Three-dimensional printing method and device, computer equipment and storage medium

A 3D printing and 3D model technology, which is used in manufacturing auxiliary devices, processing and manufacturing, and processing data acquisition/processing. demand, the effect of improving the smoothness and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

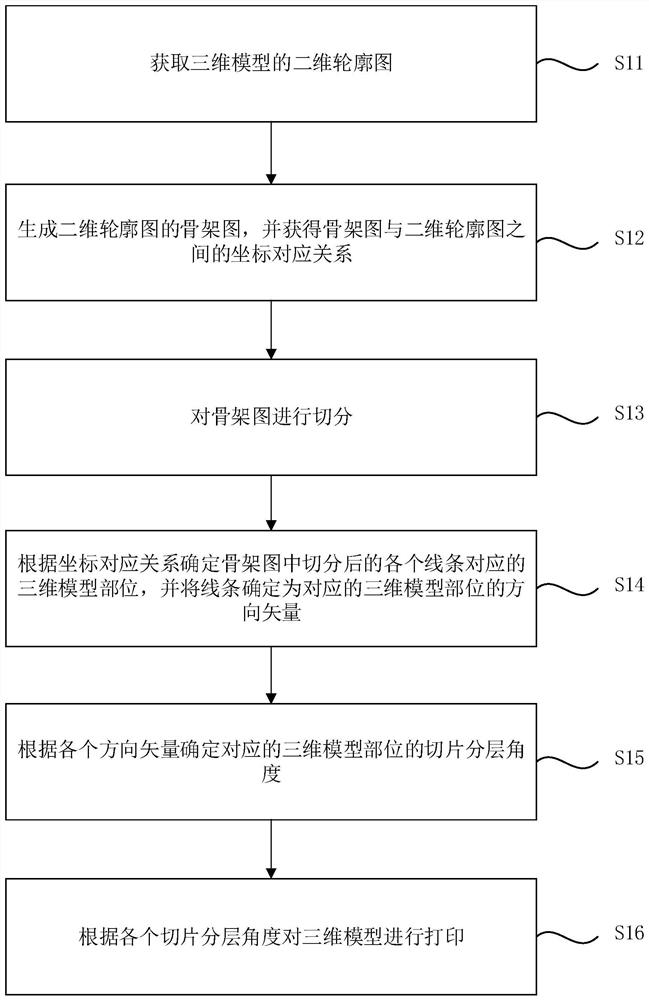

[0048] figure 1 It is a flow chart of the three-dimensional printing method provided by Embodiment 1 of the present invention. This embodiment is applicable to the case of printing a three-dimensional model using fused deposition modeling technology. This method can be executed by the three-dimensional printing device provided by the embodiment of the present invention. The device can be implemented by hardware and / or software, and generally can be integrated in computer equipment. Such as figure 1 As shown, it specifically includes the following steps:

[0049] S11. Obtain a two-dimensional contour map of the three-dimensional model.

[0050] Among them, the two-dimensional contour map can be obtained by projecting the three-dimensional model from any direction, and further, the projection map with the largest area in the projection map obtained by projecting in any direction can be determined as the two-dimensional contour map of the three-dimensional model in this scheme...

Embodiment 2

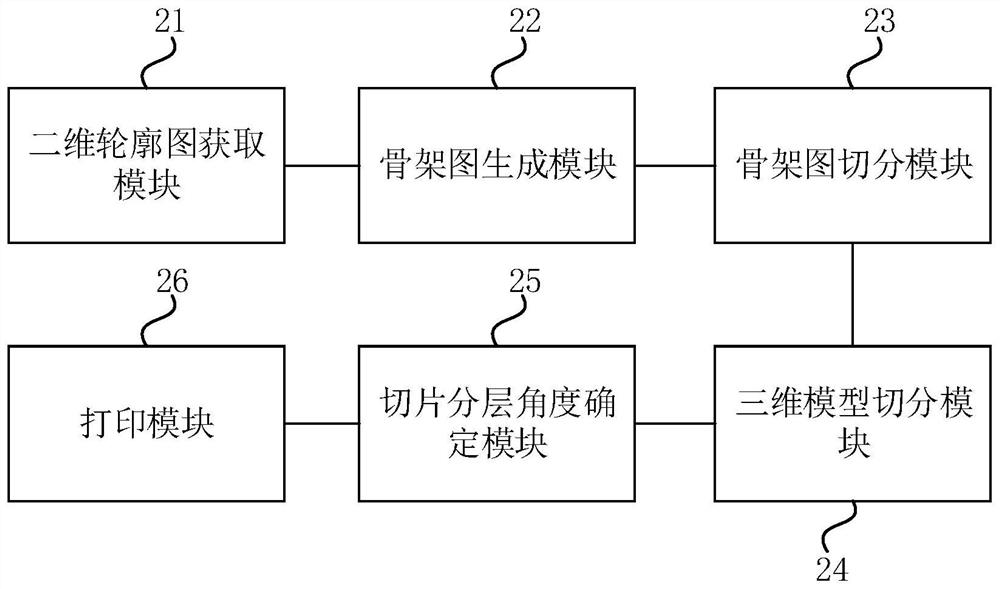

[0065] figure 2 It is a schematic diagram of the structure of the 3D printing device provided in Embodiment 2 of the present invention. The device can be implemented by hardware and / or software, and generally can be integrated into computer equipment. Such as figure 2 As shown, the device includes:

[0066] A two-dimensional contour map acquisition module 21, configured to obtain a two-dimensional contour map of a three-dimensional model;

[0067] A skeleton diagram generating module 22, configured to generate a skeleton diagram of a two-dimensional contour diagram, and obtain a coordinate correspondence between the skeleton diagram and the two-dimensional contour diagram;

[0068] Skeleton graph segmentation module 23, used to segment the skeleton graph;

[0069] The three-dimensional model segmentation module 24 is used to determine the corresponding three-dimensional model position of each line after the segmentation in the skeleton diagram according to the coordinate ...

Embodiment 3

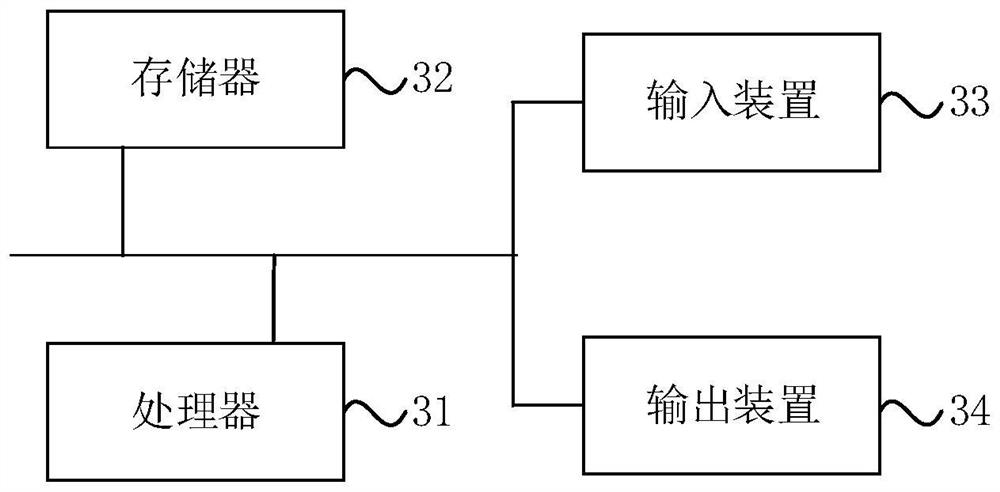

[0088] image 3 The schematic structural diagram of the computer device provided for the third embodiment of the present invention shows a block diagram of an exemplary computer device suitable for implementing the embodiment of the present invention. image 3 The computer equipment shown is only an example, and should not bring any limitation to the functions and scope of use of the embodiments of the present invention. Such as image 3 As shown, the computer equipment includes a processor 31, a memory 32, an input device 33 and an output device 34; the number of processors 31 in the computer equipment can be one or more, image 3 Taking a processor 31 as an example, the processor 31, memory 32, input device 33 and output device 34 in the computer equipment can be connected by bus or other methods, image 3 Take connection via bus as an example.

[0089] The memory 32, as a computer-readable storage medium, can be used to store software programs, computer-executable progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com