A compact layout method of underground coal gangue sorting chamber group

A layout method and chamber group technology, applied in earthwork drilling, underground transportation, mining equipment, etc., can solve the problems that restrict the safe and efficient production of deep wells and the coordination of mining environment, huge environmental pressure, and insufficient lifting capacity of deep wells, etc. The effect of the amount of gangue produced and the amount of roadway excavation, reducing the amount of coal pressure, and reducing the difficulty of surrounding rock control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

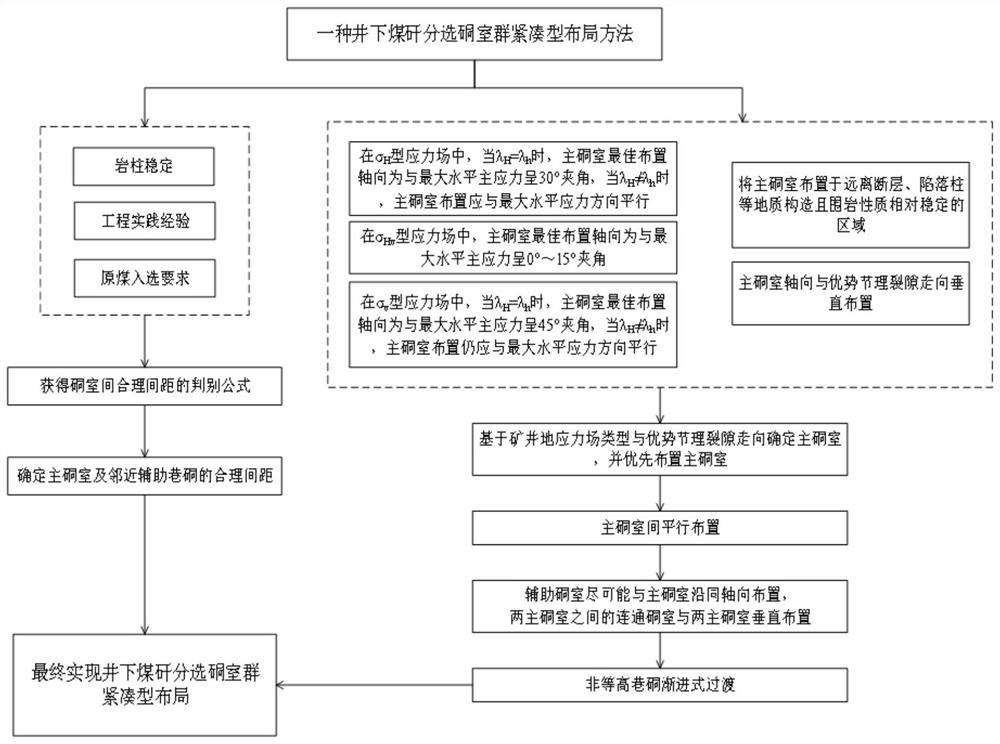

[0036] Such as figure 1 and Figure 5 As shown, the underground coal gangue sorting chamber group compact layout method of the present invention, its steps are as follows:

[0037] a Firstly, based on the type of in-situ stress field in the mine and the trend of dominant joints and fissures, determine the type and quantity of main chambers and auxiliary chambers required in the coal gangue separation chamber group, and then design the connection sequence of chambers according to the actual coal gangue separation , while ensuring that the main chambers are arranged parallel to each other when arranging the main chambers;

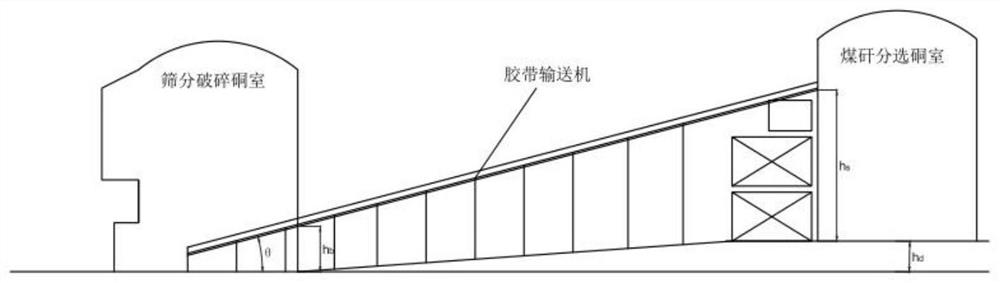

[0038] b. The auxiliary chambers are arranged in the same axial direction as the chambers. If there is an auxiliary chamber as a connecting chamber between the two main chambers, the auxiliary chambers are vertically arranged in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com