Fiber bar stock sorting mechanism

A technology for finishing mechanisms and fiber rods, which is applied in packaging and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

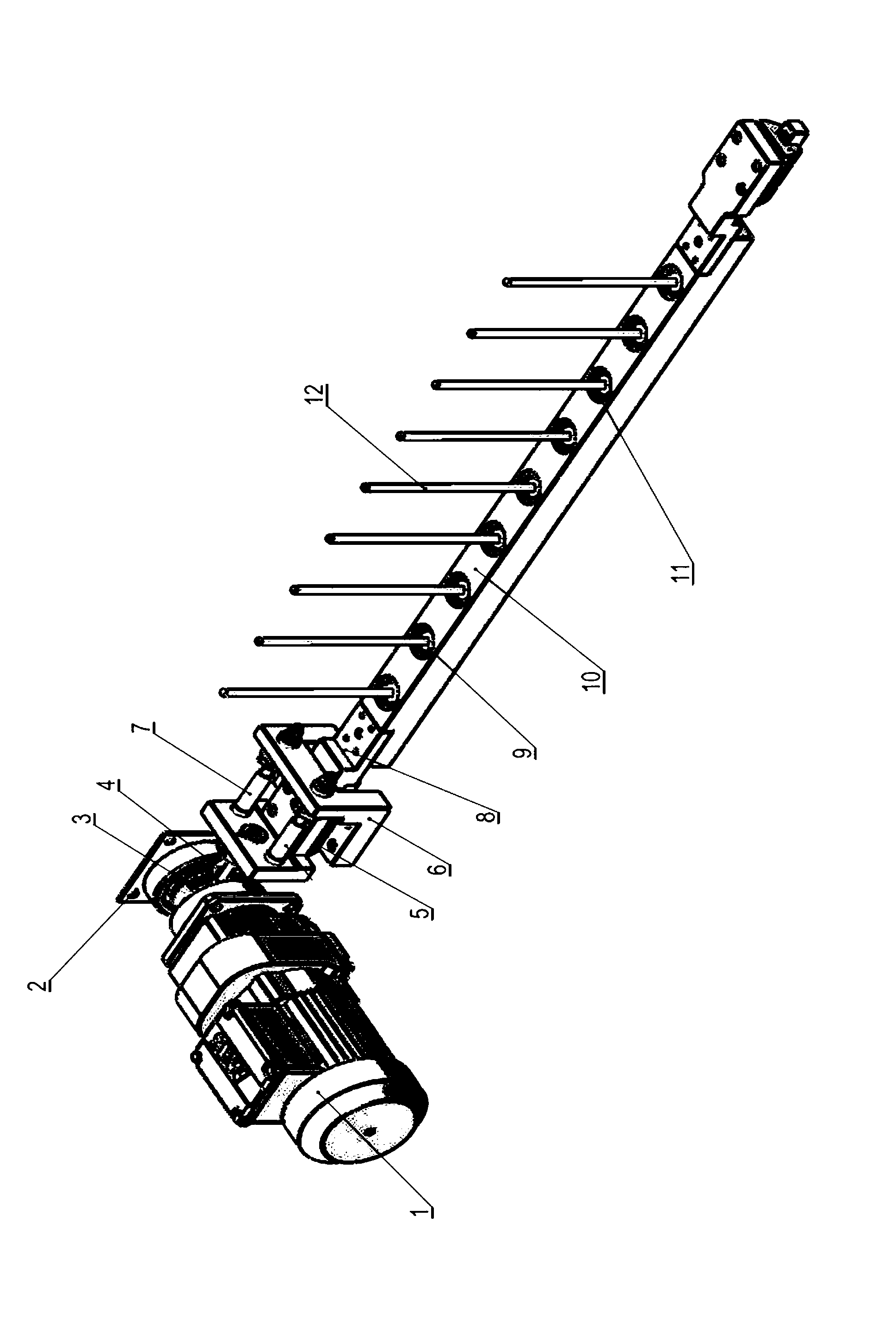

[0014] Depend on figure 1 It can be seen that the fiber bar finishing mechanism is mainly composed of a geared motor 1, a swing bearing 4, and a base plate 10. The geared motor 1 is provided with a motor connection seat 2 and a cam 3, and the geared motor 1 and the base plate 10 are connected through the swing bearing 4. , The two ends of the substrate 10 are provided with connecting blocks 8, wherein, the substrate 10 is also provided with a bearing 11, the bearing 11 is provided with a clamping block 9, and the clamping block 9 is provided with a finishing shaft 12.

[0015] Depend on figure 1 It can also be seen that the connecting block 8 is provided with a slide rail 5 , and the slide rail 5 is provided with a spring fixing member 6 .

[0016] Depend on figure 1 It can also be seen that a spring guide shaft 7 is provided on the spring fixing member 6 .

[0017] When working, the deceleration motor drives the cam to rotate, and the radius of the tangent point between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com