Cement mortar and preparation method thereof

A technology of cement mortar and ordinary Portland cement, applied in the field of building materials, can solve the problems of not paying attention to the stability of mortar, and achieve the effects of improving stability and water retention performance, low degree of separation, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

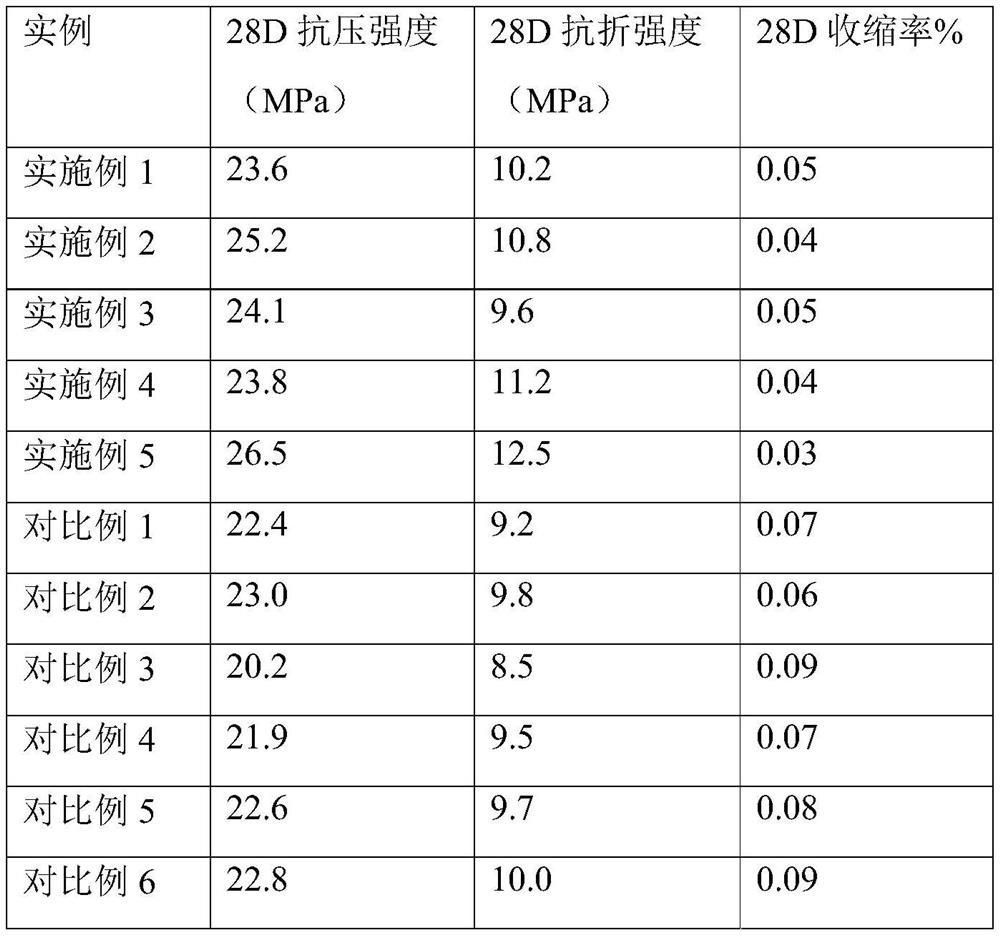

Examples

preparation example Construction

[0046] Basic Example A kind of preparation method of titanium gypsum

[0047] Include the following steps:

[0048] (1) Collect titanium dioxide acidic wastewater and transfer it to the adjustment tank to mix evenly, transfer the uniformly mixed titanium dioxide acidic wastewater and crystal seeds to the primary neutralization tank and add calcium carbonate for primary neutralization, and adjust the pH to 3- 4. Obtain a primary neutralizing solution;

[0049] (2) the first-level neutralization solution obtained in step (1) is transferred to the second-level neutralization pool, and calcium hydroxide is added to carry out the second-level neutralization, and the pH adjustment is 7-9 to obtain the second-level neutralization solution;

[0050] (3) transfer the secondary neutralization solution obtained in the step (2) into the aeration tank to add polyacrylamide, and fill it with compressed air to obtain mixture A;

[0051] (4) The mixture A is transferred to the thickening ta...

Embodiment 1

[0053] Embodiment 1 A kind of cement mortar

[0054] It includes the following components by weight: 10% ordinary Portland cement, 10% fly ash, 40% quartz sand, 5% calcium lignosulfonate, alkyl trimethyl quaternary ammonium alkyl trimethyl 1% quaternary ammonium salt, 4% bentonite, 4% titanium gypsum and the balance water.

[0055] Described fly ash is:

[0056] 30-50μm 10%;

[0057] 60-100μm 90%;

[0058] Described titanium gypsum is prepared by the method of basic embodiment, and in titanium gypsum, CaSO 4 2H 2 The content of O is 80.6%.

[0059] The preparation method comprises the following steps:

[0060] S1, calcium lignosulfonate, alkyl trimethyl quaternary ammonium salt, bentonite, titanium gypsum and 20% of the formula amount of water are mixed, stirred evenly, to obtain the mixture M;

[0061] S2. Add ordinary Portland cement, fly ash, quartz sand and the remaining amount of water to the mixture M obtained in step S1 and stir evenly to obtain the cement mortar...

Embodiment 2

[0062] Embodiment 2 A kind of cement mortar

[0063] The following components are included in parts by weight: ordinary portland cement 20%, fly ash 15%, quartz sand 60%, sodium lignosulfonate 5%, alkyl trimethyl quaternary ammonium salt alkyl trimethyl 2.5% of quaternary ammonium salt, 7.5% of bentonite, 8% of titanium gypsum and the balance of water.

[0064] Described fly ash is:

[0065] 30-50μm 30%;

[0066] 60-100μm 70%;

[0067] Described titanium gypsum is prepared by the method of basic embodiment, and in titanium gypsum, CaSO 4 2H 2 The content of O is 84.8%.

[0068] The preparation method comprises the following steps:

[0069] S1, mixing sodium lignosulfonate, alkyl trimethyl quaternary ammonium salt, bentonite, titanium gypsum and 20% of the formula amount of water, stirring evenly, to obtain the mixture M;

[0070] S2. Add ordinary Portland cement, fly ash, quartz sand and the remaining amount of water to the mixture M obtained in step S1 and stir evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap