Large-scale equipment online monitoring and fault prediction system

A large-scale equipment and fault prediction technology, which is applied to fuzzy logic-based systems, measurement devices, design optimization/simulation, etc., can solve problems such as inaccurate prediction results, and achieve the effect of ensuring safe and reliable operation and realizing fault prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

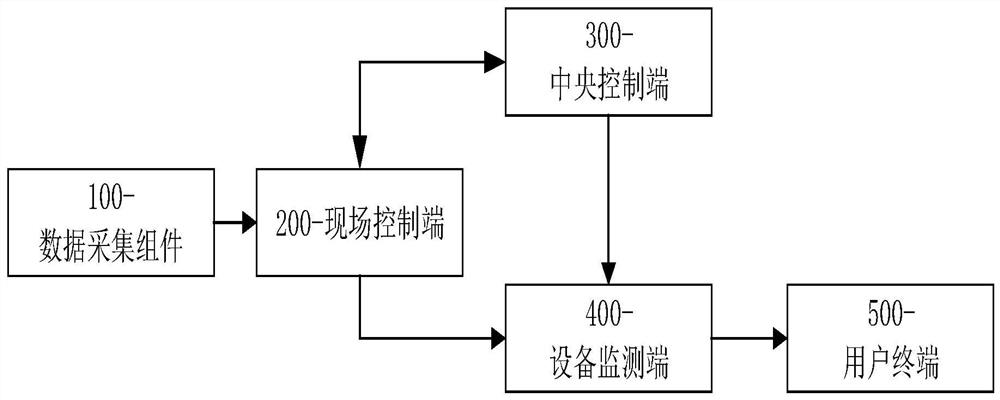

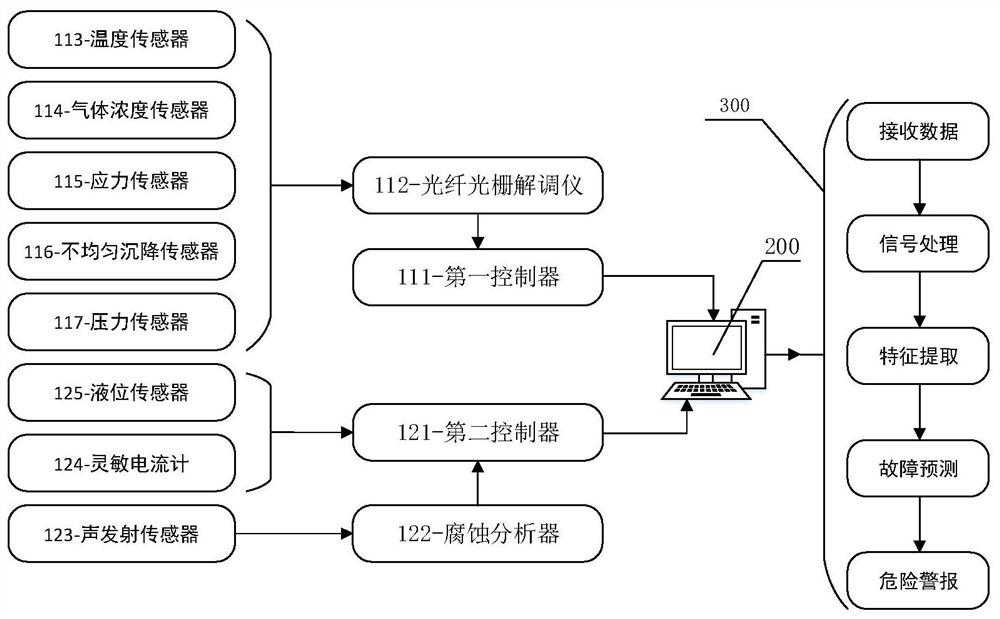

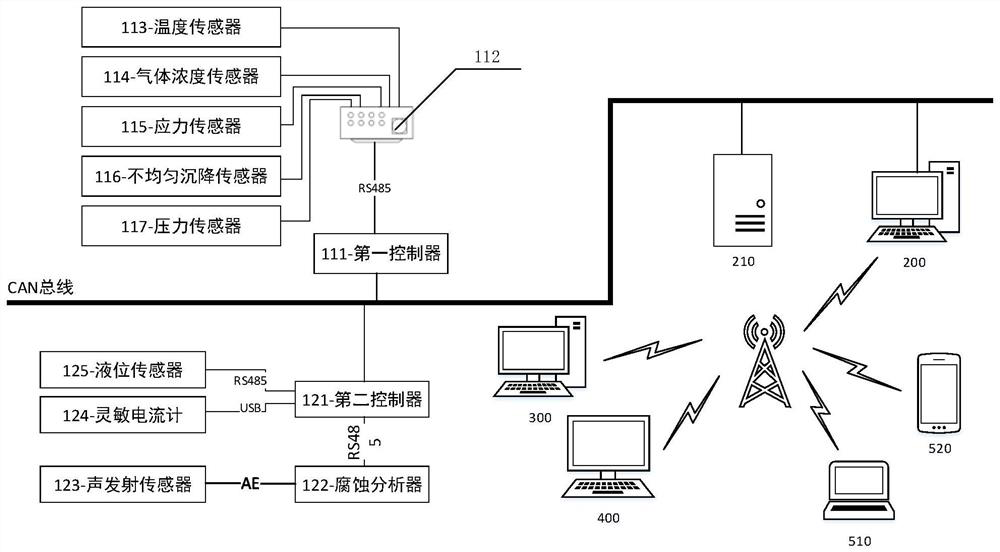

[0035] Reference attached Figure 1-6 As shown, the embodiment of the present application provides an equipment online monitoring and fault prediction system. The system includes: a data acquisition component 100 , a field control terminal 200 , a central control terminal 300 , an equipment monitoring terminal 400 and a user terminal 500 . The user terminal 500 in this embodiment may be, but not limited to, a mobile PC terminal 510 or a smart phone terminal 520 .

[0036] refer to Figure 2-3 As shown, the data acquisition component 100 in this embodiment collects one or more characteristic data in the large-scale equipment 10 in real time, including temperature, pressure, gas concentration, stress distribution, uneven settlement, liquid level, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com