Electromagnetic shielding structure manufacturing process and electromagnetic shielding structure

A technology of electromagnetic shielding structure and manufacturing process, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of short circuit of grounding shielding wires, affecting product quality, and failure of electromagnetic shielding performance of products, and achieving easy connection and electromagnetic shielding functions. The effect of stable and stable electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

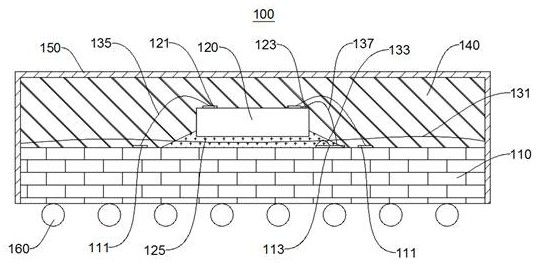

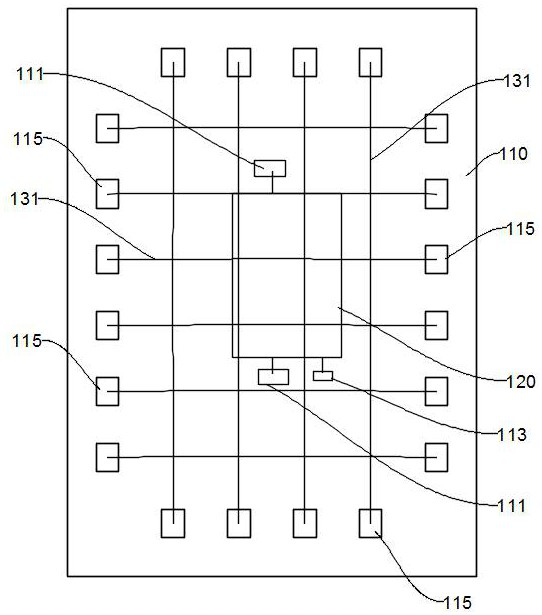

[0055] Please refer to figure 1 and figure 2 , in order to effectively prevent the electromagnetic interference generated by various chips 120 and components, an electromagnetic shielding structure 100 provided in an embodiment of the present invention includes a substrate 110 , a chip 120 , a plastic package 140 and a metal layer 150 . A first pad 111, a second pad 113, and a plurality of third pads 115 are arranged at intervals on the substrate 110, and the first pad 111 and the second pad 113 are located in the enclosed space formed by the plurality of third pads 115. Inside; a first connection line 131 with a grounding property is provided between the plurality of third pads 115 , and the chip 120 is located on the first connection line 131 . The chip 120 is electrically connected to the first pad 111 to realize the functional connection between the chip 120 and the substrate 110; the chip 120 is electrically connected to the second pad 113 to realize the grounding of th...

no. 2 example

[0062] Please refer to Figure 3 to Figure 10 , the embodiment of the present invention provides a manufacturing process of the electromagnetic shielding structure 100, the main steps of which include:

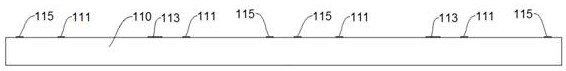

[0063] A substrate 110 is provided, and a first pad 111, a second pad 113, and a plurality of third pads 115 are formed on the substrate 110, wherein the number of the first pads 111 corresponds to the number of functional pads 121 on the chip 120, The first pad 111 is used to realize the functional connection of the chip 120, the second pad 113 is used to realize the grounding of the chip 120, and a plurality of third pads 115 are arranged at intervals and connect the chip 120, the first pad 111 and the second pad to each other. A disc 113 surrounds it. It should be noted that the first bonding pad 111 and the second bonding pad 113 are respectively arranged around the chip 120, and the third bonding pad 115 can be arranged on opposite sides of the chip 120 or around the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com