A kind of nuclear entropy alloy system and its preparation method and application

A technology of entropy alloys and systems, applied in the field of high/medium entropy alloy materials and their preparation, can solve problems such as poor toughness, improve high temperature resistance and corrosion resistance, simple preparation method, excellent high temperature stability and acid corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

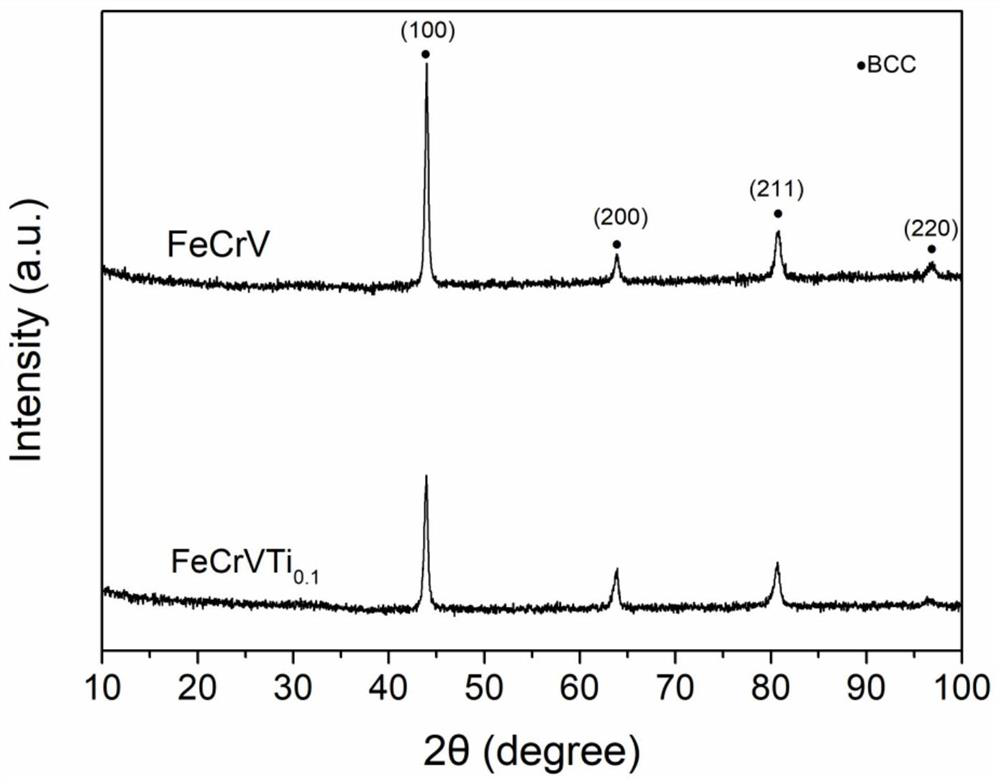

Embodiment 1

[0068]A kind of FeCrV medium-entropy alloy with low activation, high temperature resistance, high strength and high toughness for nuclear use, which is composed of three low activation elements Fe, Cr and V, wherein the atomic molar ratio of Fe, Cr and V is 1: 1:1. The preparation method of entropy alloy in FeCrV specifically comprises the steps:

[0069] Step 1, raw material handling and weighing ratio:

[0070] First, remove impurities and oxides on the surface of Fe, Cr, V and M metal single-mass blocks with a purity greater than 99.9wt% by sanding; then use acetone, alcohol and deionized water to clean in an ultrasonic cleaner for 5min (ultrasonic power The density is 0.8W / cm 2 , the frequency is 33Hz), and the clean Fe, Cr, V and M metal elements are obtained after drying with a hair dryer for future use. The spare metal element was weighed with a high-precision balance (accuracy: 0.0001g), wherein the mass percentages of Fe, Cr and V were 35.17%, 32.75% and 32.08% in ...

Embodiment 2

[0074] A kind of FeCrVTi with low activation, high temperature resistance, high strength and high toughness for nuclear use 0.05 A medium-entropy alloy, which is composed of four low-activation elements Fe, Cr, V, and Ti, wherein the atomic molar ratio of Fe, Cr, V, and Ti is 1:1:1:0.05. FeCrVTi 0.05 The preparation method of medium entropy alloy specifically comprises steps with embodiment 1.

[0075] The difference between this example and Example 1 is that the mass percentages of Fe, Cr, V and Ti are 34.65%, 32.26%, 31.60% and 1.48% in turn, that is, the metal elements of Fe, Cr, V and Ti are weighed in order 3.465g, 3.226g, 3.160g and 0.148g.

[0076] Other is the same as embodiment 1, FeCrVTi 0.05 The medium entropy alloy is prepared. .

Embodiment 3

[0078] A kind of FeCrVTi with low activation, high temperature resistance, high strength and high toughness for nuclear use 0.1 A medium-entropy alloy, which is composed of four low-activation elements Fe, Cr, V, and Ti, wherein the atomic molar ratio of Fe, Cr, V, and Ti is 1:1:1:0.1. FeCrVTi 0.1 The preparation method of medium entropy alloy specifically comprises steps with embodiment 1.

[0079] The difference between this example and Example 1 is that the mass percentages of Fe, Cr, V and Ti are 34.14%, 31.79%, 31.14% and 2.93% in turn, that is, the metal elements of Fe, Cr, V and Ti are weighed in order are 3.414g, 3.179g, 3.114g and 0.293g.

[0080] Other is the same as embodiment 1, FeCrVTi 01 The medium entropy alloy is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com