Method for suppressing stimulated Raman scattering, high-power fiber laser and all-solid-state microstructured fiber

A technology of stimulated Raman scattering and microstructured fiber, which is applied in the structure/shape of active medium, laser, laser components, etc., and can solve the problem of optical fiber multi-mode operation output beam quality degradation, unfavorable practical application, transmission loss and bending Sensitivity issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

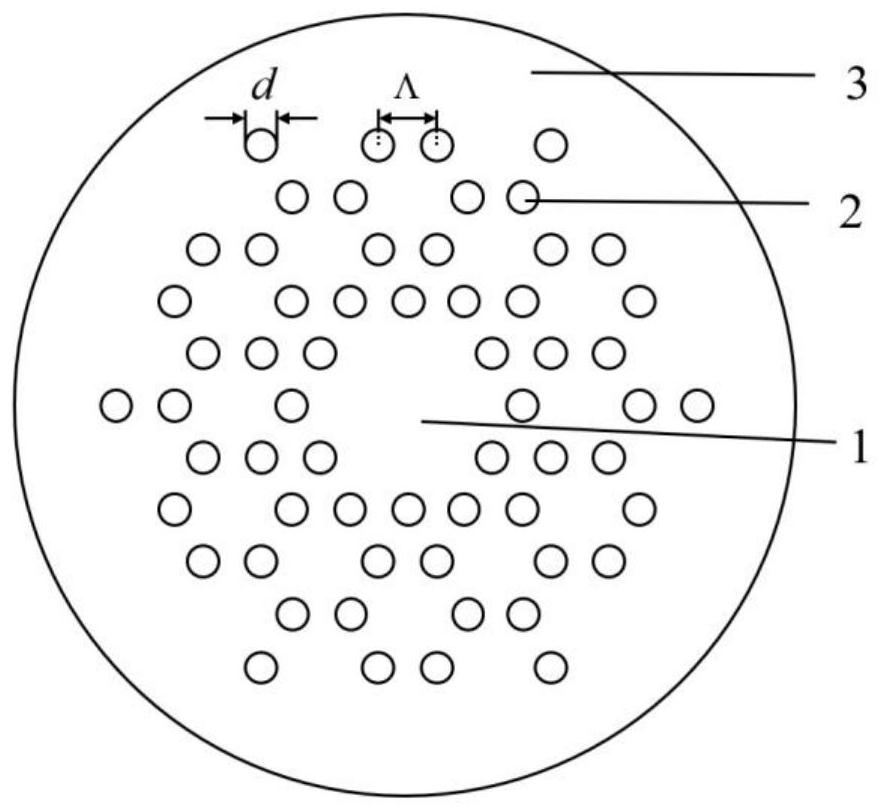

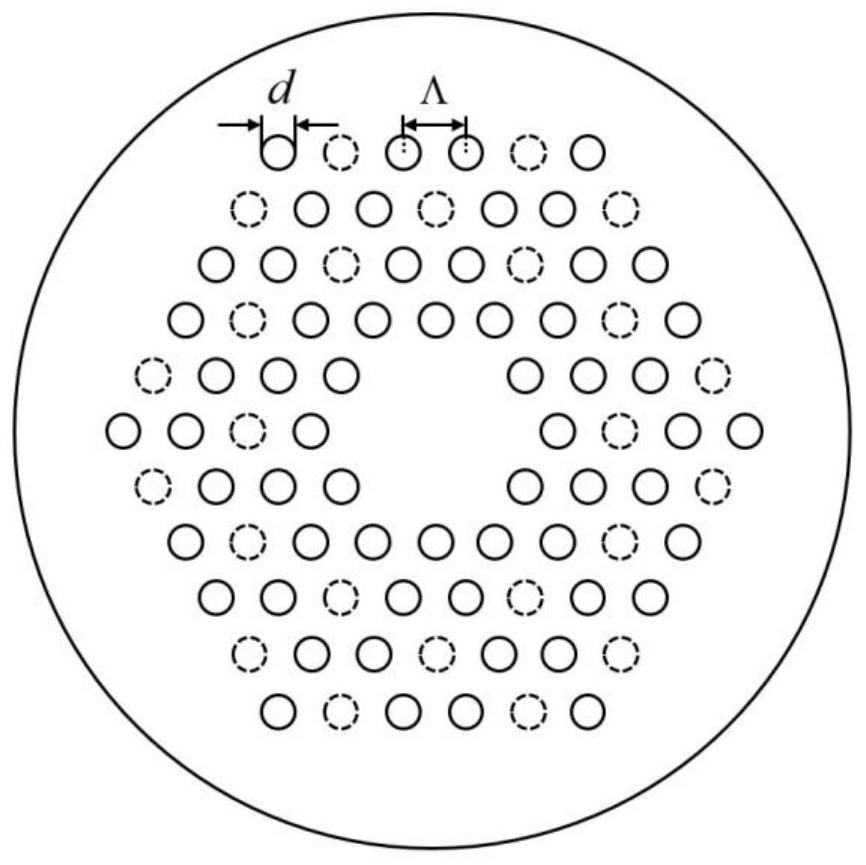

[0045] The structure of the all-solid-state microstructure optical fiber provided in an embodiment of the present invention is as follows: figure 1 As shown, its parameters include: the diameter d of the germanium rod is 4.8 μm, the center distance Λ of any two adjacent points in the regular hexagonal lattice is 12 μm, and the fiber characteristic parameters is 0.4, and the core diameter 4Λ-d is 43.2 μm. The fiber core is formed by 7 quartz rods arranged closely in a periodical manner.

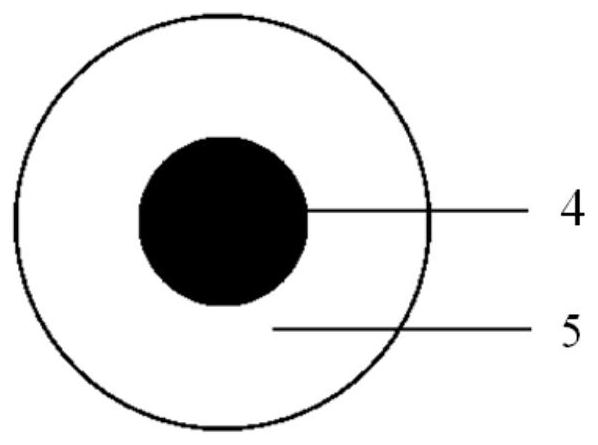

[0046] The schematic diagram of the cross-sectional structure of the germanium rod used in this embodiment is as follows: image 3 As shown, the germanium rod 2 includes a high-refractive-index germanium-doped region 4 located in the center and a low-refractive-index cladding region 5 located in the outer layer, wherein the refractive index of the high-refractive-index germanium-doped region 4 is a parabolic graded index distribution, such as Figure 4 shown. The outer low-refractive-index...

Embodiment 2

[0054] The structure of the all-solid-state microstructure optical fiber provided in an embodiment of the present invention is as follows: figure 1 As shown, its parameters include: the diameter d of the germanium rod is 5.3 μm, the center distance Λ of any two adjacent points in the regular hexagonal lattice is 13.95 μm, and the characteristic parameters of the fiber are is 0.38, and the core diameter 4Λ-d is 50.5 μm. The fiber core is formed by 7 quartz rods arranged closely in a periodical manner.

[0055] Specifically, the schematic diagrams of the cross-sectional structure and refractive index distribution of the germanium rod used in this embodiment are respectively as follows image 3 and Figure 9 As shown, the germanium rod 2 includes a high-refractive-index germanium-doped region 4 in the center and a low-refractive-index cladding region 5 in the outer layer, wherein the high-refractive index germanium-doped region 4 has a parabolic graded index distribution. The...

Embodiment 3

[0061] This embodiment provides a method for suppressing stimulated Raman scattering, including:

[0062] Design an all-solid-state microstructured fiber, where the structure of the all-solid-state microstructured fiber is as follows figure 1 As shown, it includes a core and a microstructure cladding, the core is a solid core, the microstructure cladding is clad on the periphery of the core, and the microstructure cladding includes germanium rods located in a regular hexagonal lattice and a solid substrate, the regular hexagonal lattice is distributed with multiple layers from the inside out, the center distance Λ of any two adjacent points in the regular hexagonal lattice is equal, the core is located at the center of the regular hexagonal lattice, and many germanium The rods are arranged in a sparse structure on each layer of regular hexagonal lattice, and a solid substrate is filled between the germanium rods. Specifically, the regular hexagonal lattice has four layers, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com