Slicing device convenient to position based on computer technology

A slicing device and computer technology, applied in metal processing and other fields, can solve problems such as inability to realize automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

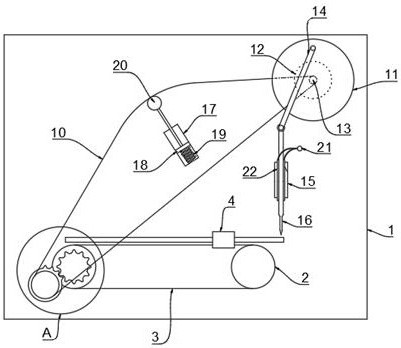

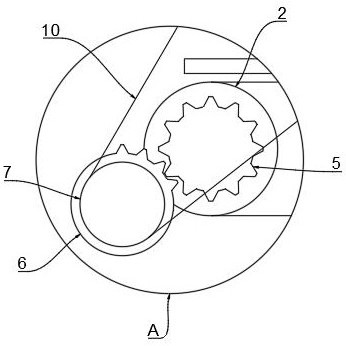

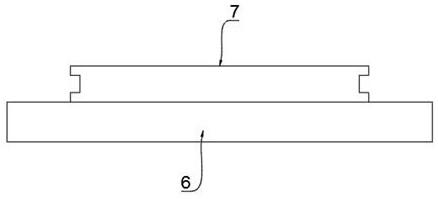

[0031] refer to Figure 1-5 , a slicing device based on computer technology for easy positioning, including a support plate 1, two pulleys-2 are installed on the support plate 1, and a conveyor belt 3 is set on the two pulleys-2, and the pulley-2 on the left side The outer wall is fixedly connected with a gear one 5, and the outer wall of the support plate 1 is equipped with a gear two 6 meshing with the gear one 5, the gear two 6 is an incomplete gear, and the outer wall of the gear two 6 is fixedly connected with a pulley two 7, the gear One 5 is consistent with the diameter of the gear two 6, the diameter of the pulley two 7 is greater than the diameter of the gear two 6, the outer wall of the support plate 1 is fixedly embedded with a motor 12, the driving end of the motor 12 is fixedly provided with a pulley three 13, the motor The driving end of 12 is fixedly connected with a turntable 11, the diameter of the pulley three 13 is consistent with the diameter of the pulley ...

Embodiment 2

[0038] The tensioning mechanism includes a connecting pipe 17 fixed on the outer wall of the support plate 1. A sliding plate 18 is slidably arranged in the connecting pipe 17. The lower side wall of the connecting pipe 17 is threadedly connected with a threaded rod 23, and the lower side wall of the sliding plate 18 is fixedly embedded. A bearing is provided, the upper end of the threaded rod 23 is fixedly embedded in the bearing, the upper side wall of the sliding plate 18 is fixedly connected with a strut, the end of the strut is equipped with a tension pulley 20, and the belt 10 is wound around the tension pulley 20 to set When adjusting the tension of the belt 10, the threaded rod 23 is rotated, and the threaded rod 23 rotates in the bearing and drives the sliding plate 18 to move back and forth, changing the tightness between the tensioning pulley 20 and the belt 10, and realizing the tightness of the belt 10. adjust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com