Direct-current power supply system lead-acid storage battery pack discharge test system and method

A DC power system, lead-acid battery technology, applied in battery circuit devices, system integration technology, battery load switching, etc., can solve problems such as high working environment temperature, non-environmental protection, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

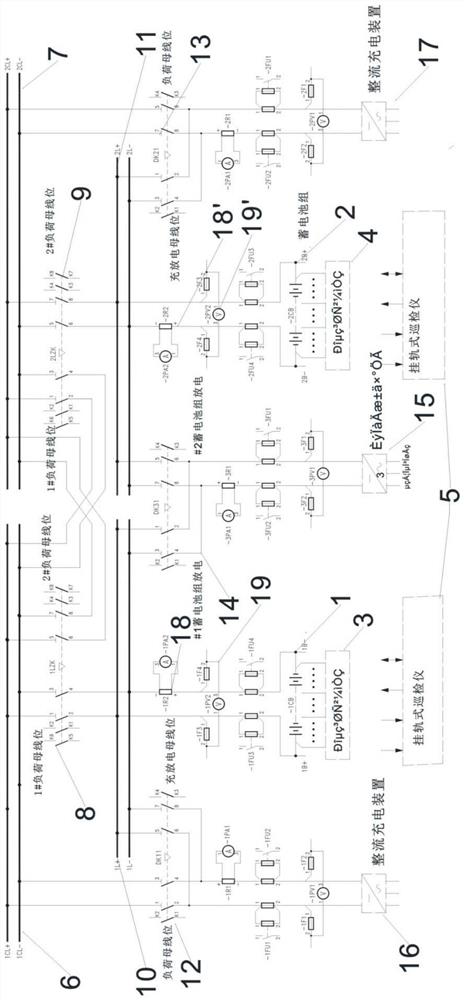

[0025] Such as figure 1 As shown, a discharge test system for a lead-acid battery pack in a DC power supply system, the system includes:

[0026] #1 lead-acid battery group 1, #2 lead-acid battery group 2;

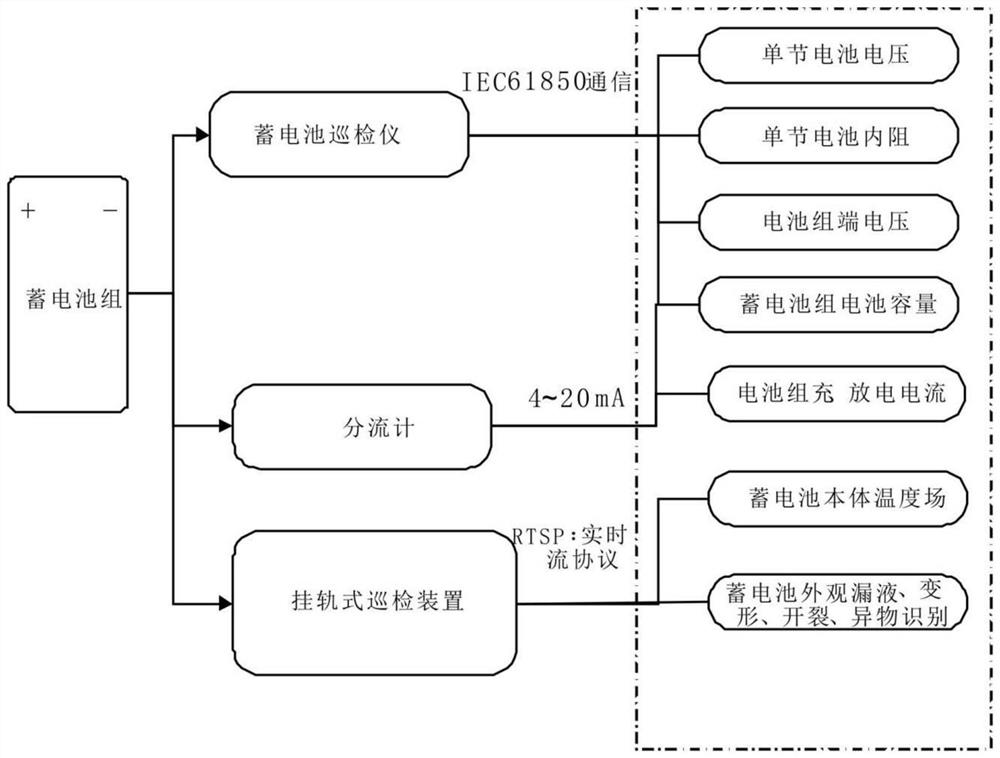

[0027] The first DC load bus 6 and the first charging and discharging bus 10 are connected to the first rectifying and charging device 16 through the first switch 12; the first charging and discharging bus 10 is connected to #1 lead-acid storage battery group 1; #1 lead-acid storage battery group 1 Connect the first battery inspection instrument 3, the first battery inspection instrument 3 is used for real-time measurement of the single-cell voltage and single-cell internal resistance of #1 lead-acid battery pack 1;

[0028] A first shunt meter 18 and a first voltage collector 19 are arranged on the connecting line between the first charge-discharge bus bar 10 and the #1 lead-acid battery group 1, and the first shunt meter 18 is used to measure the voltage of the #1 lead-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com