Multi-mode dual-motor coupling electric drive axle

A technology of electric drive and dual motors, which is applied in the direction of electric power device, power device, rolling resistance optimization, etc., can solve the problems of little research and application, and achieve the effects of small resonance risk, improved power performance and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0065] An embodiment of the multi-mode dual-motor coupling electric drive axle according to the present invention is given below in conjunction with the accompanying drawings.

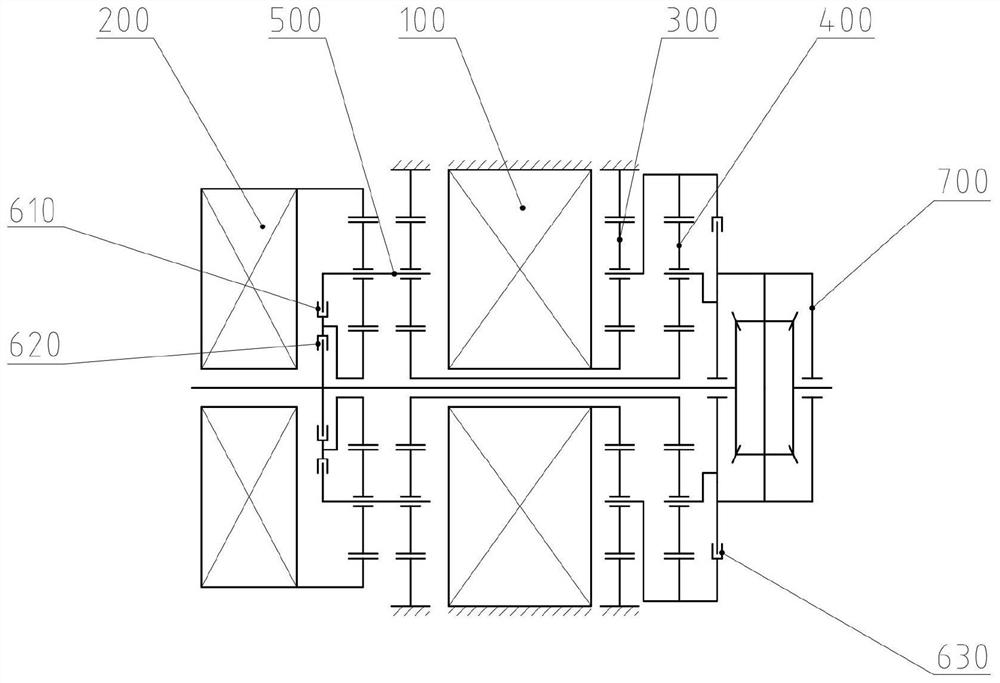

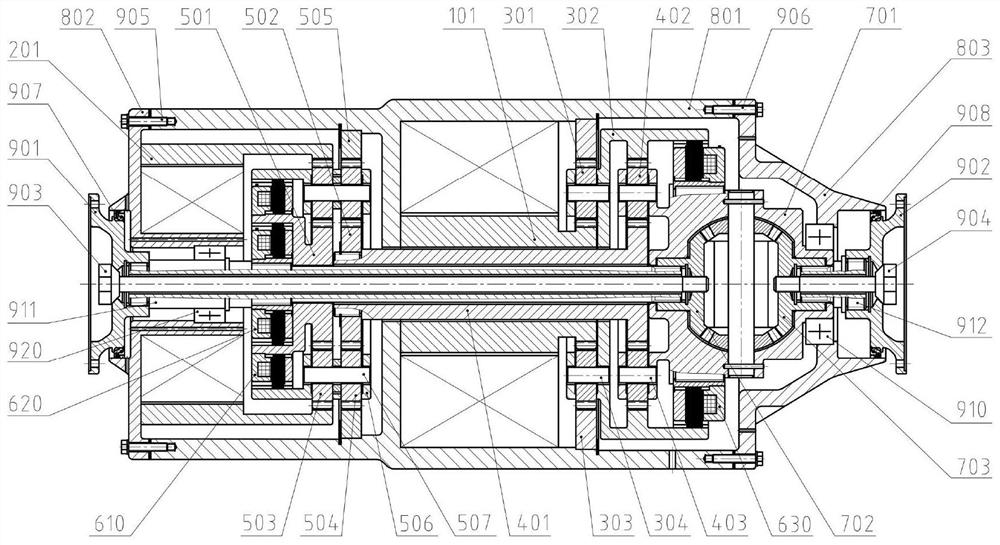

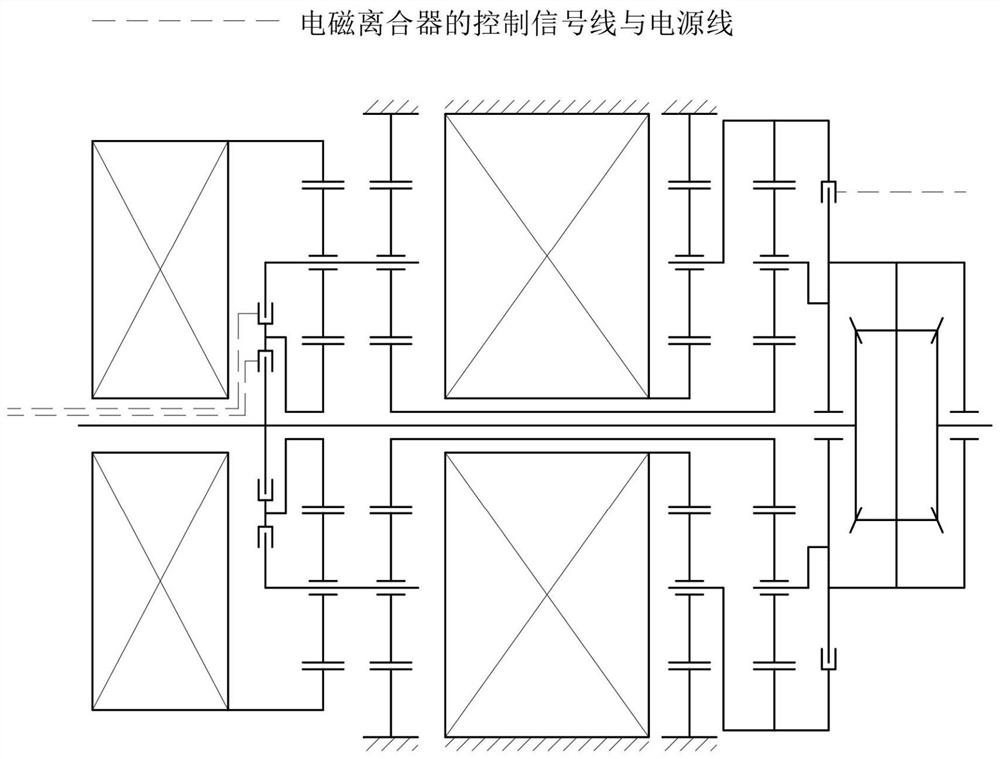

[0066] Such as figure 1 , figure 2 As shown, a multi-mode dual-motor coupling electric drive axle mainly consists of a main motor 100, an auxiliary motor 200, a differential 700, a first half shaft 911, a second half shaft 912, a housing 801, a front cover 802, a rear End cover 803, first flange 901, second flange 902, final reducer 300, power coupling mechanism 400, TV coupling mechanism 500, first clutch 610, second clutch 620, third clutch 630 and so on.

[0067] The main motor 100 is a hollow-shaft inner-rotor permanent magnet synchronous motor, arranged on the left side of the differential 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com