Anti-overflow system of base station and base station

An anti-overflow and base station technology, which is applied in the anti-overflow system of the base station and in the field of base stations, can solve the problems of no anti-overflow function and easy overflow, and achieve good anti-overflow effect, clean and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

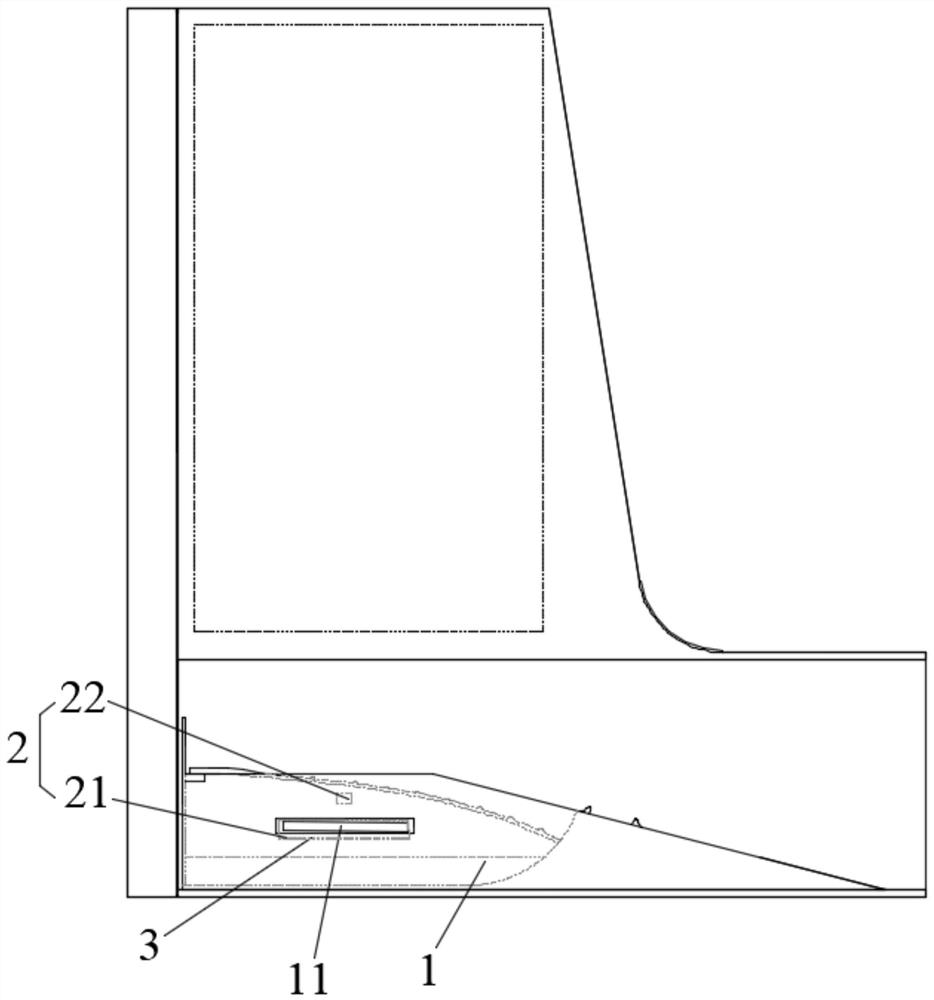

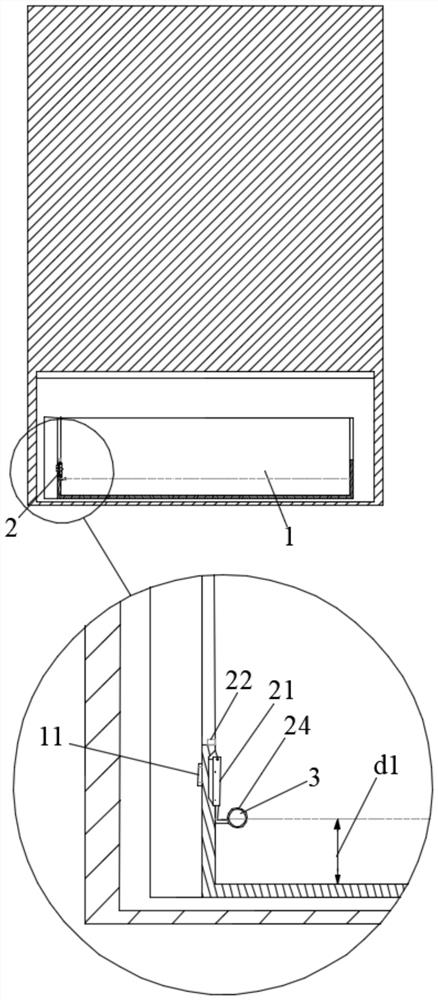

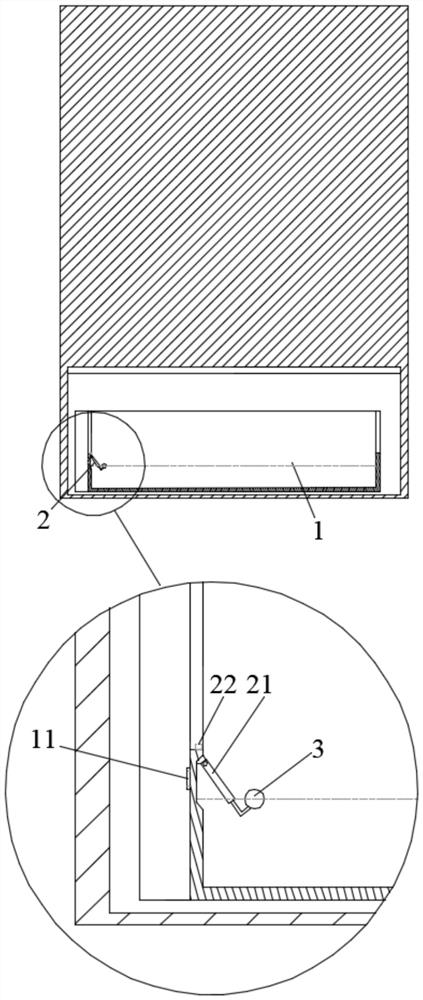

[0055] Such as figure 1 and figure 2 as shown, figure 1 is a side view of the overflow prevention system of the base station of the present invention, figure 2 is a schematic diagram of the reaction element in the first state.

[0056] The anti-overflow system of the base station of the present invention can be applied to the liquid storage tank 1, wherein:

[0057] The base station is applicable to the cleaning robot 4, can be used to clean the mopping parts of the cleaning robot 4, and can charge the cleaning robot 4 or / and clean the mopping parts and other maintenance work.

[0058] The liquid storage tank 1 may be a tank for storing clean water, cleaning agent, sewage or other liquids produced after cleaning, and it may be an open tank with a top opening or other openings, or a closed tank. For example, it can be a cleaning tank used to clean the mopping parts of the cleaning robot 4. After the cleaning robot 4 enters the cleaning tank, the sewage generated after cle...

Embodiment 2

[0108] Such as Figure 12 as shown, Figure 12 It is a structural schematic diagram of the base station of the present invention.

[0109] The present invention further provides a base station for cleaning the mopping parts of the cleaning robot 4, including the overflow prevention system of the base station in the above embodiment, and the liquid storage tank 1 is the sewage collection tank in the above embodiment.

[0110] The base station of the present invention can be applied to the cleaning robot 4, and the base station can be used for charging the cleaning robot 4 or / and cleaning the mopping parts of the cleaning robot 4, as follows:

[0111] The cleaning method of the base station for the cleaning robot 4 may be water washing, specifically, mechanical friction water washing, or ultrasonic water washing.

[0112] The cleaning robot 4 can be a commercial cleaning robot and a household cleaning robot according to its purpose, and can be an automatic cleaning robot such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com