A hose and pipeline winding device for a segment assembly machine

A segment assembly machine and pipeline winding technology, which is applied to the arrangement of pipes/pipe joints/fittings, hoses, reelers/photosensitive drums, etc., which can solve the problems of reducing bearing capacity, increasing costs, and high failure rates. problem, to achieve the effect of large rim channel capacity, improved load capacity and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

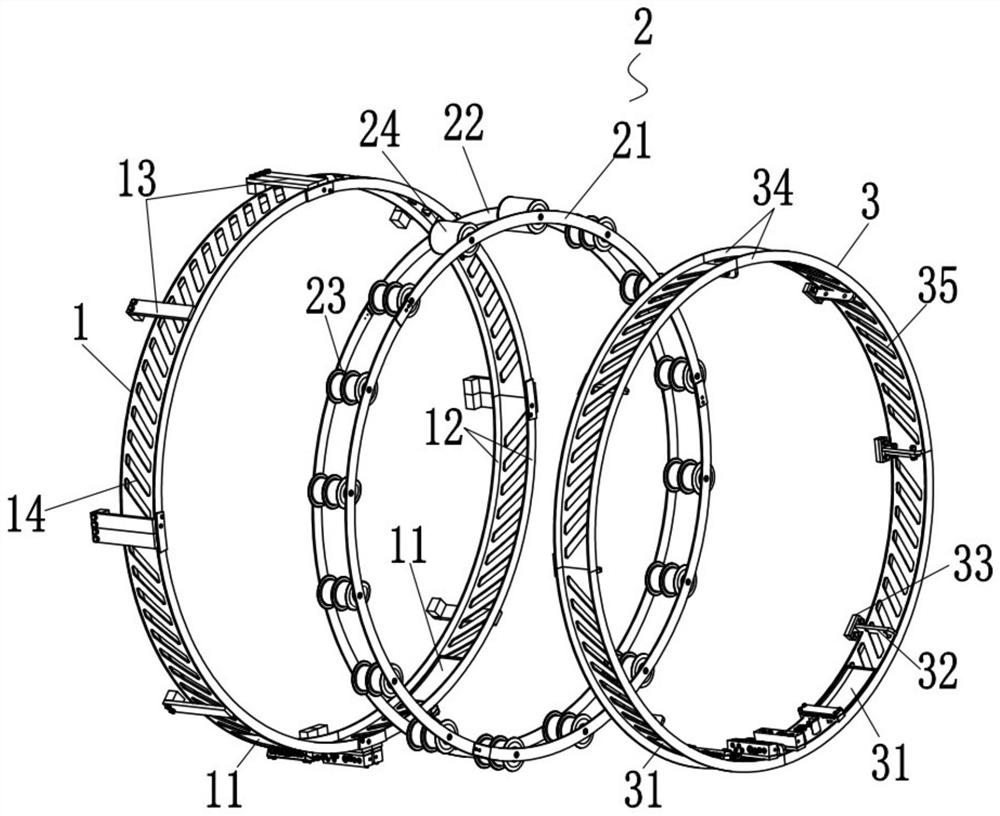

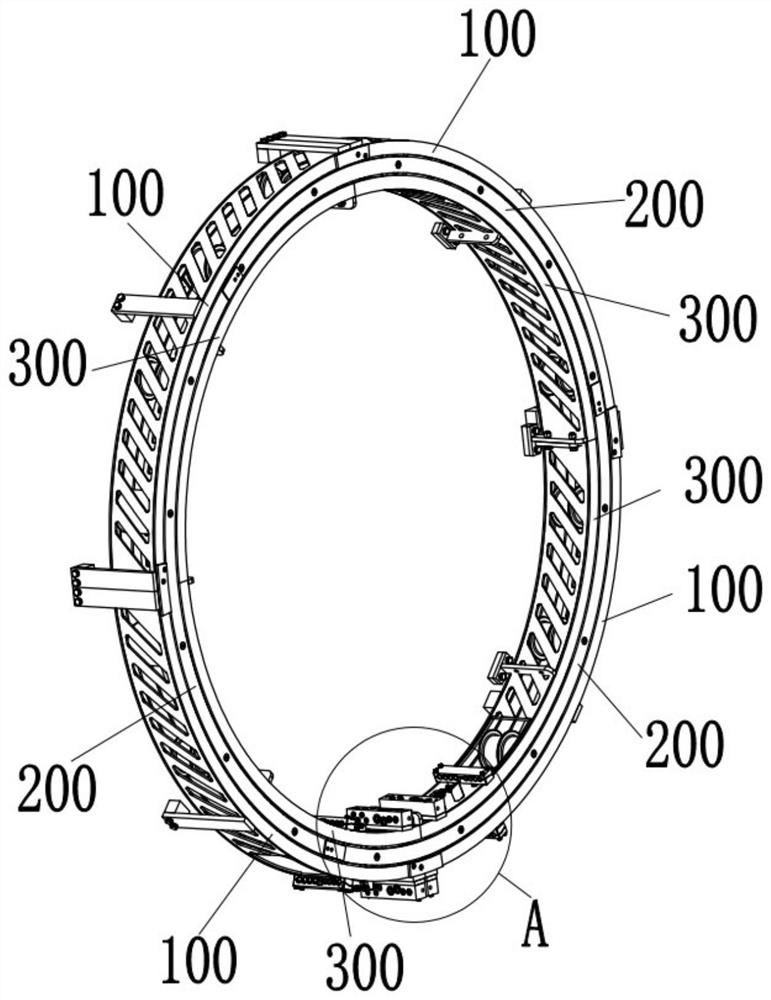

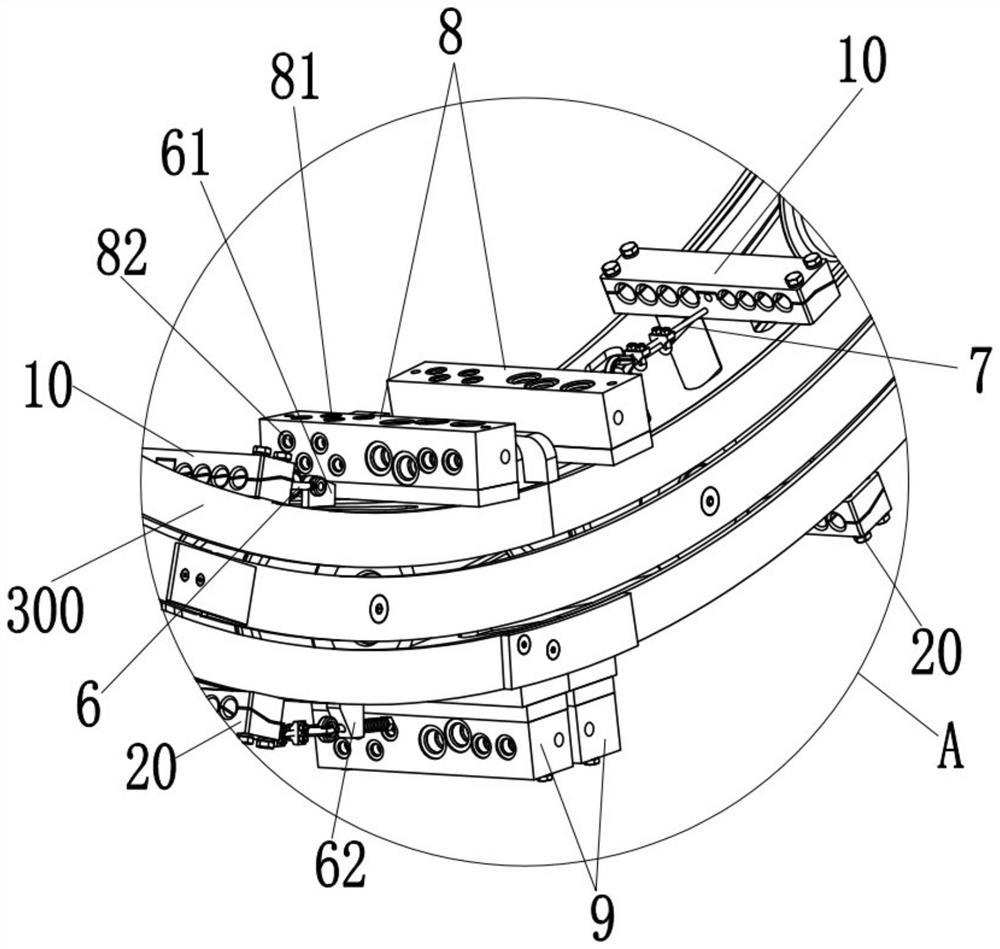

[0070] In order to better explain the present invention, in order to understand, the following combined with the attached drawings, through the specific embodiment, the present invention is described in detail. Among them, the "upper", "lower", "left", "right", "front" and "back" mentioned in this article are based figure 1 The orientation is for reference. figure 1 The medium -connected guide strip 13 is defined as the "rear" side on one side of the outer circle 1.

[0071] An embodiment proposed by the invention embodiment to the hose pipeline wrap device for the pipe assembly machine is connected to the pipeline assembly machine. Under the premise of the hydraulic pumping station on the shield machine building, the hose pipeline wrap device to ensure that the hydraulic pump stitching the hydraulic oil cylinder provides power while the hydraulic oil cylinder and the wire 600 of the hydraulic oil cylinder will not be broken Essence See Figure 1-Figure 3 It shows that the hoses of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com