Asphalt concrete surface layer construction joint treatment method

A technology of asphalt concrete and asphalt surface layer, which is applied in the fields of highway, civil aviation, and municipal roads. It can solve problems such as low joint bonding strength, cracking of the road surface, and damage to the asphalt surface layer, so as to improve the smoothness and smoothness, and slow down the temperature. Dissipate and reduce the effect of aggregate voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

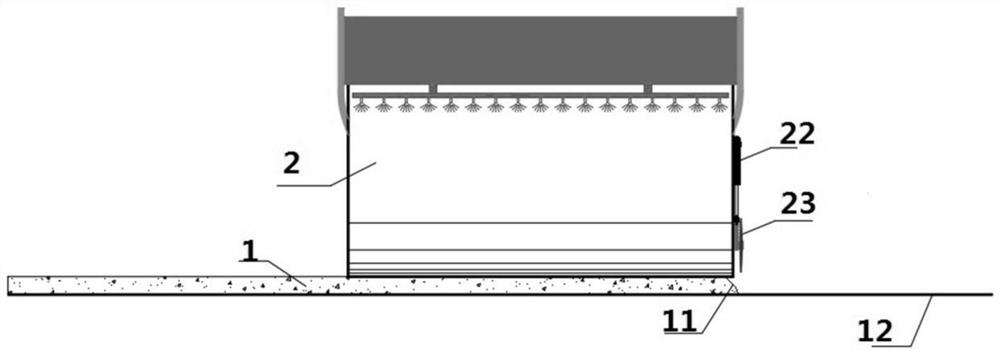

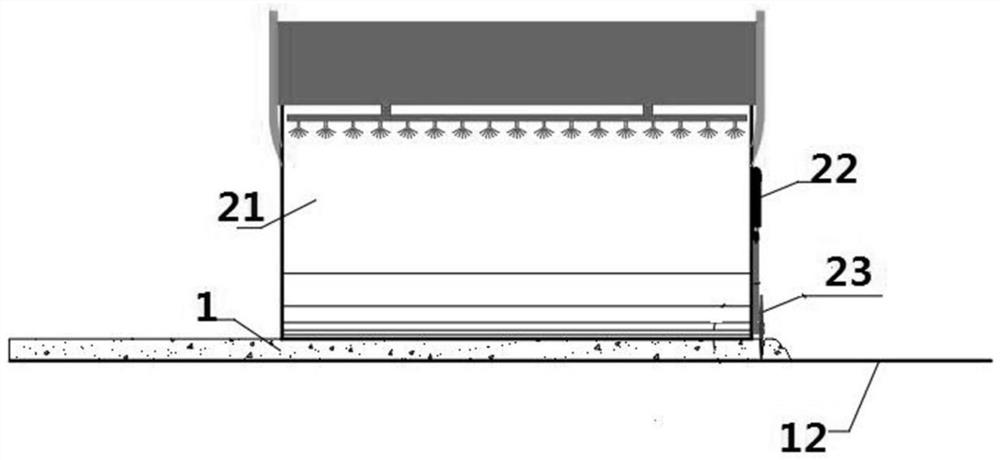

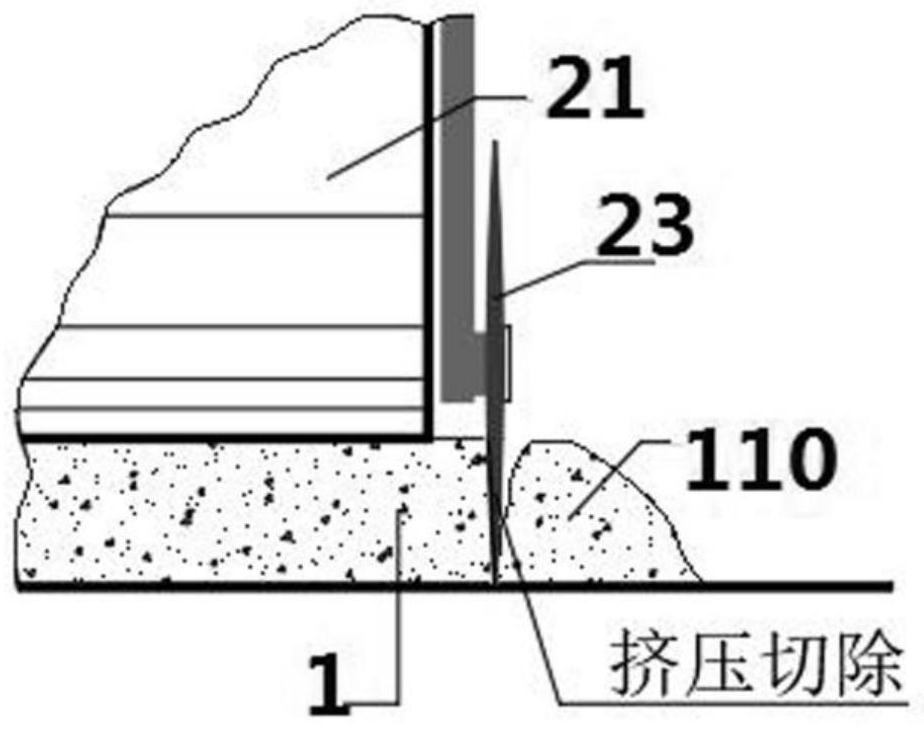

[0022] see Figure 1-6 A kind of asphalt concrete surface layer construction joint treatment method shown, comprises the following steps:

[0023] (1) First pave the asphalt concrete surface layer 1 in the standard section, and the road roller 2 will follow up in time to roll the asphalt concrete surface layer 1 first, and complete the initial pressure of the full-width asphalt surface layer and re-compacting; the road roller 2 acts on the asphalt concrete surface layer 1 laid earlier to complete the rolling of the asphalt surface layer 1 laid earlier, and the longitudinal joint 11 of the asphalt pavement is arranged on the side of the asphalt concrete surface layer 1 laid first, and the asphalt pavement One side of the longitudinal joint 11 is provided with a post-paved wideni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com