Mold for producing aluminum alloy composite piston through indirect extrusion casting technology and method thereof

An aluminum alloy and mold technology, which is applied in the field of aluminum alloy composite piston mold and its preparation, can solve the problems of high operator proficiency, low efficiency and high production cost, and achieve the effect of improving production efficiency and qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

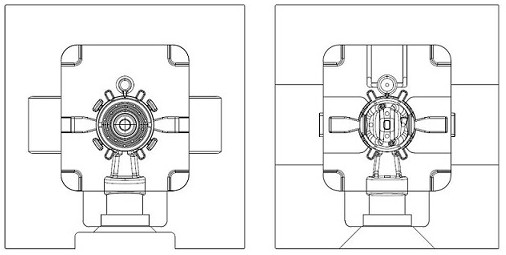

[0012] Such as figure 1 A mold for an aluminum alloy composite piston and its preparation method are shown, including a movable mold core, a fixed mold core, a sprue sleeve, an ejection system, a cooling system, two partial extrusion devices, and a fiber ring positioning device, Cast iron ring clamping system, the fiber ring positioning device is set in the middle of the fixed mold core, the cast iron ring clamping system is composed of two cylinders and clamping blocks, the salt core is placed between the fiber ring and the cast iron ring, the The cast iron ring, the fiber ring and the fiber ring positioning device are matched; the three inserts of the fiber ring, salt core and cast iron ring are placed in sequence and put into the fixed mold core at one time, which is fast, convenient and reduces the number of inserts temperature loss. The cast iron ring clamping system works, the three inserts are fixed, the local extrusion device is returned, the mold is closed, the manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com