Substrate, applicable manufacturing method thereof, and power module

A manufacturing method and substrate technology, which are applied in the direction of output power conversion device, inductor/transformer/magnet manufacturing, conversion of DC power input to DC power output, etc., can solve the problem that high efficiency, high power density and high heat dissipation capacity cannot be further achieved and other problems to achieve the effect of solving electromagnetic interference, reducing connection impedance, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] Some typical embodiments embodying the features and advantages of the present disclosure will be described in detail in the description in the following paragraphs. It should be understood that the disclosure is capable of various changes in different embodiments without departing from the scope of the disclosure, and that the description and drawings therein are illustrative in nature and not limiting. This disclosure.

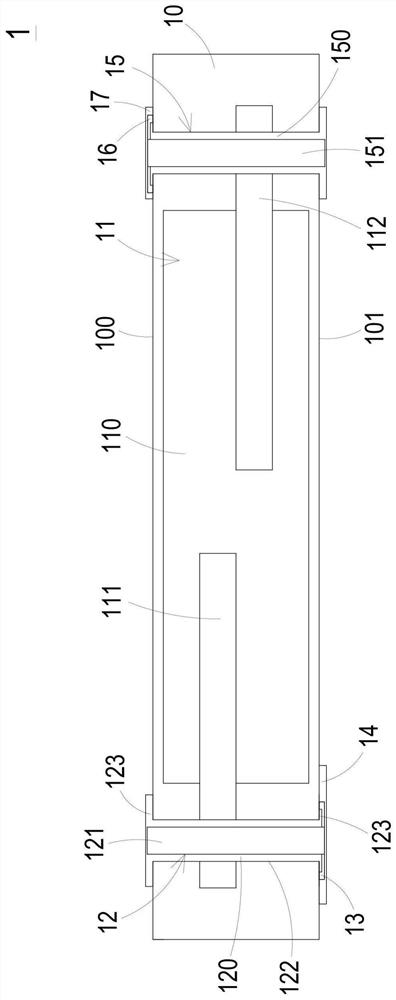

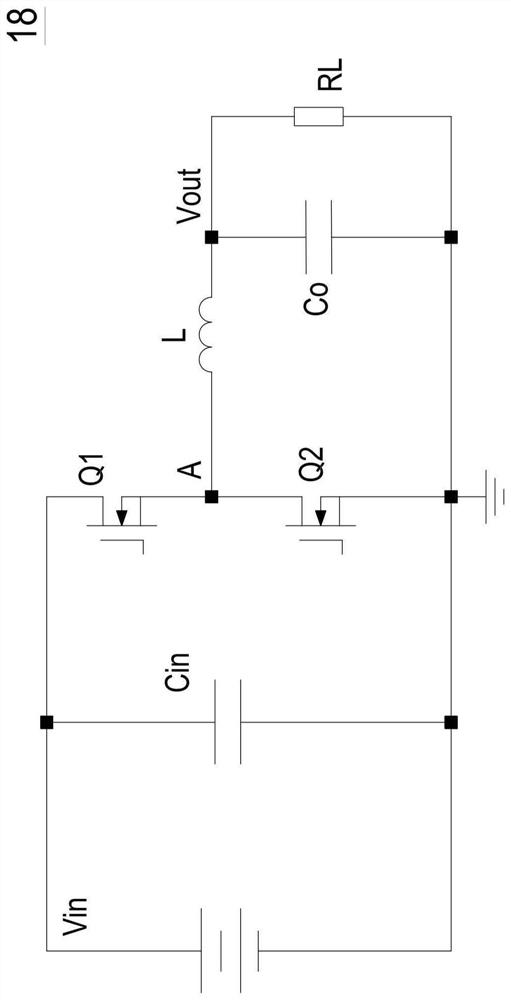

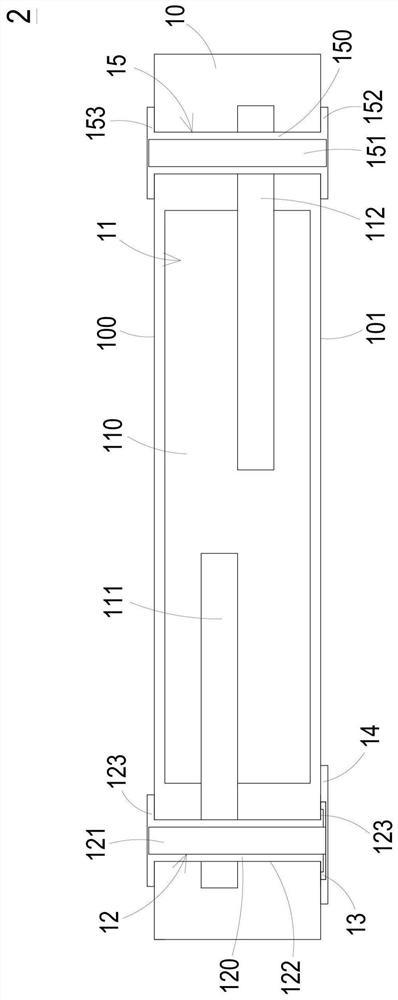

[0115] The inventive concept of the present disclosure is a substrate including a first insulating layer, at least one passive element, at least a first through hole, a second insulating layer and a second electrode. The first insulating layer includes an upper surface and a lower surface. The passive element is embedded in the first insulating layer and has a first conducting terminal. The first through hole is formed in the first insulating layer adjacent to one side of the passive element and penetrates the first insulating layer, wherein the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com