Reactive organic silicon thixotropic agent, organic silicon packaging adhesive and LED element

A reactive silicone and thixotropic agent technology, which is applied in the direction of electrical components, adhesives, electrical solid devices, etc., can solve the problems of easy turbidity of packaged products, poor compatibility, and difficulty in obtaining high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0103]

[0104] The present invention also provides a method for preparing the reactive silicone thixotropic agent, which includes: making the cyclic hydrogen-containing polysiloxane or the branched hydrogen-containing polysiloxane and the unsaturated polyether , under the condition that the ratio of the total amount of SiH bonds in the cyclic hydrogen-containing polysiloxane or the branched hydrogen-containing polysiloxane to the total amount of ethylenic bonds in the unsaturated polyether is greater than 1, carry out Hydrosilylation reaction.

[0105] In order to promote the smooth progress of the reaction, in the present invention, the hydrosilylation reaction is preferably carried out in the presence of a hydrosilylation reaction catalyst. In the present invention, there is no particular limitation on the type of the hydrosilylation reaction catalyst, and a known type in the art can be used. Examples of the hydrosilylation reaction catalyst include, but are not limited ...

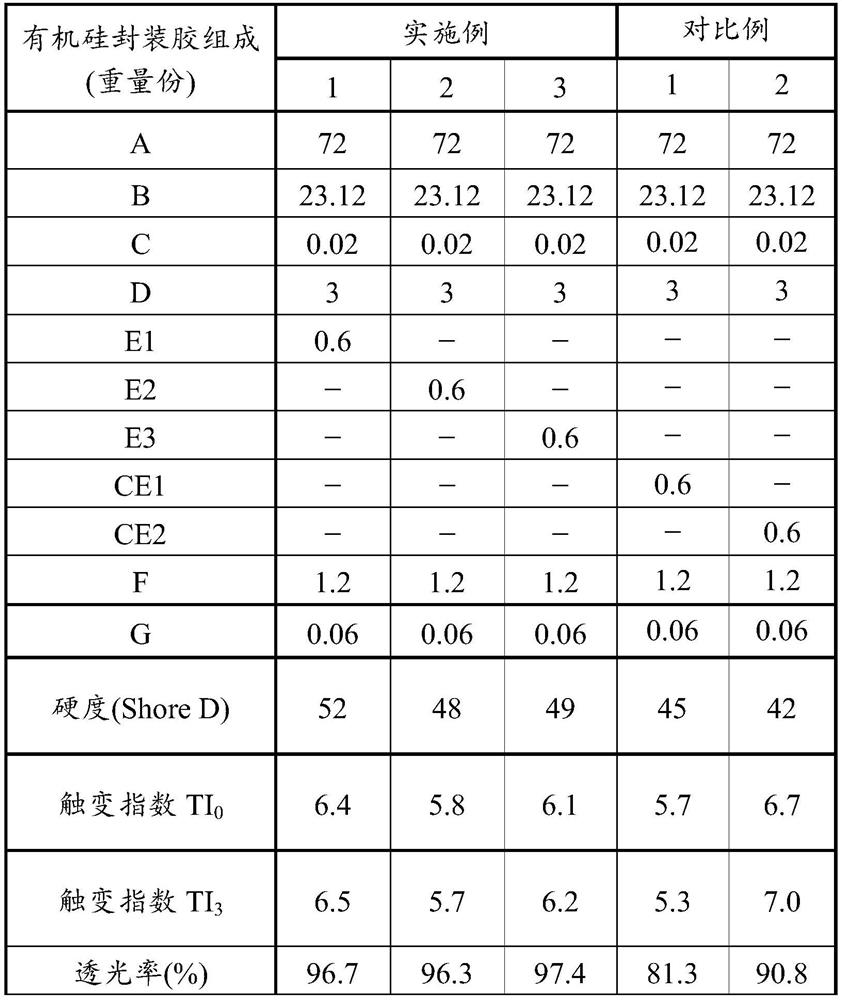

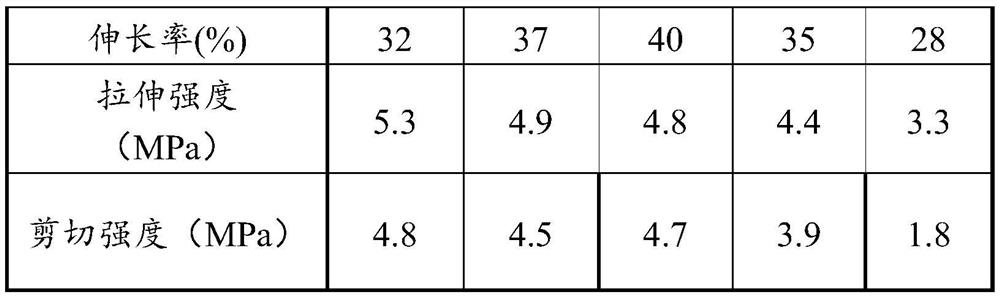

Embodiment 1 to 3 and comparative example 1 to 2

[0216] The raw materials that embodiment of the present invention 1~3 and comparative example 1~2 use are as follows:

[0217] Organopolysiloxane (A): an organopolysiloxane having a structure represented by the following formula (4-1), having a phenyl group content of 20.9% by weight and a vinyl group content of 1.92 mmol / g.

[0218] (Me 2 ViSiO 1 / 2 ) 0.34 (Me 2 SiO 2 / 2 ) 0.2 (MeSiO 3 / 2 ) 1.02 (PhSiO 3 / 2 ) 0.48 (4-1)

[0219] Hydrogen-containing polysiloxane (B): a hydrogen-containing polysiloxane having a structure represented by the following formula (5-1).

[0220] (Me 2 HSio 1 / 2 ) 2 (Ph 2 SiO 2 / 2 ) 1 (5-1)

[0221] Hydrosilylation reaction catalyst (C): platinum(0)-1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex (platinum content: 0.5 wt%).

[0222] Filler (D): fumed silica, particle size 14nm, BET specific surface area 230m 2 / g.

[0223] Reactive tackifier (E1): prepared in Synthesis Example 1.

[0224] Reactive tackifier (E2): prepared in Synthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com