A threshing drum applied to edible bean threshing equipment

A threshing drum and equipment technology, applied in threshing equipment, application, agriculture, etc., can solve the problems that it is difficult to adapt to multi-variety bean pods, high bean damage rate, and difficult to adjust the gap between the nail teeth and the inner wall of the sieve plate threshing chamber, so as to reduce crushing rate, improve the effect of threshing, and the effect of uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

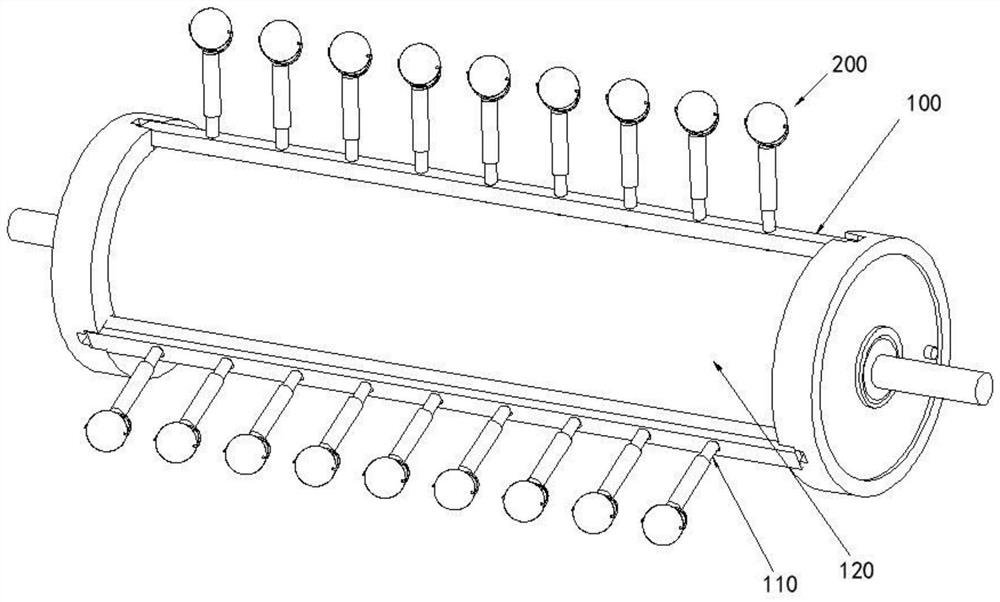

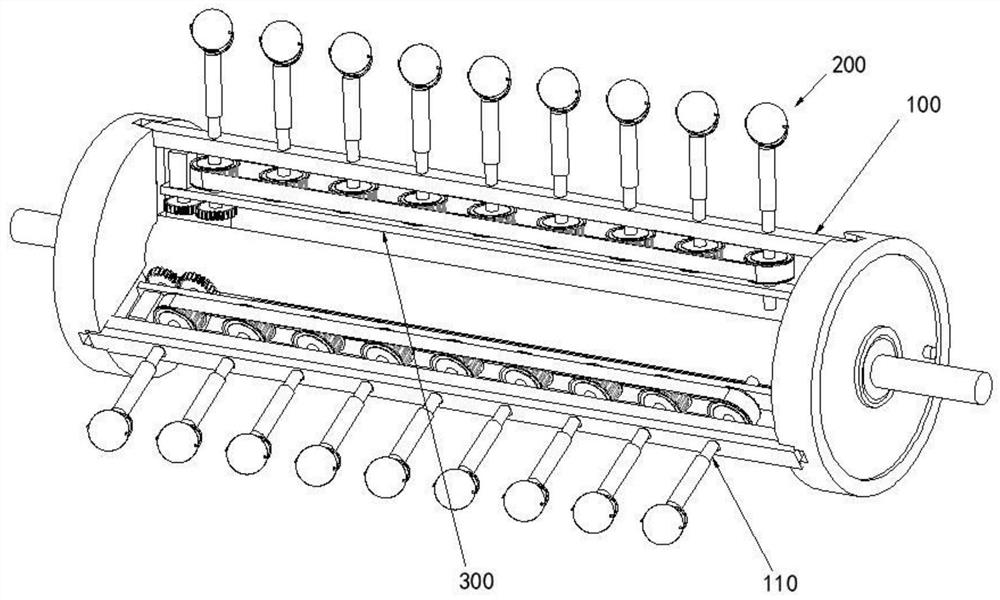

[0027] Such as Figure 1 to Figure 4 As shown, the threshing drum applied to edible bean threshing equipment in this embodiment includes a drum 100, a spike assembly 200 and an adjustment assembly 300;

[0028] Three rows of mounting rods 110 are arranged on the surface of the drum 100;

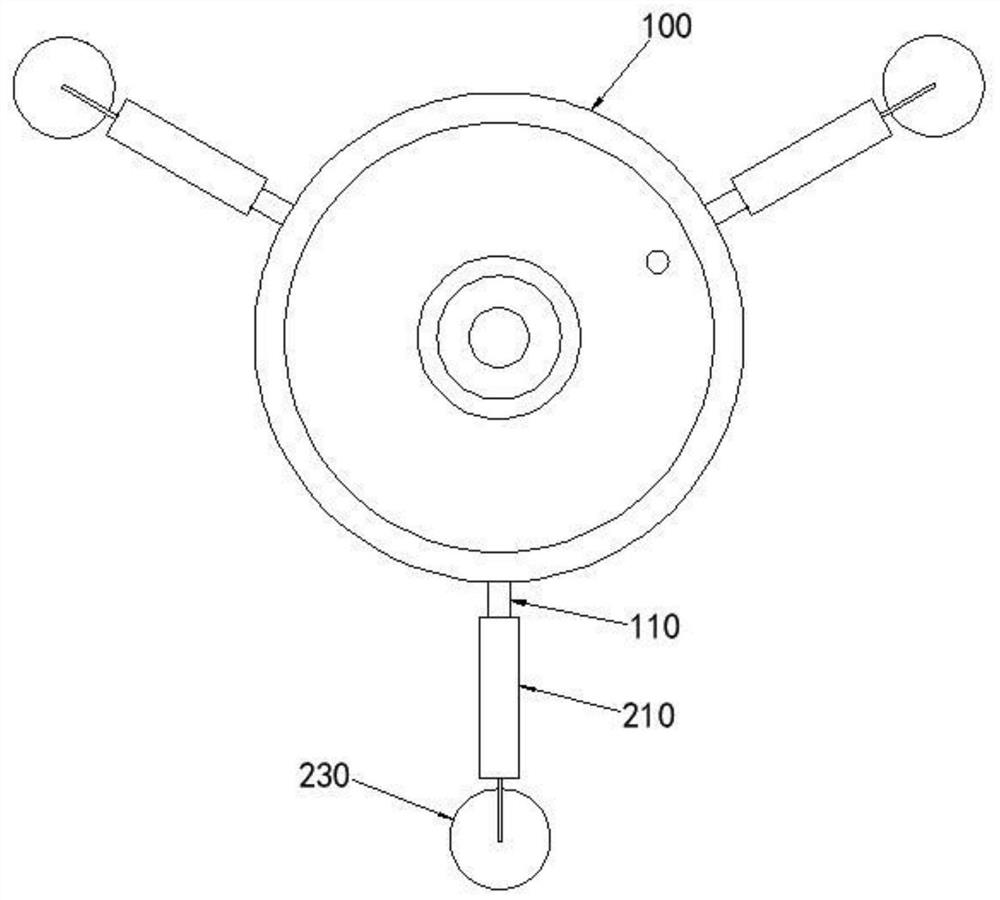

[0029] The nail-tooth assembly 200 includes a fixed rod 210, a rotating shaft 220 and a ball 230. The ball 230 is mounted on one end of the fixed rod 210 through the rotating shaft 220. The ball 230 can rotate around the rotating shaft 220. The rotating shaft 220 is parallel to the central axis of the drum 100. The fixed rod 210 Connect with the mounting rod 110;

[0030] The adjustment assembly 300 includes a mounting plate 310, a motor 320, a second gear set 330, a synchronous pulley 340 and a belt 350, and the mounting rod 110 is screwed to the drum 100, and all the mounting rods 110 are equipped with a synchronous pulley 340, the same row The synchronous pulley 340 on the mounting bar 1...

Embodiment 2

[0034] Such as Figure 5 to Figure 9 As shown, the difference between this embodiment and Embodiment 1 lies in the nail-tooth assembly 200. The nail-tooth assembly 200 in this embodiment includes a fixed rod 210, a housing 240, a first gear set 250, a first cylinder 260, a second Two cylinders 270, the first rotating shaft 280 and the second rotating shaft 290, the housing 240 is connected with the fixed rod 210, the two ends of the first cylinder 260 are connected to the housing 240 through the first rotating shaft 280, the two ends of the second cylinder 270 The housing 240 is connected through the second shaft 290, the first cylinder 260 is parallel to the second cylinder 270; the first gear set 250 is located in the housing 240, and the first gear set 250 is connected to the first shaft 280 and the second shaft 290, The surface of the first cylinder 260 is provided with transverse lines, and the distance between the outer edge of the first cylinder 260 and the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com