Reversing type well lid lifting device for municipal engineering construction

A technology for engineering construction and manhole covers, which is applied in hoisting devices, hoisting equipment safety devices, hoisting devices, etc., can solve problems such as inability to move and reverse hooks, and achieve the effects of easy installation and disassembly, improved safety, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

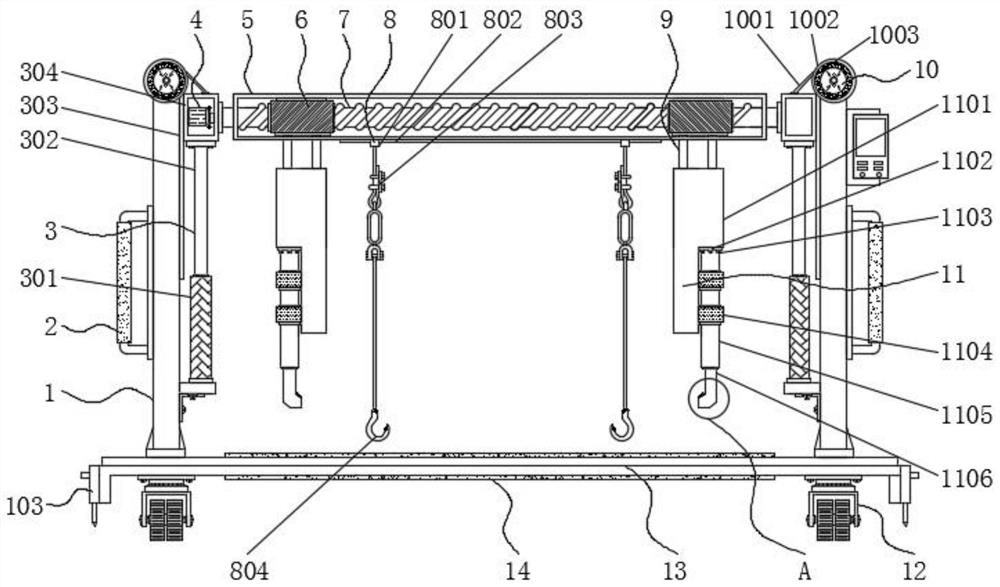

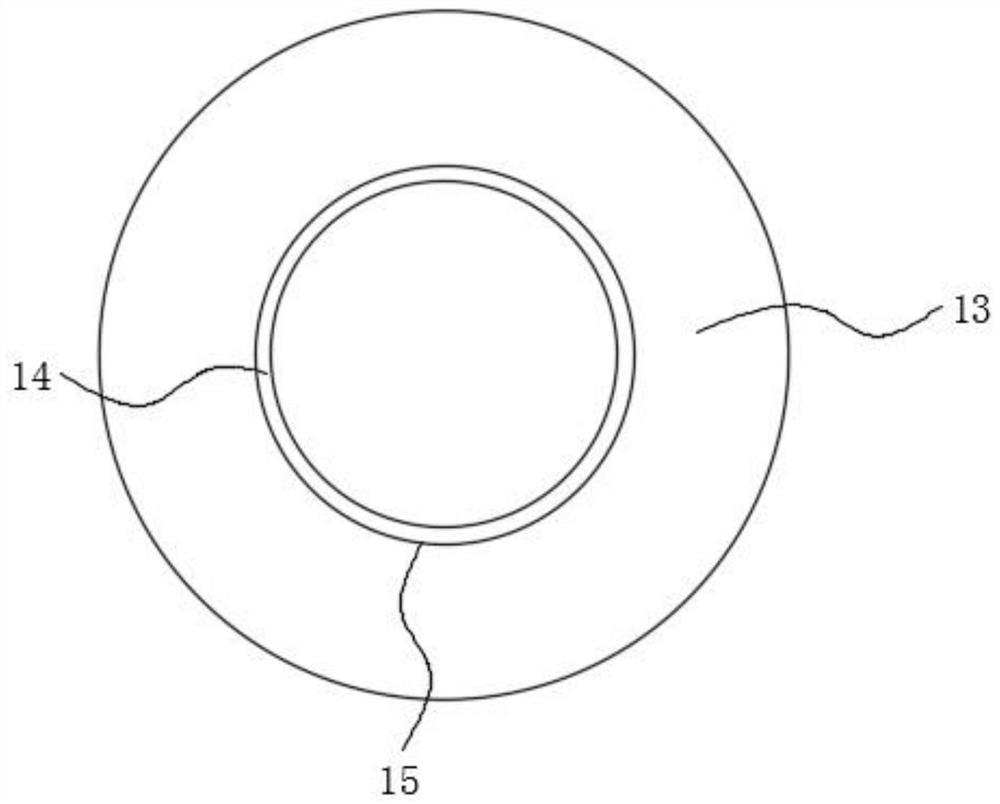

[0040] Example 1: See Figure 1-6 , a reversible manhole cover lifting device for municipal engineering construction, comprising damping wheels 12 and a base plate 13, damping wheels 12 are provided at the four corners of the bottom end of the base plate 13, mounting frames 1 are provided on both sides of the top end of the base plate 13, The outside of mounting frame 1 is fixedly connected with handrail 2, and the inboard of mounting frame 1 is provided with protective structure 3 respectively, and the top of mounting frame 1 is respectively provided with elevating mechanism 10, is provided with fixed frame 5 between the top of mounting frame 1 inner side, fixes The middle position of the bottom end of the frame 5 is provided with a buckle structure 8, the two sides of the bottom end of the fixed frame 5 are provided with a disassembly structure 11, and the inside and outside of the fixed frame 5 are provided with a moving mechanism;

[0041] see Figure 1-6 , a reversible m...

Embodiment 2

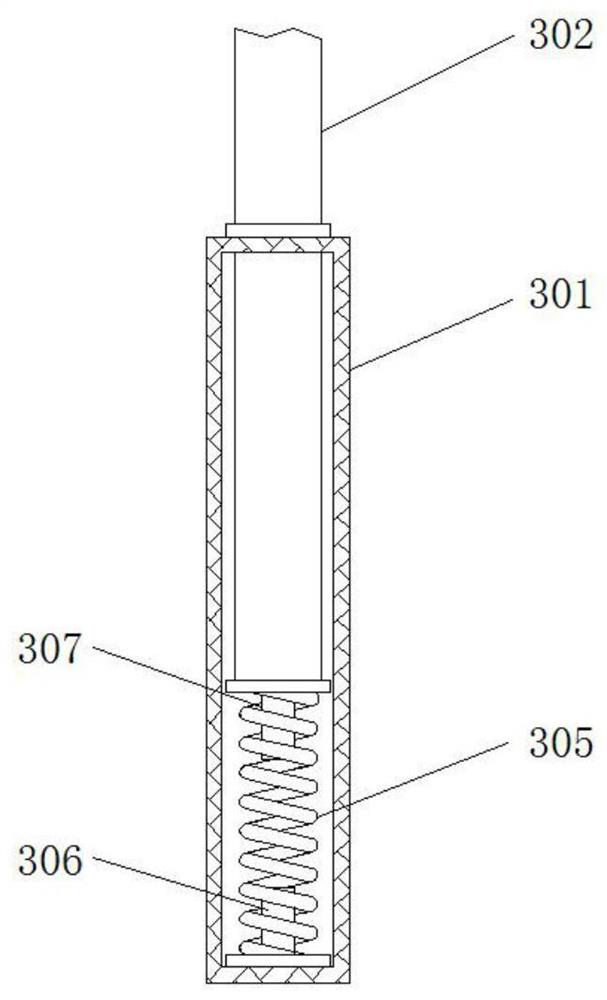

[0047] Embodiment 2: The protective structure 3 is composed of a sleeve 301, a vertical bar 302, a chute 303, a housing 304, a support spring 305, a hollow guide post 306 and a guide rod 307, and the sleeve 301 is fixedly connected to the inside of the installation frame 1, The inside of the sleeve 301 is movably connected with a vertical rod 302, and a support spring 305 is arranged between the bottom end of the vertical rod 302 and the inner bottom end of the sleeve 301, and the top end of the support spring 305 is fixedly connected with a guide rod 307, and the support spring 305 The inner bottom end is fixedly connected with a hollow guide post 306, the top end of the vertical bar 302 is fixedly connected with a housing 304, the chute 303 is arranged on the other side inside the installation frame 1, and one side of the housing 304 is embedded in the side of the chute 303. The interior is slidably connected with the chute 303;

[0048] The inner diameter of the hollow guid...

Embodiment 3

[0050] Embodiment 3: The buckle structure 8 is composed of a moving block 801, a moving groove 802, a first steel wire rope 803 and a hook 804. The moving groove 802 is arranged at the middle position at the bottom of the fixed frame 5, and a moving block 801 is embedded in the moving groove 802. , the bottom end of the moving block 801 is fixedly connected with a first steel wire rope 803, and the bottom end of the first steel wire rope 803 is fixedly connected with a hook 804;

[0051] The first steel wire rope 803 is provided with two groups, and the top of the first steel wire rope 803 is fixedly connected with the moving block 801 through a fixed buckle;

[0052] Specifically, as figure 1 As shown, some well covers at the sewer pipes are provided with elongated slotted holes, while other well covers are only provided with a handle and are hinged to open. For such well covers, move the moving block 801 inside the moving slot 802, and the hook 804 Hang the buckle on the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com