Full-automatic appearance inspection box placing and packaging equipment for electrolytic capacitors

An electrolytic capacitor, visual inspection technology, applied in transportation and packaging, measuring devices, instruments, etc., can solve the problems of large demand for workers, quality risks and hidden dangers, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

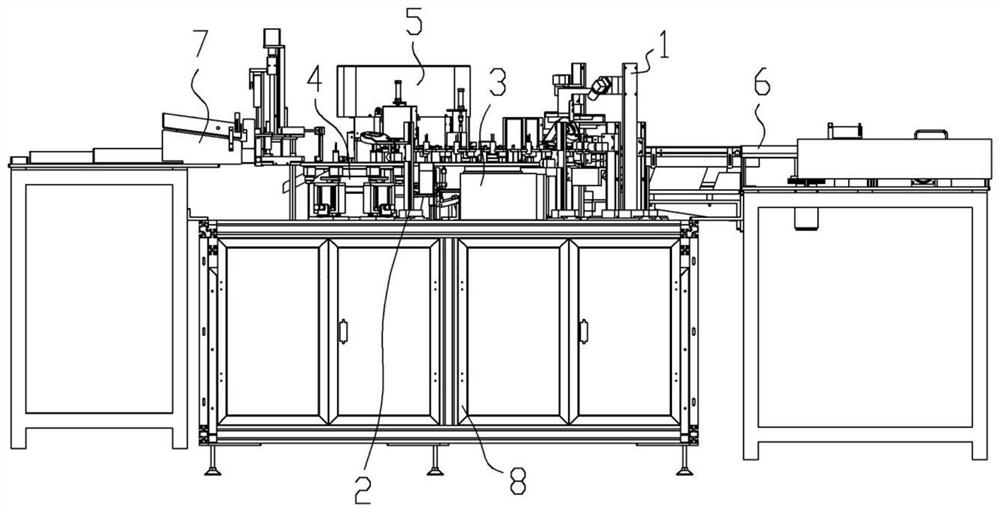

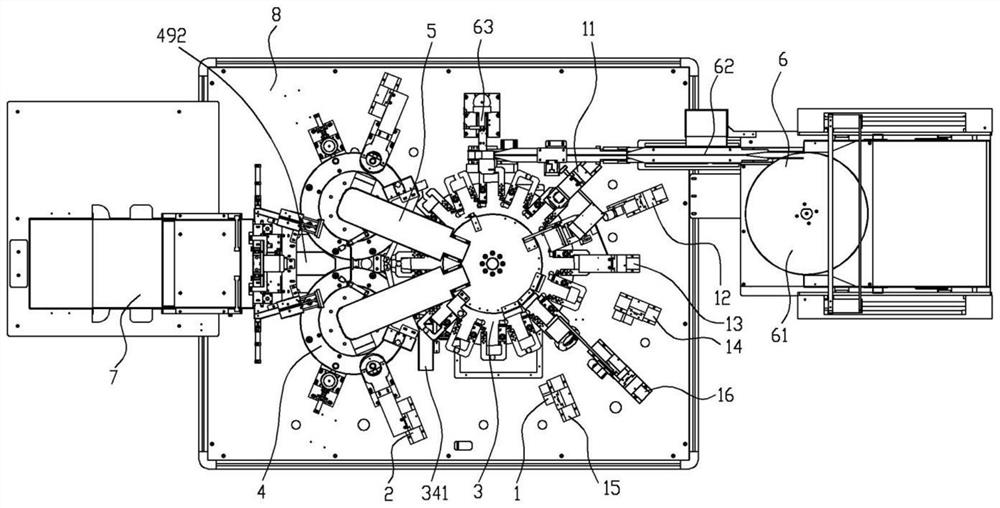

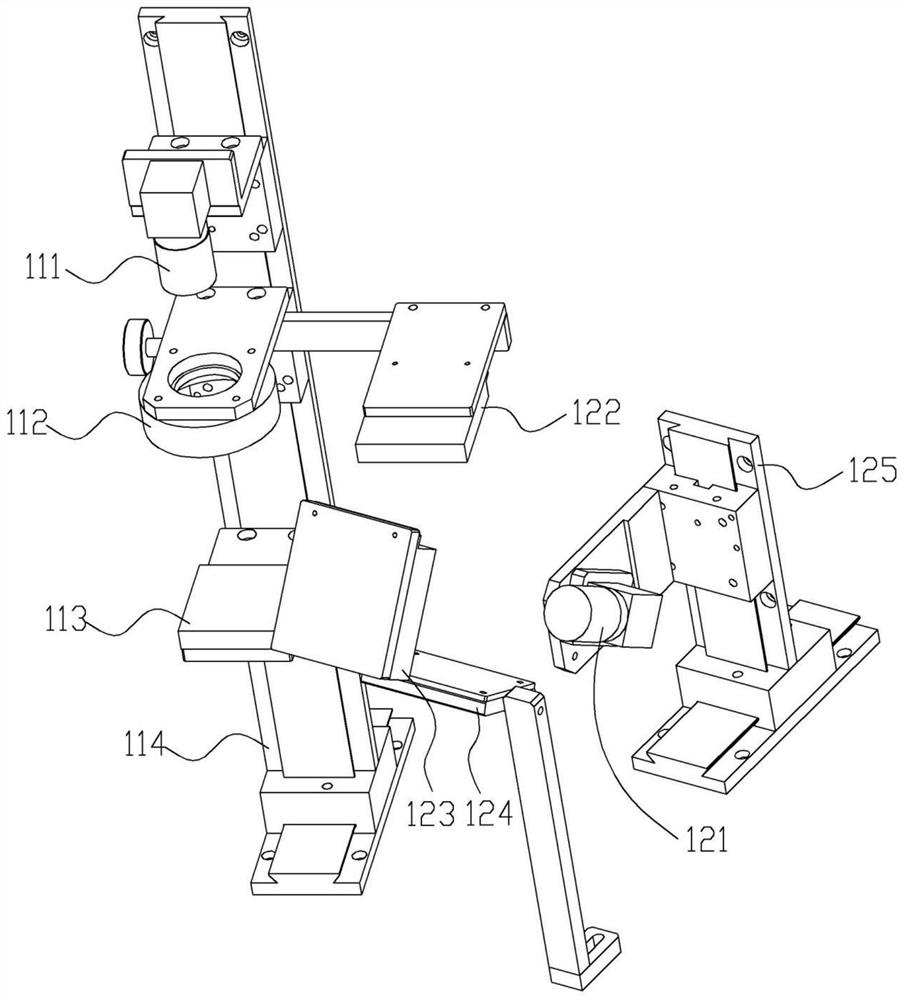

[0033] refer to Figure 1 to Figure 14 , a kind of electrolytic capacitor full-automatic visual inspection pendulum packing equipment of the present invention, comprises visual inspection mechanism 1, material mixing inspection mechanism 2, first transfer disc 3, second transfer disc 4, translation mechanism 5, feeding mechanism 6. Automatic box swing mechanism 7 and frame 8.

[0034] The first transfer disc 3 comprises a transfer disc precision divider 31, a first turntable 32 and a transfer clamp 33, the transfer clamp 33 is a plurality, and the transfer disc precision divider 31 is fixedly installed on the frame 8 by bolts, and the transfer circle The disc precision divider 31 is driven to rotate by the motor, and the first turntable 32 is installed on the transfer disc precision divider 31, so that the transfer disc precision divider 31 can drive the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com