Nondestructive testing method for metal laser strengthening surface

A non-destructive testing and laser-enhanced technology, applied in the field of testing, can solve the problems of missing defects, insufficient accuracy, low efficiency, etc., and achieve the effect of comprehensive testing range, high accuracy and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

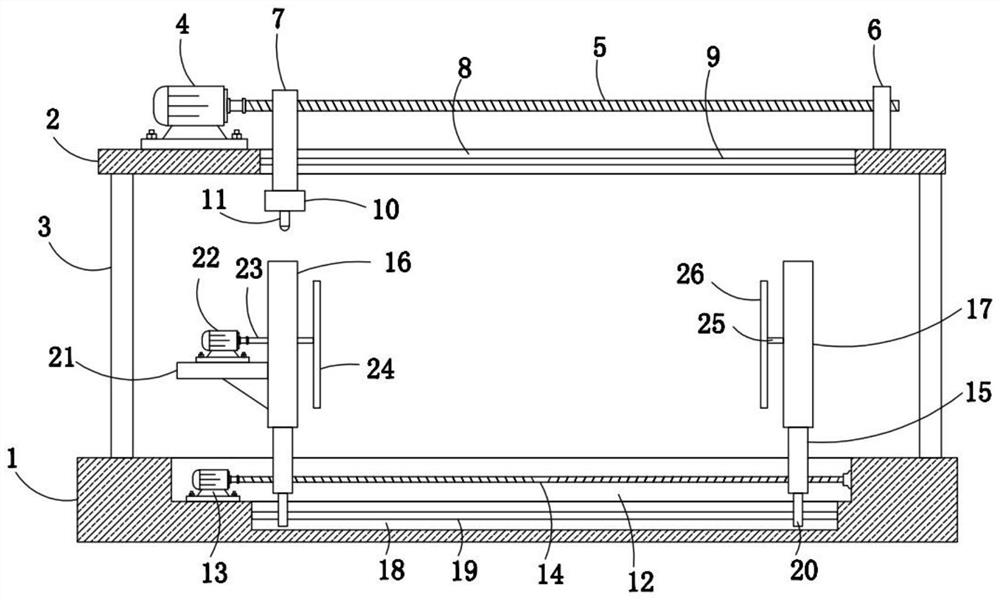

[0027] Please refer to figure 1 , figure 1 It is a schematic diagram of the structure of the ultrasonic flaw detection device for the metal laser strengthening surface non-destructive testing method provided by the present invention. The non-destructive testing method for metal laser strengthened surface includes the following steps:

[0028] S1: Clean the surface of the metal;

[0029] S2: Coating an alloy light-absorbing coating on the cleaned metal surface;

[0030] S3: After the alloy light-absorbing coating is dried, performing laser solution treatment on the metal;

[0031] S4: cooling the metal after laser solution treatment;

[0032] S5: performing aging treatment on the metal after cooling treatment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com