Straight-through type vacuum glass solar heat collecting tube

A solar collector tube and vacuum glass technology, which is applied to solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of increasing intelligence, inconsistent positioning of inner and outer tubes, and inconsistent positioning, to avoid Difficult to fix, ensure stability, and achieve uniform positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

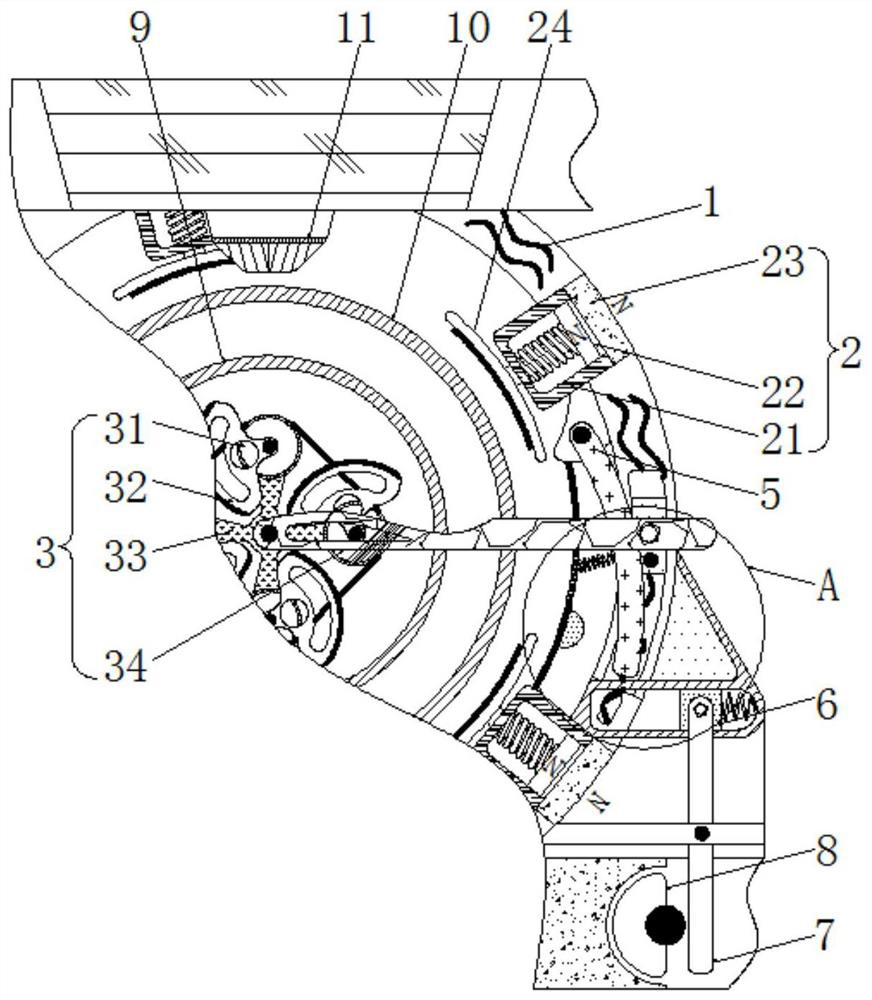

[0026] see figure 1 , a straight-through vacuum glass solar collector tube, comprising an outer tube limiting mechanism 2, the outer tube limiting mechanism 2 includes a fixed frame 21, the inside of the fixed frame 21 is provided with a cavity, and the size of the cavity is the same as that of the electromagnet 22 The size of the electromagnet 22 is adapted to each other, and the magnetism generated by the electromagnet 22 is the same as the magnetic pole of the fixed magnet 23, so that the electromagnet 22 can move along the cavity provided inside the fixed frame 21 to ensure the stability when moving. The movement of the electromagnet 22 drives the outer brake plate 24 to move synchronously. The interior of the fixed frame 21 is clamped with the electromagnet 22. The bottom end of the fixed frame 21 is welded with a fixed magnet 23. The end of the electromagnet 22 away from the fixed magnet 23 is engaged There are outer brake plates 24, and the number of outer brake plates ...

Embodiment 2

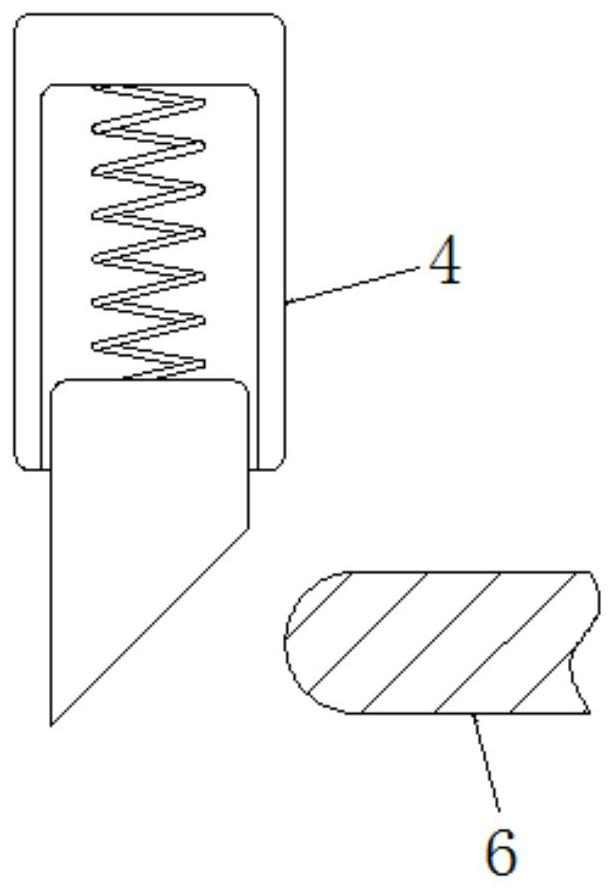

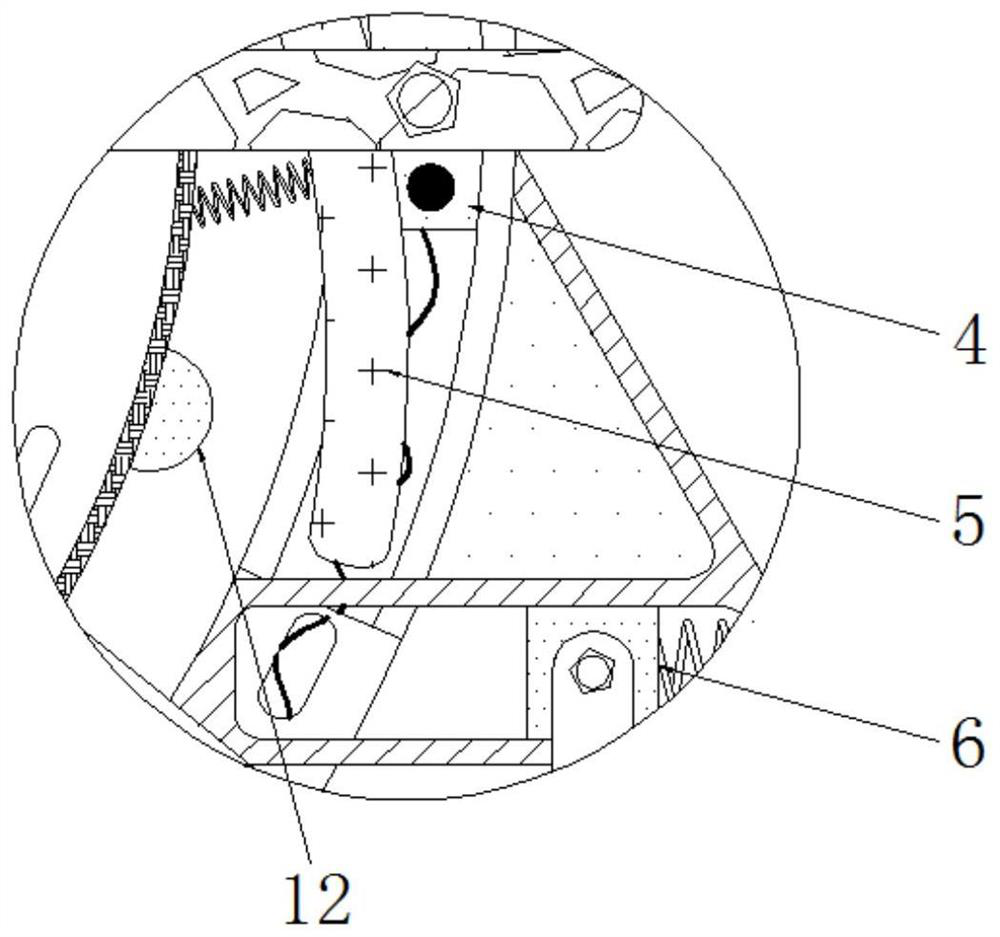

[0029] see figure 1 , a straight-through vacuum glass solar collector tube, including an inner tube limit mechanism 3, an inner brake plate 31 is rotatably connected to the inner end of the outer brake plate 24, and an inner brake plate 32 is rotatably connected to the surface of the disc 31, and the inner brake plate 32 is used to rotate the inner end of the outer brake plate 24. The swing of the brake plate 32 simultaneously limits the position of the inner tube 9 to ensure the stability of the inner tube 9. The back of the disc 31 is clamped with a connecting plate 33, and the movement of the connecting plate 33 drives the disc 31 to rotate synchronously. , the surface of the connecting plate 33 is rotatably connected with a handle 34, the movement of the handle 34 drives the connecting plate 33 to move synchronously, the back of the outer tube limit mechanism 2 is fixedly connected to the support seat 1, and the support seat 1 is internally clamped with a moving block 4, T...

Embodiment 3

[0032] see Figure 1-3, a straight-through vacuum glass solar collector tube, comprising an outer tube limiting mechanism 2, the outer tube limiting mechanism 2 includes a fixed frame 21, the inside of the fixed frame 21 is provided with a cavity, and the size of the cavity is the same as that of the electromagnet 22 The size of the electromagnet 22 is adapted to each other, and the magnetism generated by the electromagnet 22 is the same as the magnetic pole of the fixed magnet 23, so that the electromagnet 22 can move along the cavity provided inside the fixed frame 21 to ensure the stability when moving. The movement of the electromagnet 22 drives the outer brake plate 24 to move synchronously. The interior of the fixed frame 21 is clamped with the electromagnet 22. The bottom end of the fixed frame 21 is welded with a fixed magnet 23. The end of the electromagnet 22 away from the fixed magnet 23 is engaged There are outer brake plates 24, and the number of outer brake plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com