Method for producing low-carbon steel by adopting VD refining light decarburization process

A low-carbon steel and decarburization technology, applied in the field of steelmaking, can solve problems such as long time, cumbersome operation steps, and long VD refining time, and achieve the effect of stable production and rapid decarburization production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

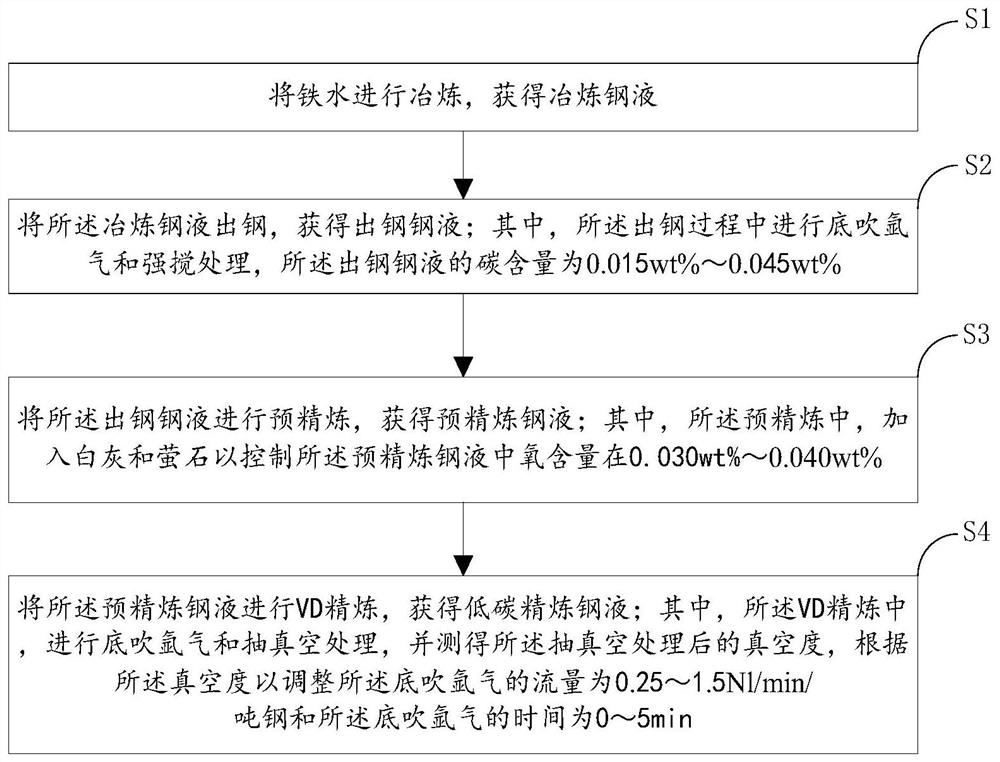

Method used

Image

Examples

Embodiment 1

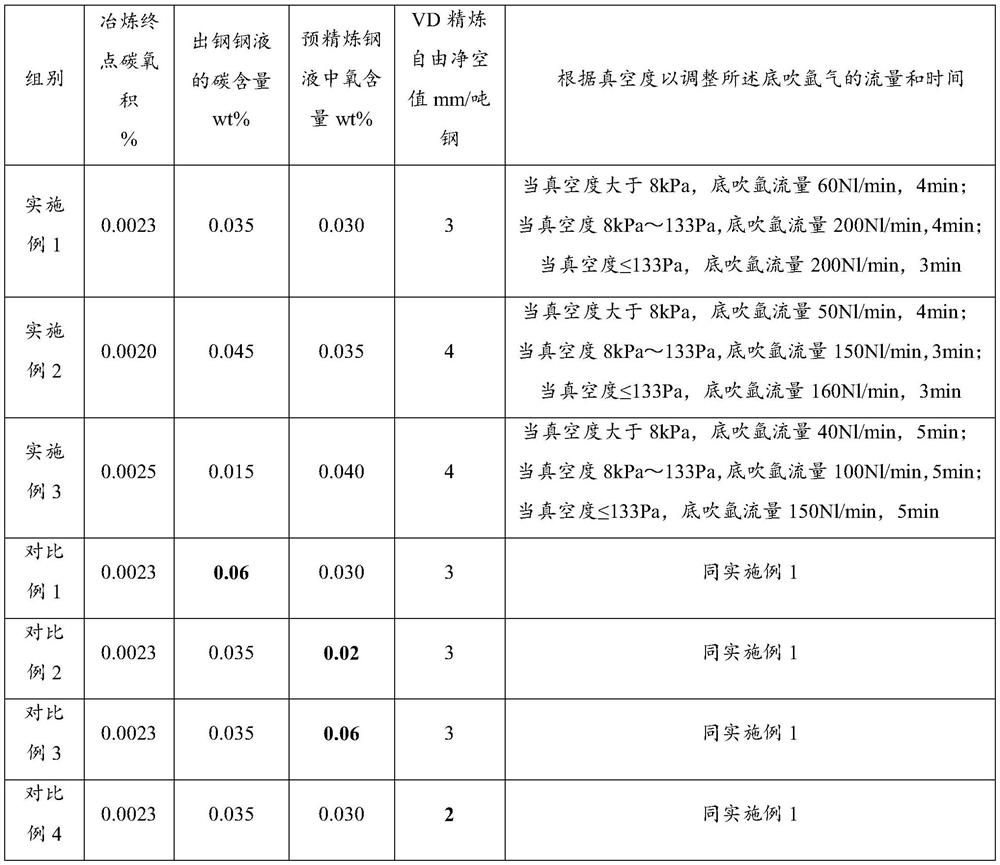

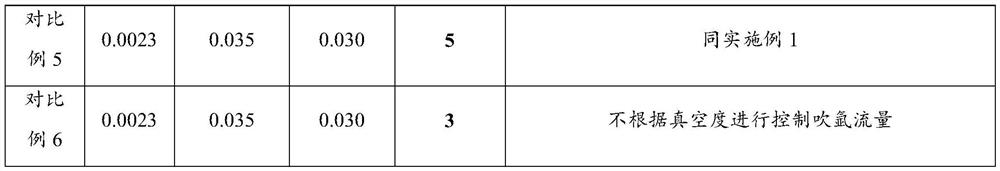

[0063] The process route for the production of DC04 steel for automobile plates is: molten iron pretreatment→converter→VD refining, the ladle capacity is 200t, and the technical parameters controlled in the process are as follows:

[0064] S1. Smelting molten iron to obtain smelting molten steel; the carbon and oxygen product at the end of smelting is controlled to 0.0023%;

[0065] S2. Tapping the smelting molten steel to obtain tapping molten steel; wherein, bottom blowing argon gas and strong stirring are performed in the tapping process, and the carbon content of the tapping molten steel is 0.035wt%;

[0066] S3. Pre-refining the tapping molten steel to obtain pre-refining molten steel; wherein, in the pre-refining, add 800kg of lime and 100kg of fluorite for tapping pre-refining; the oxygen content in the molten steel before VD refining Controlled to 0.030wt%;

[0067] S4. Perform VD refining on the pre-refined molten steel to obtain low-carbon refined molten steel; wher...

Embodiment 2

[0075] The production process of steel DC06 for automobile plates is as follows: molten iron pretreatment→converter→VD refining, the ladle capacity is 150t, and the technical parameters controlled in the process are as follows:

[0076] S1. Smelting molten iron to obtain smelting molten steel; the carbon and oxygen product at the end of smelting is controlled to 0.0020%;

[0077] S2. Tapping the smelting molten steel to obtain tapping molten steel; wherein, bottom blowing argon and strong stirring are performed in the tapping process, and the carbon content of the tapping molten steel is 0.045wt%;

[0078] S3. Pre-refining the tapping molten steel to obtain pre-refining molten steel; wherein, in the pre-refining, add 600kg of lime and 70kg of fluorite for tapping pre-refining, the oxygen content in the molten steel before VD refining Controlled to 0.035wt%;

[0079] S4. Perform VD refining on the pre-refined molten steel to obtain low-carbon refined molten steel; wherein, the...

Embodiment 3

[0087] The production of steel DX52D for automobile plates, the process route is: electric furnace→VD refining, the ladle capacity is 100t, the technical parameters controlled in the process are as follows:

[0088] S1. Smelting molten iron to obtain smelting molten steel; the carbon and oxygen product at the end of smelting is controlled to 0.0025%;

[0089] S2. Tapping the smelting molten steel to obtain tapping molten steel; wherein, bottom blowing argon and strong stirring are carried out in the tapping process, and the carbon content of the tapping molten steel is that the tapping carbon content is 0.015wt%,

[0090] S3. Pre-refining the tapping molten steel to obtain pre-refining molten steel; wherein, in the pre-refining, add 400kg of lime and 50kg of fluorite for tapping pre-refining; the oxygen content in the molten steel before VD refining Controlled to 0.040wt%;

[0091] S4. Perform VD refining on the pre-refined molten steel to obtain low-carbon refined molten st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com