Ditching machine capable of freely moving and offsetting

A ditching machine and mobile frame technology, applied in the field of agricultural tools, can solve the problems of affecting the ditching effect, narrow adaptation range, and inability to adjust, so as to achieve the effect of improving regional adaptability, reasonable structural design, and ensuring ditching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

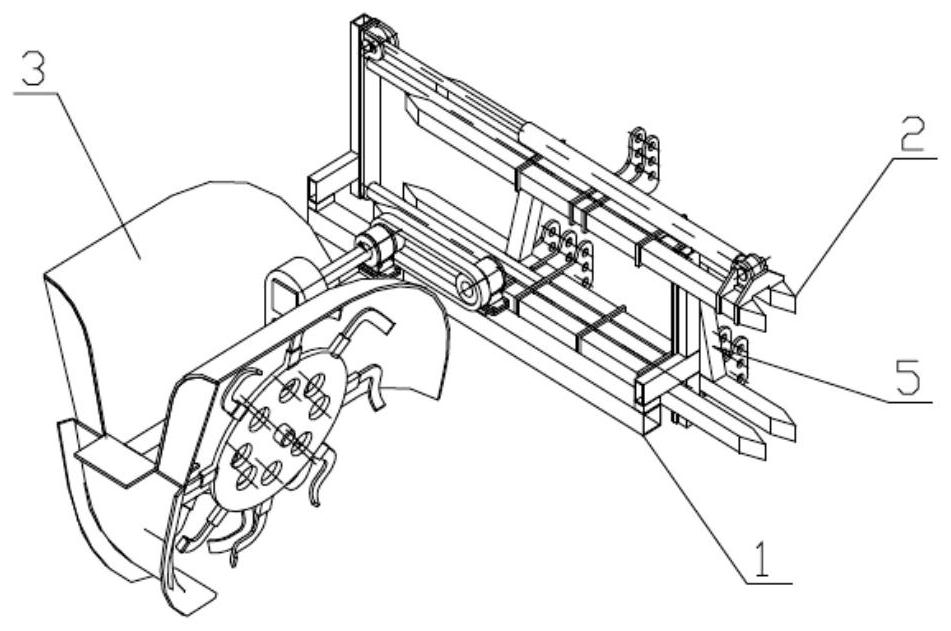

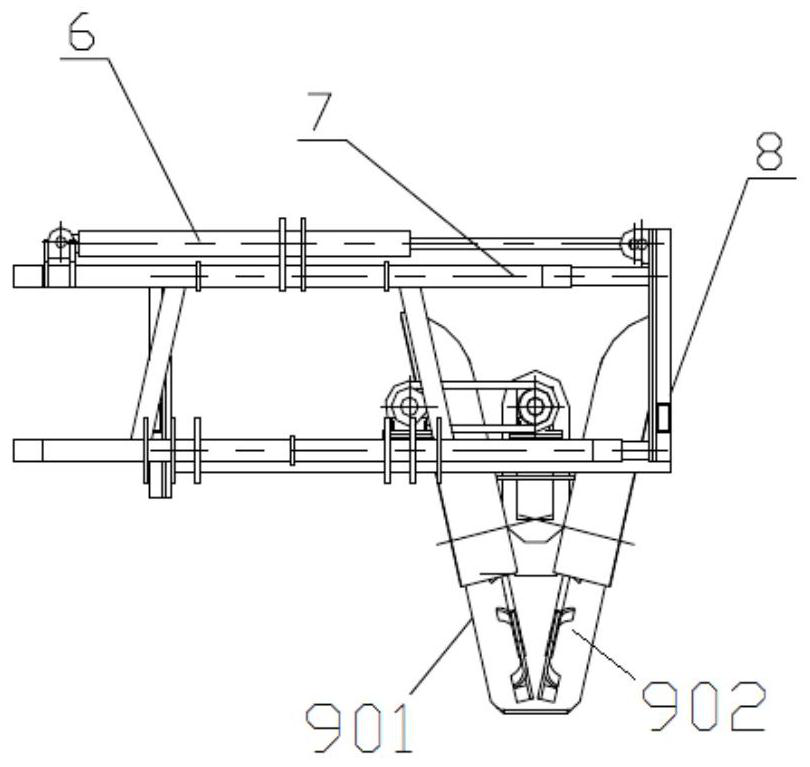

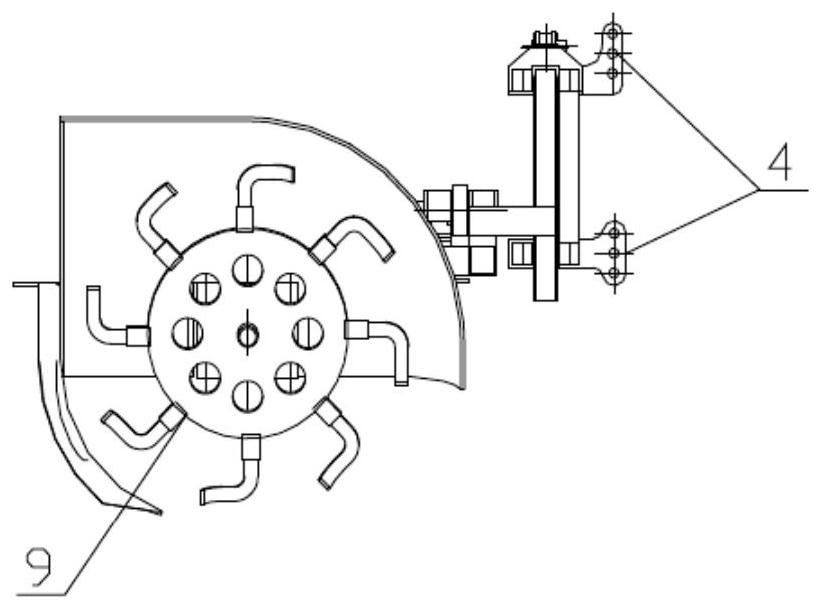

[0034] The free-moving offset trencher mainly includes three parts: fixed traction frame, moving mechanism and opener.

[0035] 1. The fixed traction frame is mainly used for the connection between the overall device and the power machine. It is equipped with a standard three-point suspension point, which can be suspended with the power machine; and a fixed support frame is set on the fixed traction frame as a support for the fixed end or part of the mobile mechanism. .

[0036] 2. The moving mechanism is mainly used to drive the ditching equipment to move freely. It is mainly composed of a telescopic hydraulic cylinder, a moving sleeve and a moving frame. The cylinder barrel of the telescopic hydraulic cylinder is fixed on the fixed support frame of the fixed traction frame, and the telescopic rod is fixed on the mobile frame, and the hydraulic system of the power machine is used to drive the telescopic rod of the telescopic hydraulic cylinder to move back and forth; the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com