Cleaning device for cleaning optical lens

A technology for optical lenses and cleaning devices, which is applied to cleaning methods using tools, cleaning methods using liquids, and cleaning flexible objects, etc. It can solve problems such as poor fluidity of cleaning agents, slow speed of detaching from cleaning parts, and affecting ultrasonic cleaning efficiency. , to achieve the effect of improving fluidity, accelerating shedding, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

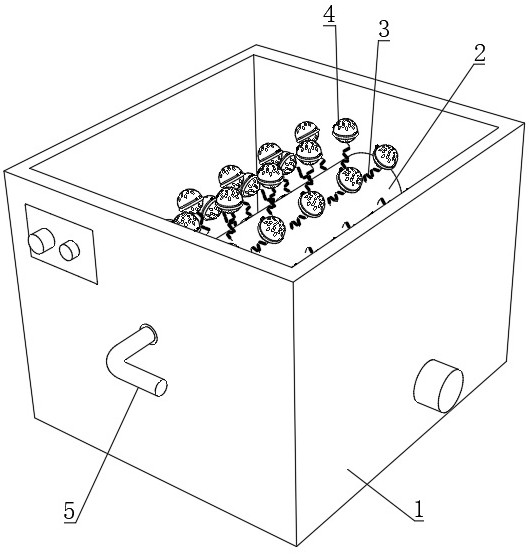

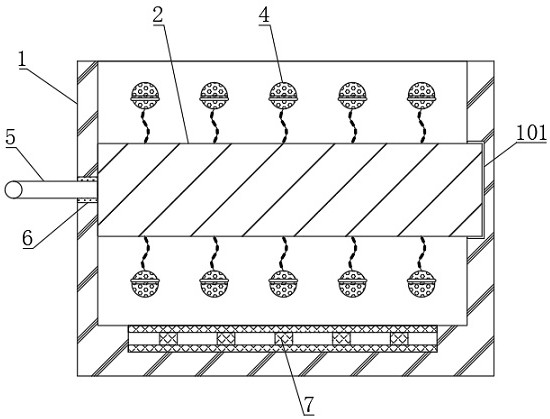

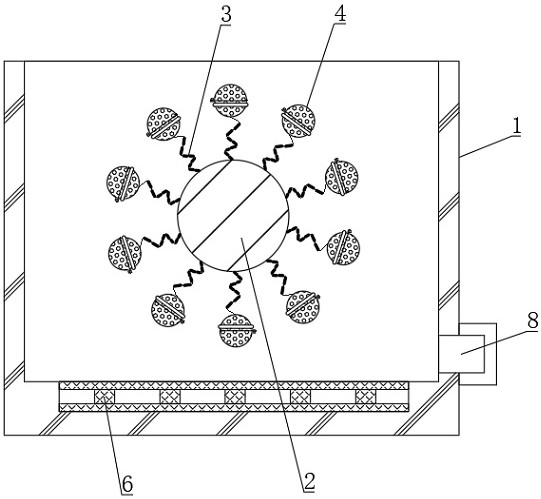

[0046] see Figure 1 to Figure 3 , a cleaning device for cleaning optical lenses, comprising a cleaning box 1, an operation panel is installed on the cleaning box 1, a rotating rod 2 is arranged inside the cleaning box 1, and a plurality of uniformly distributed The bamboo rope 3, the end of the bamboo rope 3 far away from the rotating rod 2 is fixedly connected with the touch cleaning ball cover 4, the inner bottom of the cleaning box 1 is fixedly connected with the ultrasonic generator 7, and the inner wall of the cleaning box 1 is provided with a turning groove 101, one end of the rotating rod 2 is rotatably connected to the inside of the rotating groove 101, the end of the rotating rod 2 away from the rotating groove 101 is fixedly connected with the rotating handle 5, and the cleaning box 1 is provided with a rotating hole on the inner wall close to the rotating handle 5, and the rotating handle 5 The end away from the rotating rod 2 runs through the rotating hole and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com