Construction process for removing skirting line of wood floor

A construction technique and technology for wooden floors, applied in the field of construction techniques for removing skirtings from wooden floors, can solve problems such as difficulty in finishing edges and leveling, and achieve the effects of physical property protection, simple construction method, and easy operation of construction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

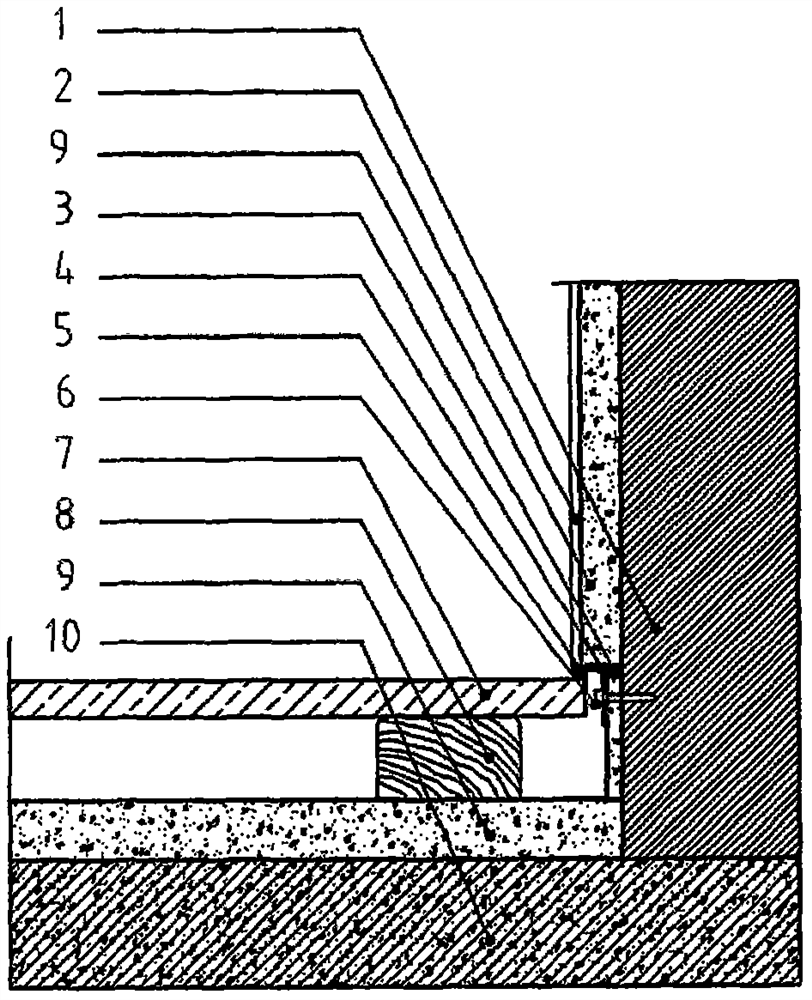

[0040] The construction process of removing the skirting line of the wooden floor includes the construction process of plastering the wall surface with cement mortar and the construction process of plastering the wall surface without cement mortar.

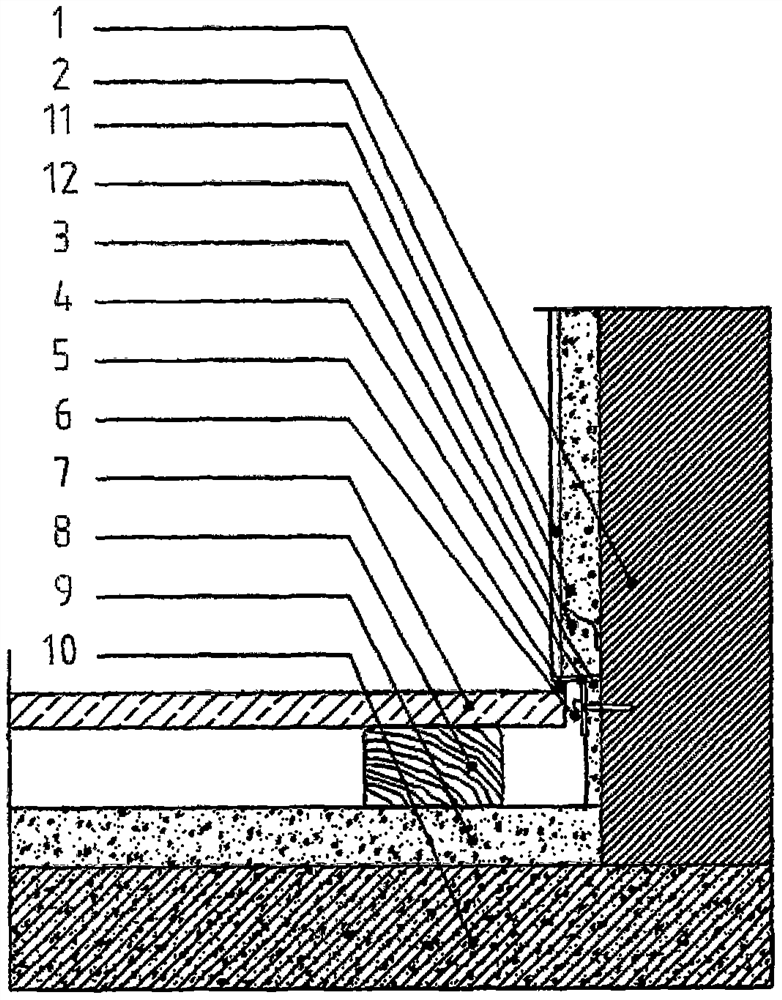

[0041] Such as figure 1 As shown, the operation method of the construction process of cement mortar plastering the wall is as follows:

[0042] (1) Draw the design height line of the 7 layers of the wooden floor on the corresponding wall 1;

[0043] (2) Draw another parallel line 30-50mm above the height line of the surface layer;

[0044] (3) Chisel the wall 1 below the height line to a depth of 20-25mm;

[0045] (4) Use cement mortar or waterproof putty to scrape the chiseled wall surface 1 batch level, and the horizontal distance between the scraped surface and the original wall surface 1 is 15-20mm;

[0046] (5) Draw the design height line of the 7 surface layers of the wooden floor on this surface layer;

[0047] (6) Draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com