Vertical hole grouting type concrete internal partition wall filling building block

A concrete inner and block technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve the problems of high water absorption rate of foamed cement, inconvenient transportation and installation, and difficult construction, and achieve water retention. Good performance, ensure the quality of masonry, and reduce the difficulty of masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

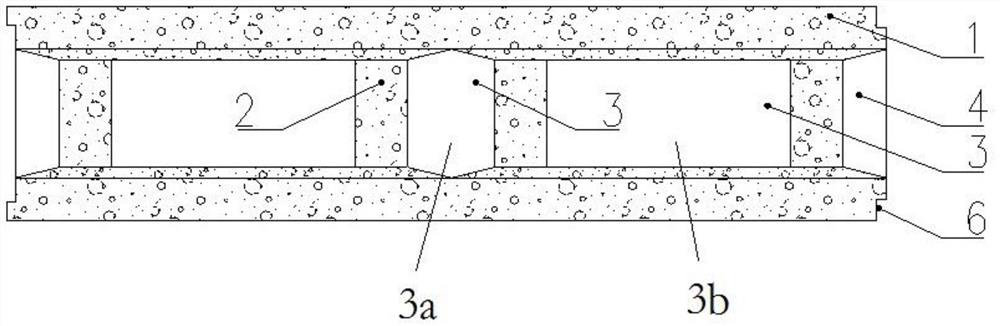

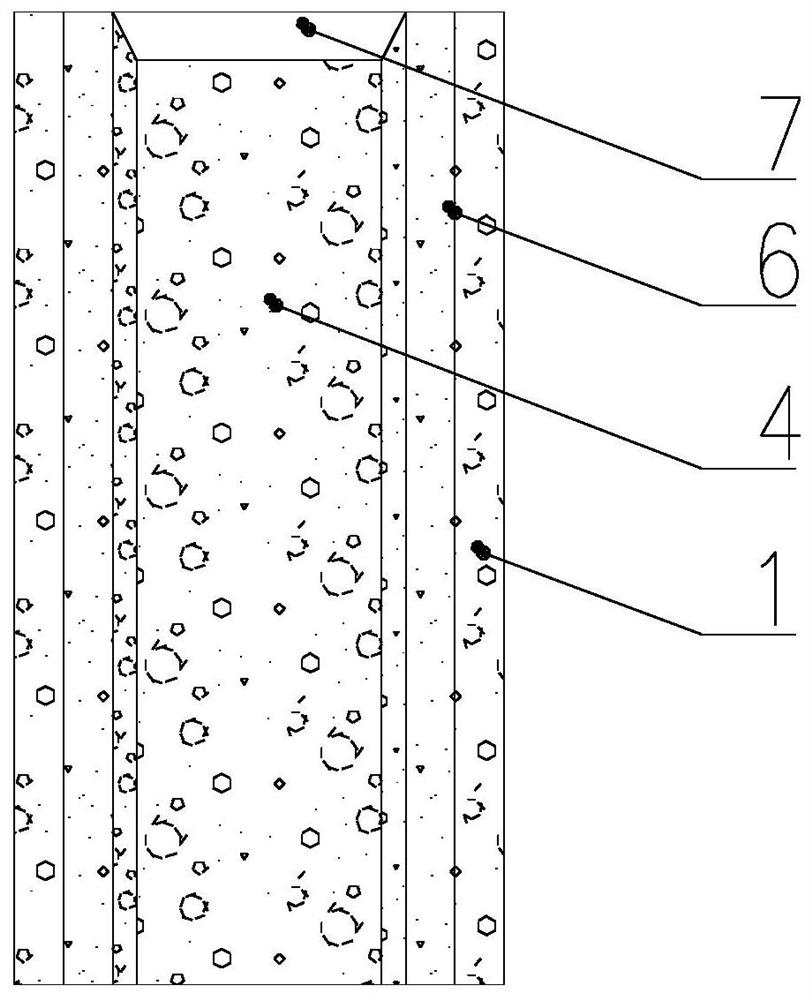

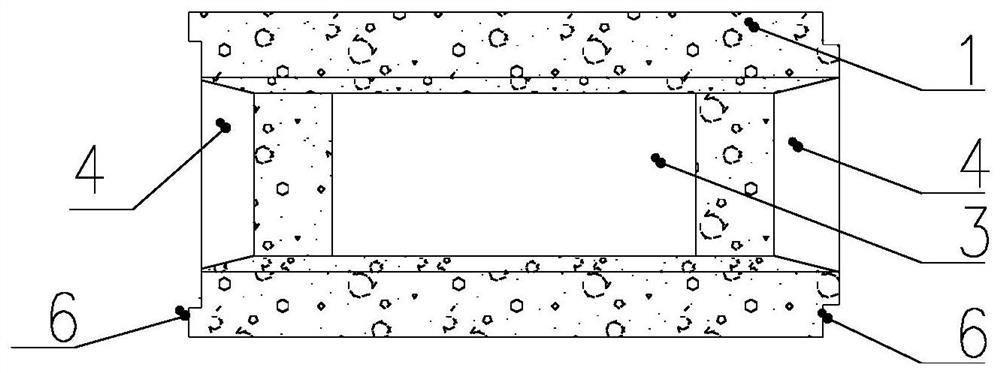

[0029] A vertical hole grouting type concrete inner partition wall structure of the present invention is formed by one or more unit blocks connected by vertical hole grouting. Each unit block includes a side plate 1 and a connecting beam 2 arranged between the side plates 1. The plate 1 and the connecting beam 2 are lightweight concrete, the outer side of the connecting beam 2 is provided with a grouting groove 4, and the inner side of the connecting beam 2 and the adjacent connecting beam 2 form a cavity 3 ( Including the grouting hole 3a, the weight-reducing cavity 3b, wherein the grouting hole 3a is grouted, and the weight-reducing cavity 3b may not be grouted).

[0030] The grouting groove 4 is a flaring groove with a small bottom and a large opening.

[0031] The top groove 7 is a flaring groove with a small bottom and a large opening.

[0032] The actual production of the present invention is that the side plate 1 and the connecting beam 2 are molded at one time in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com