Wind power converter control method, power equipment control device and converter

A technology of wind power converter and control method, which is applied in wind power generation, output power conversion device, AC power input conversion to AC power output, etc., which can solve the problem of polluting the power grid, increase the volume of the converter, and increase the number of converters Cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

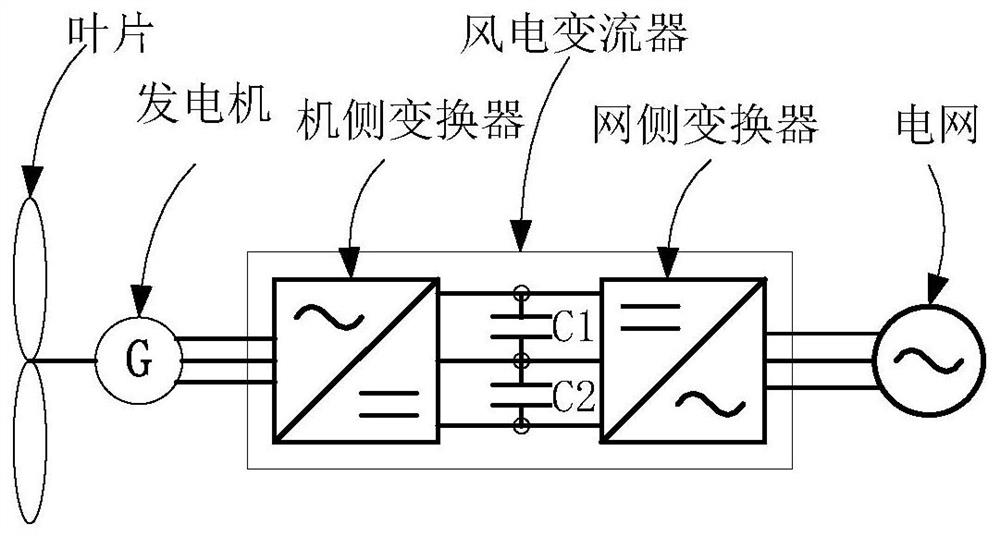

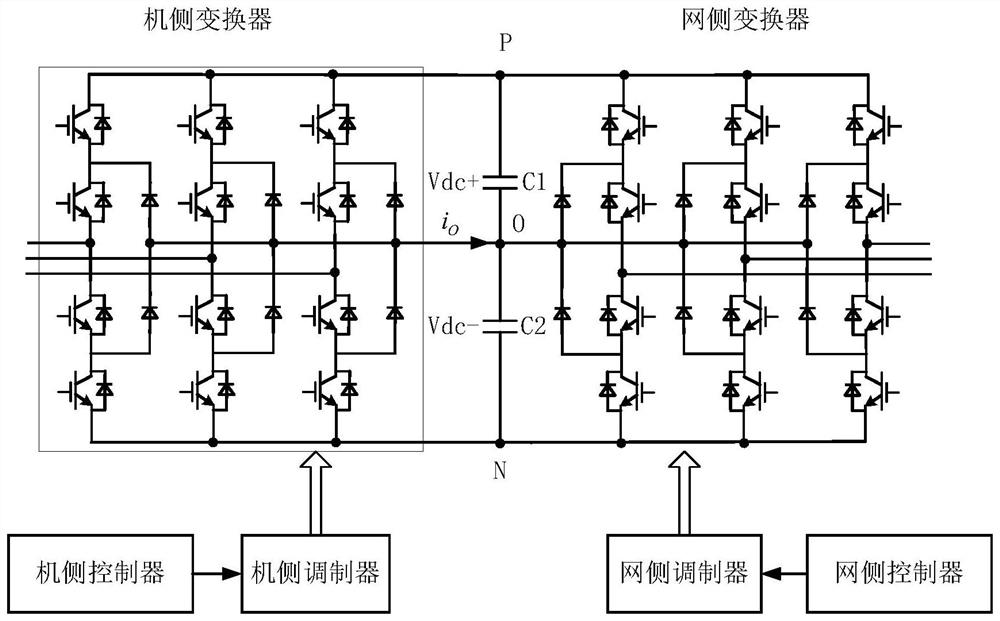

[0022] see figure 1 and figure 2 , figure 1 It is the overall structural diagram of the wind power converter of the present invention; figure 2 It is a structural diagram of a wind power converter and its controller and modulator of the present invention; this embodiment discloses a control method for a wind power converter, and provides a wind power converter, the wind power converter includes a grid-side converter, A generator-side converter, a grid-side controller, and a generator-side controller, the grid-side controller controls the grid-side converter to transmit waves with three-level unipolarity, and the generator-side controller controls the generator-side converter The device adopts three-level bipolar wave transmission.

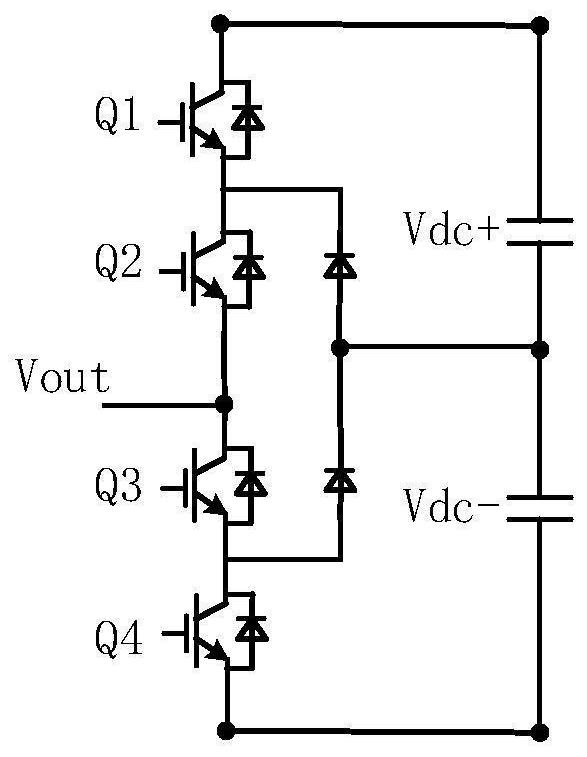

[0023] see Figure 3 to Figure 5 , image 3 It is the structural diagram of the three-level power tube of the wind power converter of the present invention; Figure 4 It is a structural diagram of the wind power converter modulator of the p...

Embodiment 2

[0027] In order to improve the bus voltage utilization ratio, the corresponding third harmonic can be injected into the grid-side reference voltage or the machine-side three-phase reference voltage in Embodiment 1. A typical injection method is assuming that the three-phase original reference voltages are respectively Vrefa ', Vrefb', Vrefc', the injected third harmonic is Vz=-0.5*max(Vrefa, Vrefb, Vrefc)-0.5*min(Vrefa, Vrefb, Vrefc), where max and min represent the maximum and minimum value, the final three-phase reference voltage is Vrefa=Vrefa'+Vz, Vrefb=Vrefb'+Vz, Vrefc=Vrefc'+Vz.

[0028] It is also possible to inject components for other purposes into the three-phase reference voltage, or to adjust the reference voltage according to other needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com