figure 1 As shown, a winding forming control method for real-time detection and dynamic adjustment of yarn tension adopts a yarn winding forming device, which includes a circuit control board (not shown), a fixed yarn guide mechanism 1, a super Feeding mechanism 2, tension sensor 3, winding rod 4, winding mechanism 5, dynamic yarn guiding mechanism 6, diameter measuring mechanism 7, yarn core 8 and frame 13.

[0062] The frame 13 is a box, and its side and top are provided with through holes and threaded holes for installing other mechanisms. Winding mechanism 5 is installed on the top of frame 13, comprises winding motor 11 and winding shaft. The winding motor 11 is fixed in the frame 13, and the output shaft is arranged upwards, and is fixed with the vertical winding shaft. A yarn core 8 is sleeved and fixed around the reel.

[0063] The diameter measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com