PCB metallization half-hole processing technology

A metallized semi-hole and processing technology, which is applied in the direction of the electrical connection of printed components, can solve the problems of extrusion and drawing, and can not be completely removed, so as to improve the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

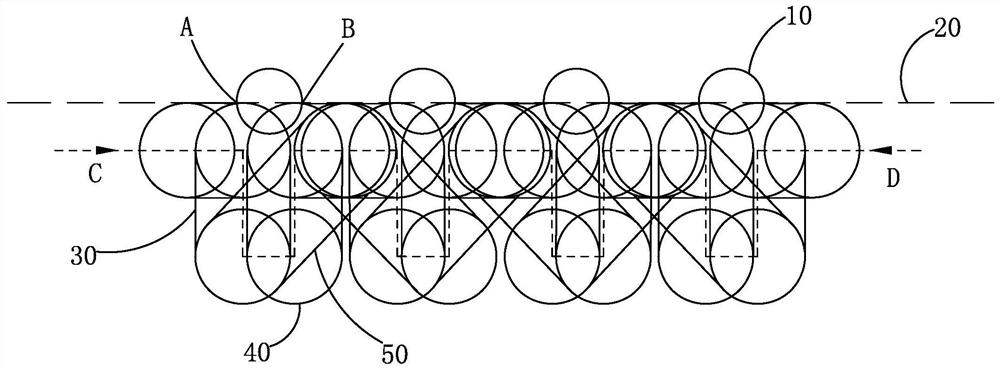

[0019] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the present invention provides a kind of PCB metallization half hole processing technology, is used for processing the half hole of PCB board limit, and described half hole vertically runs through PCB, and PCB metallization half hole processing technology comprises the following steps:

[0021] (1), select the PCB core board, the PCB core board includes an insulating layer and two copper-clad laminates fixed on both sides of the insulating layer;

[0022] (2), the inner layer circuit, etch the inner layer circuit on the copper clad laminate on the PCB core board;

[0023] (3) Pressing, pressing the outer layer board to the inner core board to form a PCB mother board, the PCB mother board includes the effective area of the PCB and the waste edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com