A construction method for concrete pouring of small-angle inclined piles

A construction method and concrete technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of difficult vibration, narrow space, triangular top surface, etc., reduce investment and material loss, simple construction operation, The effect of easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

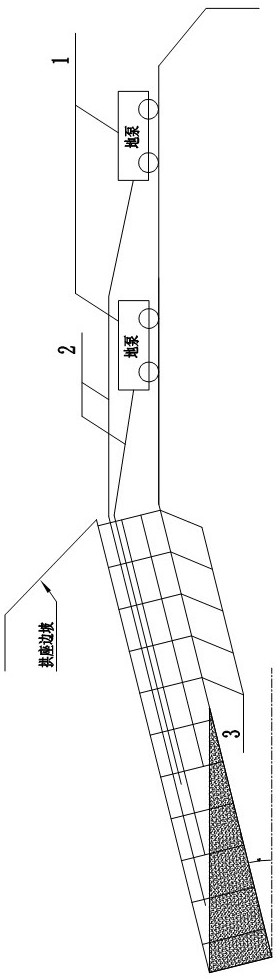

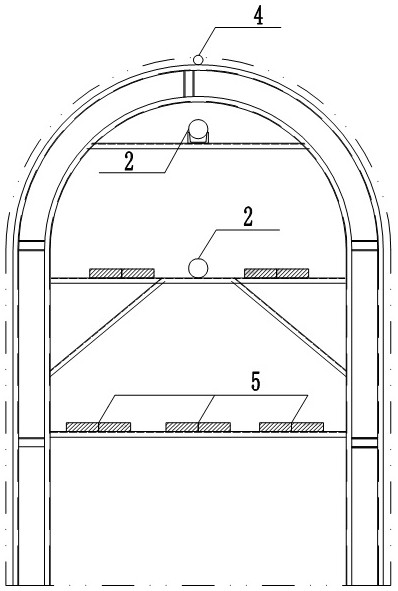

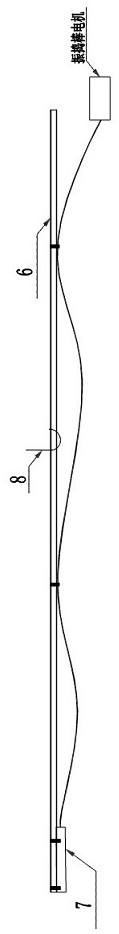

[0034] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of the present invention provides a construction method for small-angle (14°) inclined pile concrete pouring, including the following specific implementation aspects:

[0035] 1. Design the mix ratio of concrete according to relevant specifications and regulations, so that the concrete has high fluidity and long initial setting time. According to the construction needs, the initial setting time of concrete is designed to be more than 18 hours, and the slump loss is not more than 20mm for 2 hours. , to ensure that the inclined pile concrete has good working performance;

[0036] 2. Use the φ48*3.5mm welded pipe 6 with a length of 6m to lengthen the vibrating rod 7, so that the vibrating rod 7 has the ability to vibrate laterally, and carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com