Automatic pipe polishing machine

A polishing machine and pipe technology, applied in the field of polishing, can solve problems affecting processing efficiency and inconvenience, and achieve the effects of improving processing efficiency, saving time, and convenient replacement of grinding rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

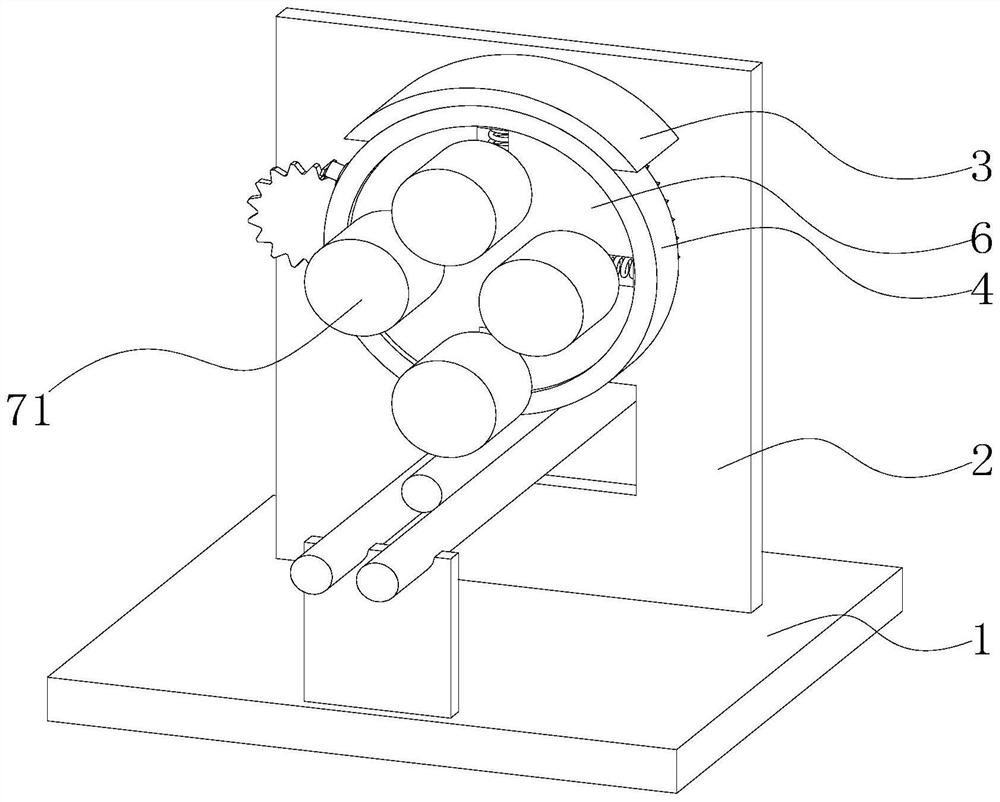

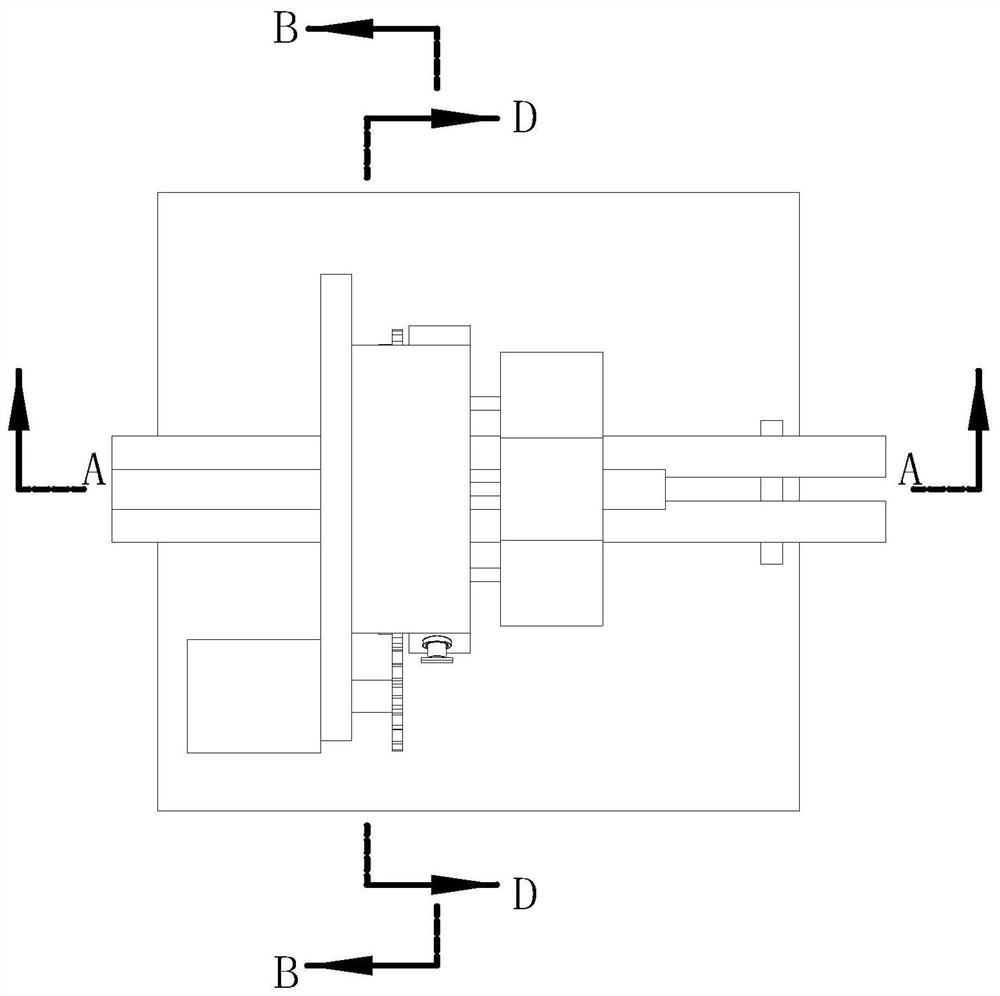

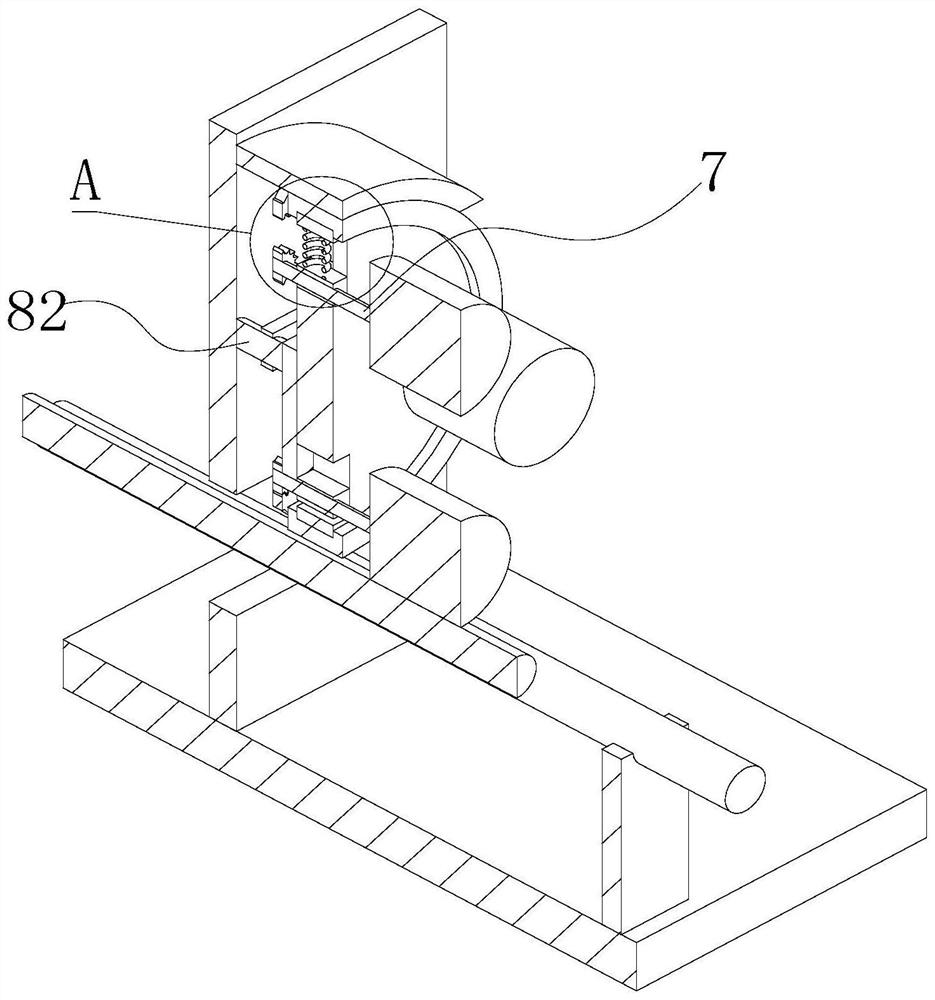

[0019] like Figure 1-7 As shown, an automatic pipe polishing machine includes a base 1, a supporting plate 2, a connecting plate 3, a sleeve 4, a turntable 6, a rotating shaft 7, a grinding roller 71, a driving device and a locking device, and the supporting plate 2 is fixed on the base. The connecting plate 3 is fixed on the support plate; the sleeve 4 is fixed on the connecting plate; the turntable 6 is rotatably connected to the sleeve; The grinding roller 71 is fixed on the rotating shaft.

[0020] Specifically, the driving device includes a first gear 81, a first connecting shaft 82, a first connecting plate 83, a ring 84, a first tooth 85, a second tooth 86, a second gear 87, a driving member and a control assembly, The number of the first gears 81 is the same as that of the rotating shaft, and they are respectively fixed on the ends of the rotating shaft; the first connecting shaft 82 is fixed on the support plate; the first connecting plate 83 is rotatably connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap