Hanging clothes sorting robot, system and method

A sorting system and robot technology, applied in conveyors, mechanical conveyors, storage devices, etc., can solve the problems of low degree of automation, slow efficiency and high error rate, and achieve the effect of saving labor costs and high sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

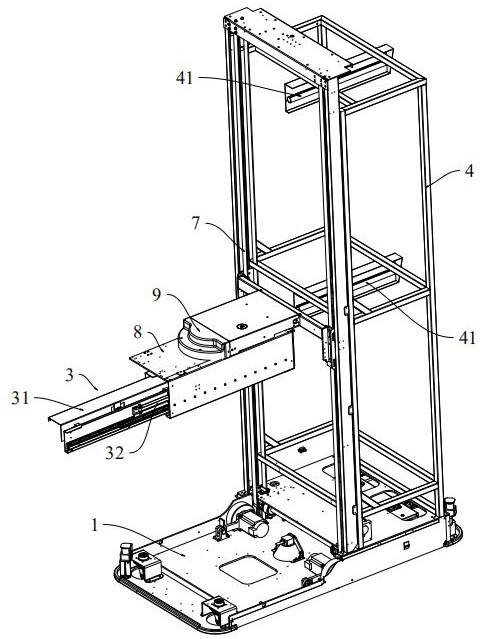

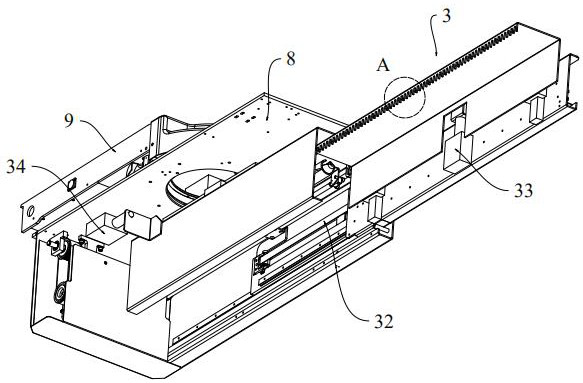

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

[0062] The hanging clothing mentioned in the present invention is clothing with a hanger (a hanger in the form of a hook).

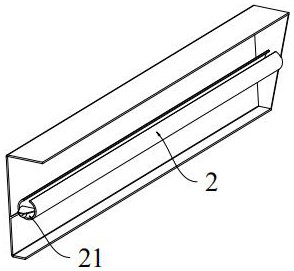

[0063] as attached figure 1 with attached Figure 6The hanging clothing sorting robot shown (hereinafter referred to as the sorting robot for short) includes a mobile seat 1, a temporary hanger 2 and a clothing transfer mechanism 3; wherein the mobile seat 1 can move controllably, The form of the mobile seat 1 can be a movable structure such as a wheeled mobile chassis or a shuttle car. In this embodiment, the mobile seat 1 is a six-wheel robot chassis, which includes two driving wheels and four driven wheels. On both sides of the middle part of the chassis, four driven wheels are located at the four corners of the chassis; hanging clothes can be stored on the temporary hanger 2, which is used for temporary storage of hanging clothes, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com