A preparation method of modified biochar for improving heavy metal pollution

A heavy metal and biochar technology, applied in the preparation/purification of carbon, energy input, etc., can solve problems such as reducing soil environmental risks, and achieve the effect of promoting effective absorption or enrichment, reducing content, and reducing potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present inventors also found that an appropriate amount of iron can improve the effectiveness of lead and promote the accumulation of lead in plants such as cattails.

Therefore, described chelating agent preferably contains the chelating agent of iron, for example iron ethylenediaminetetraacetate (Fe-EDTA), diethylene

Ferric triaminepentaacetate (Fe-DTPA), ethylenediamine ferric ortho-dihydroxyacetate (Fe-EDDHA), more preferably Fe-EDTA. Among them, Fe-

EDTA has stable chemical properties and is easily soluble in water. EDTA surrounds metal iron ions in space hexahedrons, and has excellent chelating properties.

combined effect.

According to the present invention, the concentration of described Fe-DTPA iron element is 30~200mg / L, preferably 50~100mg / L, more

Preferably it is 60-70 mg / L.

According to the present invention, in artificial wetland, inoculate microorganism, described microorganism is compound bacteria, promotes the growth of plant,

And increase...

Embodiment 1

The liquid was poured out, the zeolite was washed with deionized water for 3 times, dried at 100 °C for 3 hours, and then calcined at 500 °C for 1.5 hours.

A modified zeolite is obtained.

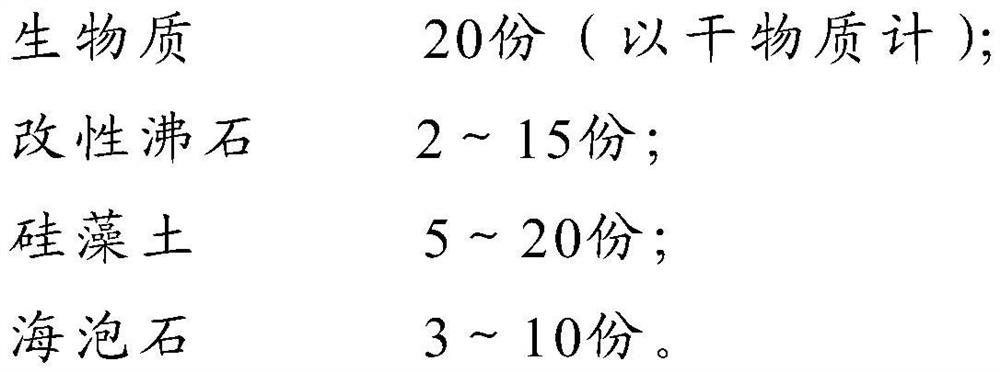

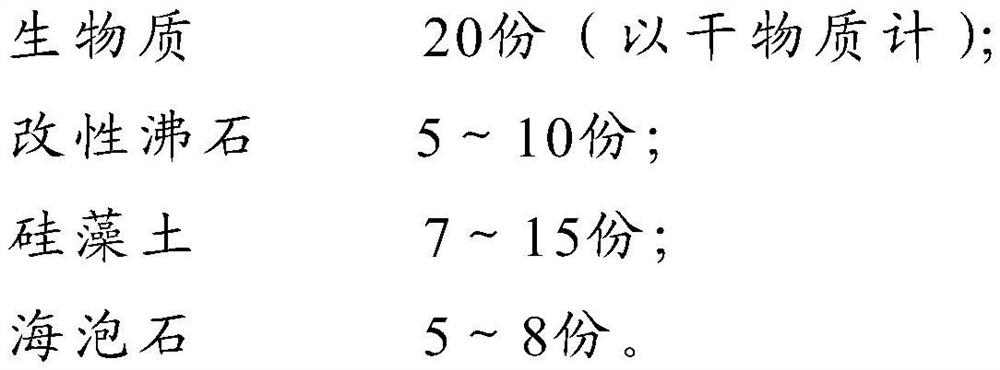

(3) biomass, modified zeolite, diatomite and sepiolite are carried out as follows by following weight portion:

[0081]

[0082]

The sepiolite that particle diameter is 3mm is added in the diatomite with moisture content of 55%, stirs 12h, adds to it again

Biomass, continue to stir for 16h, and finally add modified zeolite to the system, stir for 6h, and keep the system at 70°C

3h, grind into powder and pass through a 110-mesh sieve.

Above-mentioned powder is calcined according to the following procedure to obtain modified biochar:

The first stage: calcination temperature 280 ℃, holding time 2.5h, heating rate 4 ℃ / min;

Second stage: calcination temperature 460 ℃, holding time 1.5h, heating rate 6 ℃ / min;

[0087] The third stage: the calcination temperature is 570° C., the holding t...

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com