Multi-station drilling equipment

A drilling equipment, multi-station technology, applied in drilling/drilling equipment, metal processing equipment, boring/drilling and other directions, can solve problems affecting the accuracy of hole processing, displacement stuck, hard wear on the surface of the drill and other problems to achieve the effect of facilitating the change of the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 to attach Figure 6 Shown:

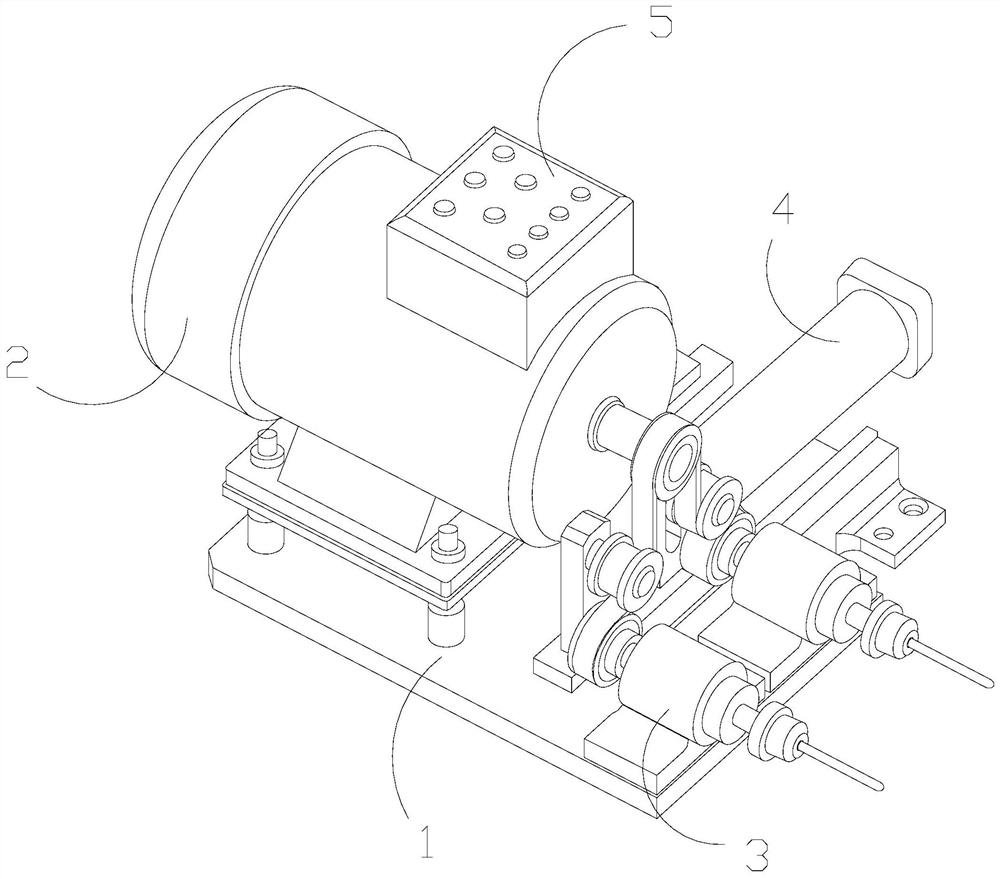

[0032] The invention provides a multi-station drilling equipment, the structure of which is provided with a base 1, a total motor 2, an operating device 3, an auxiliary machine 4, and a control box 5, the total motor 2 is located above the base 1, and the operating device 3 Installed on the front end of the main engine 2 and movably matched, the auxiliary machine 4 is installed on one side of the operating device 3 , and the control box 5 is installed on the top of the main engine 2 .

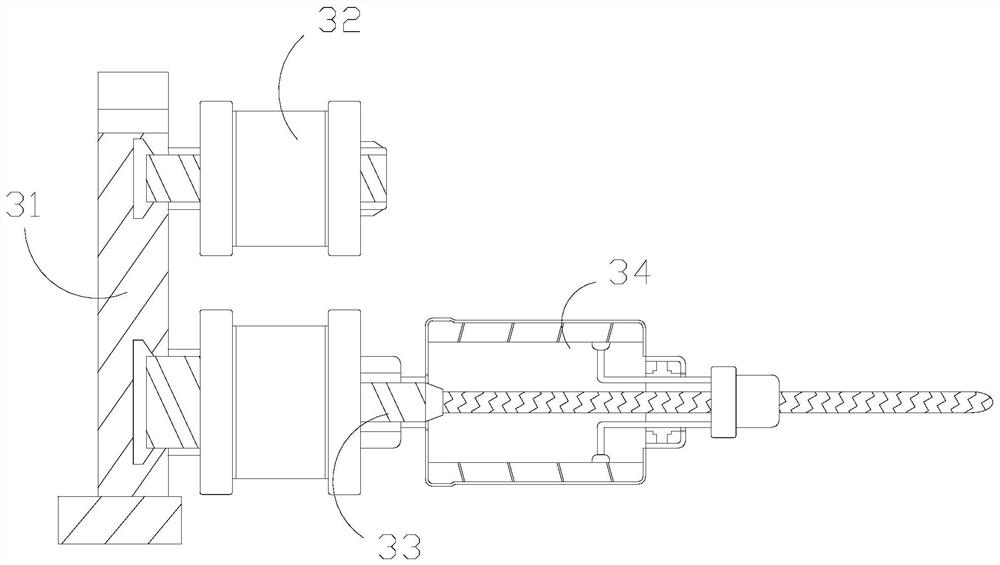

[0033] The operating device 3 is provided with a riser frame 31, a pressing frame 32, a driving turntable 33, and a drilling mechanism 34. The pressing frame 32 is movably connected in front of the vertical frame frame 31, and the driving turntable 33 is located on the pressing frame. 32 below and movably matched, the drilling mechanism 34 is connected to the front end of the driving turntable 33 .

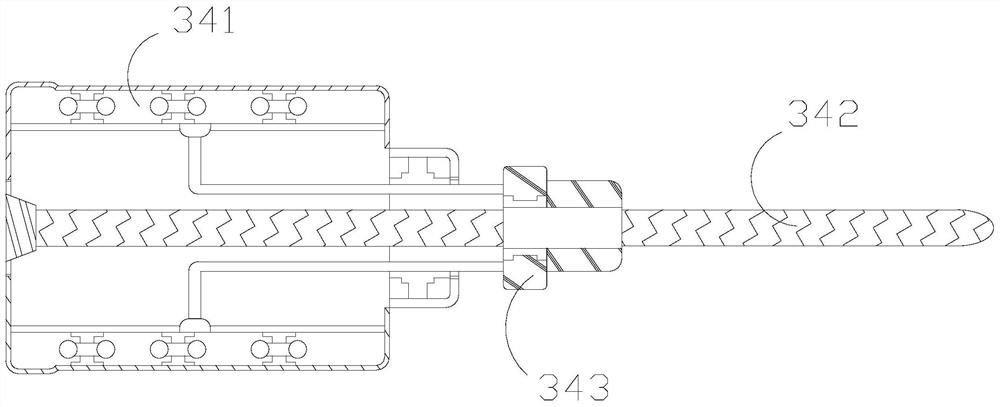

[0034] Wherein, the drilling mechan...

Embodiment 2

[0040] as attached Figure 7 to attach Figure 9 Shown:

[0041] Wherein, the tilting plate a34 is provided with a shoveling plate c1, a storage groove c2, a pendulum folded plate c3, and a spring steel c4. The folding plate c3 is hingedly connected to the upper end of the shovel plate c1, the spring steel c4 is embedded and moved in the receiving groove c2, and one end of the receiving groove c2 is connected with the bottom end of the pendulum folding plate c3 and movably matched, and the spring steel c4 It is arc-shaped and has elastic strength. The upper port of the receiving groove c2 is open. The swing plate c3 can be folded to a certain extent with the cooperation of the spring steel c4. The swing plate c3 cooperates with the shovel plate c1 , two inclined plates can be used for waste removal, and the shoveled waste can be actively brought into the storage tank c2 by the swing of the swing plate c3.

[0042] Wherein, the pendulum folding plate c3 is provided with a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com