Karst cave stratum pile foundation structure and pile forming process

A technology of karst caves and formations, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of waste of concrete materials, and the structural strength of the pile foundation is not easy to form, so as to achieve the effect of improving structural strength, improving construction quality, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-4 The application is described in further detail.

[0045] The embodiment of the present application discloses a pile foundation structure in karst cave strata.

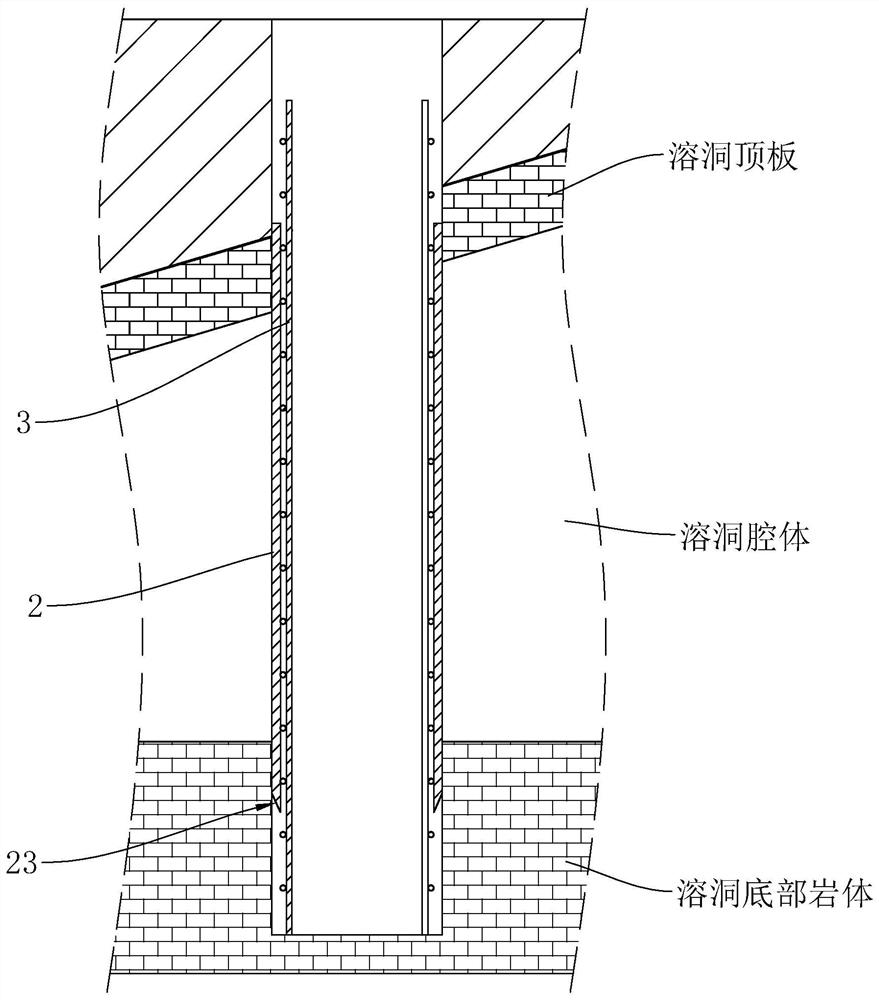

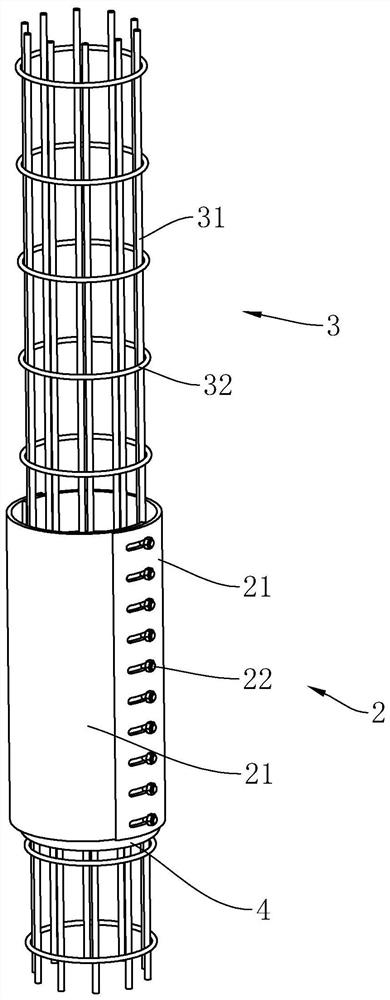

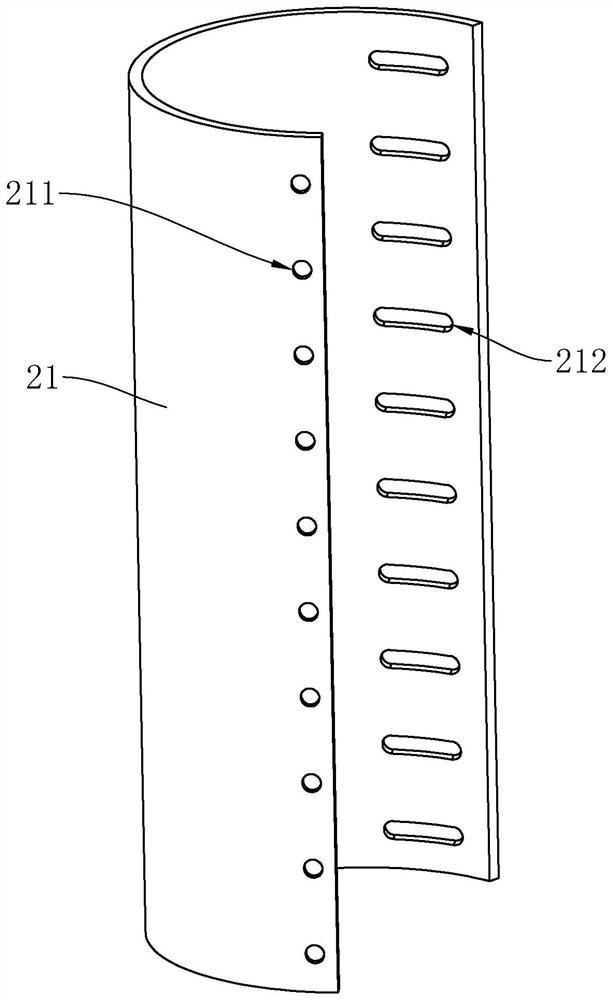

[0046] refer to figure 1, The pile foundation structure includes a borehole 1 opened on the karst cave formation, a casing 2 placed in the borehole 1 and a reinforcement cage 3 set in the casing 2 . Borehole 1 is formed vertically downwards from the ground with a rotary drilling rig, and after the borehole 1 passes through the roof above the karst cave, it passes through the cavity of the karst cave and extends to the rock mass at the bottom; the casing 2 is vertical The cylindrical structure is set, and the upper and lower ends of the casing 2 are open. The top end of the casing 2 is sleeved in the borehole 1 of the roof of the cave, and the bottom end is sleeved in the borehole 1 of the rock mass at the bottom of the cave. , that is, the casing 2 passes through the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com