Eccentric annular large-cantilever prestressed steel structure system and construction method thereof

A technology of prestressed steel and large overhangs, applied in special structures, building components, building structures, etc., can solve problems such as difficulty in achieving architectural effects, structural self-heaviness, and inability to meet the needs of large internal spaces in buildings. Safety and economy, and the effect of improving vertical rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

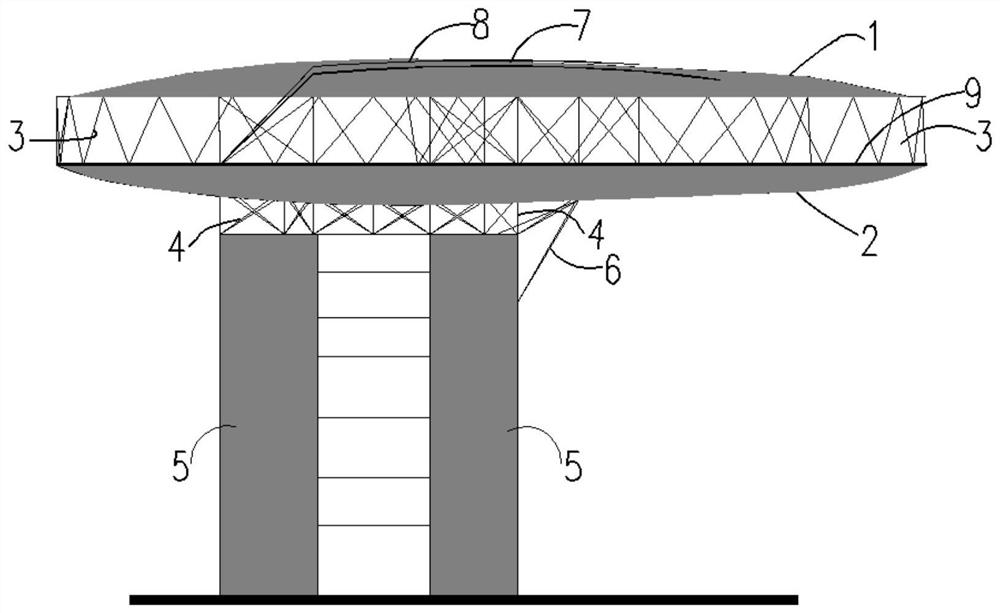

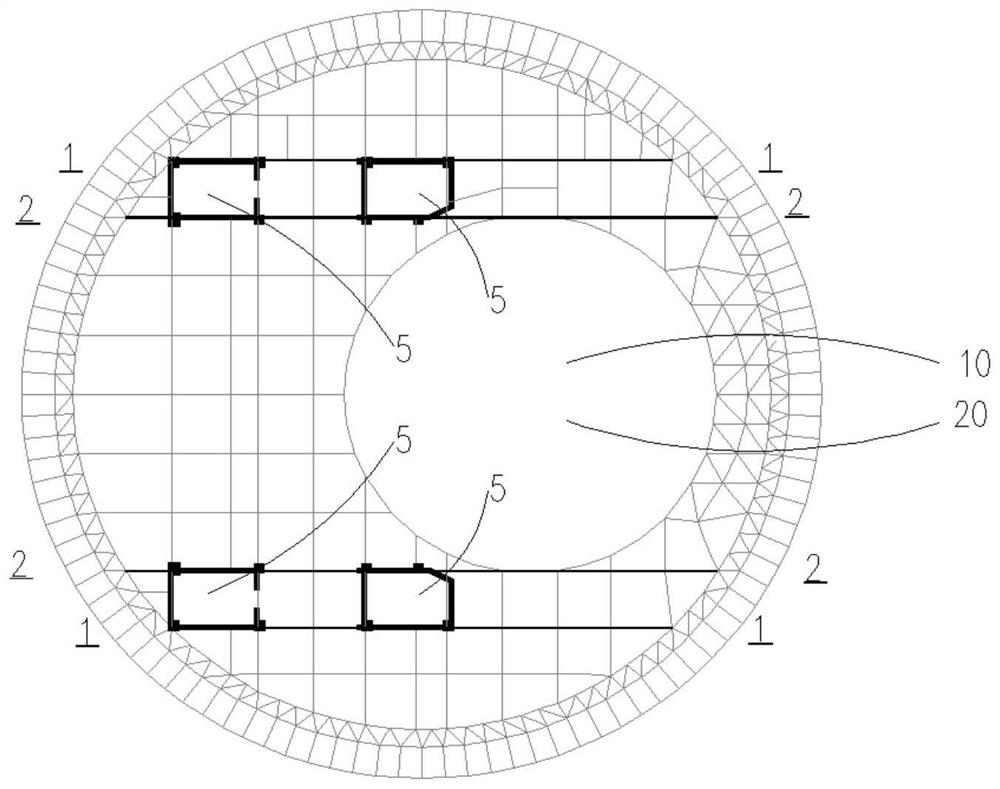

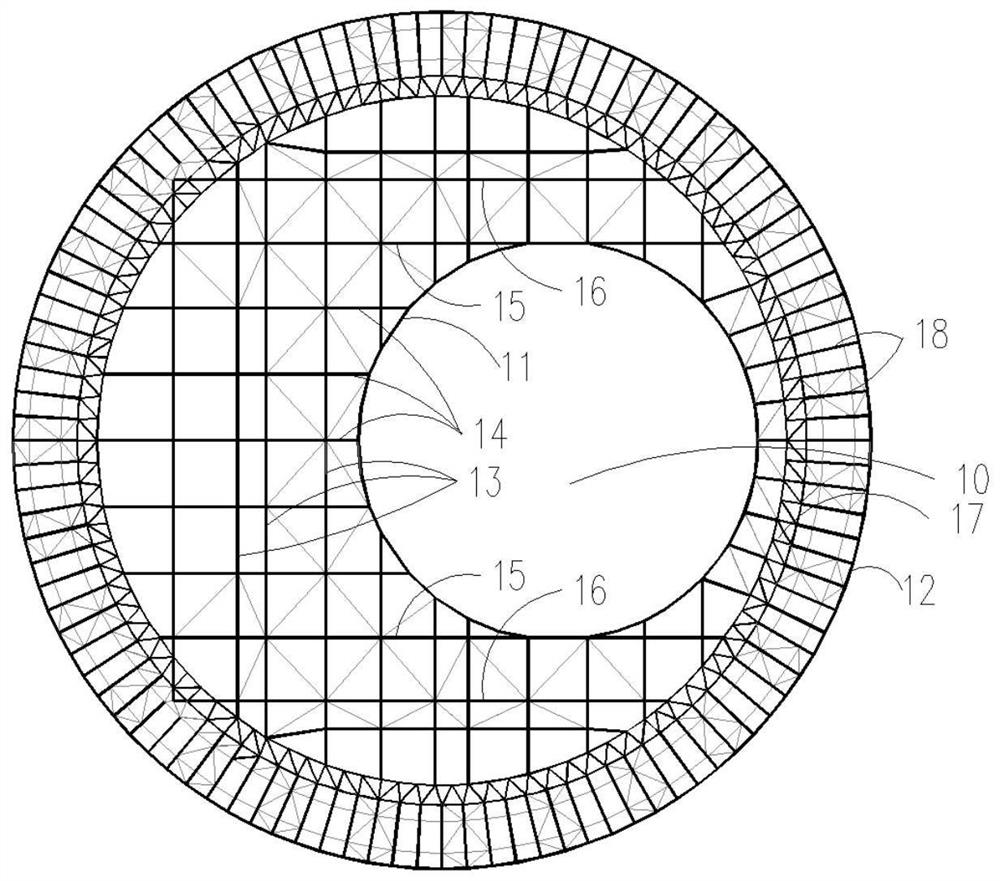

[0058] Such as Figure 1-14 An eccentric annular large cantilever prestressed steel structure system of the present invention includes: a roof structure layer 1, a floor structure layer 2, an interlayer connecting support 3, a partial transfer truss 4 on the top of a concrete core tube, and a concrete core tube 5 , Large cantilever reinforced diagonal bracing 6, prestressed cable 7, cable steel connection node 8, floor slab 9. The component layout of the roof structure layer 1 and the floor structure layer 2 is consistent with the axis of the concrete core tube 5; The conversion truss 4 at the top of the core tube is connected to the concrete core tube 5; the prestressed cable 7 at the cantilever end is set on the upper chord of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com