Energy-saving prefabricated all-aluminum building wall

A building wall, prefabricated technology, applied in the direction of building, building components, building structure, etc., can solve the problems of increasing the load-bearing pressure of the load-bearing wall of the building, consuming a lot of manpower and time, and affecting the overall quality of the building. The effect of construction period time, reducing labor intensity and improving sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

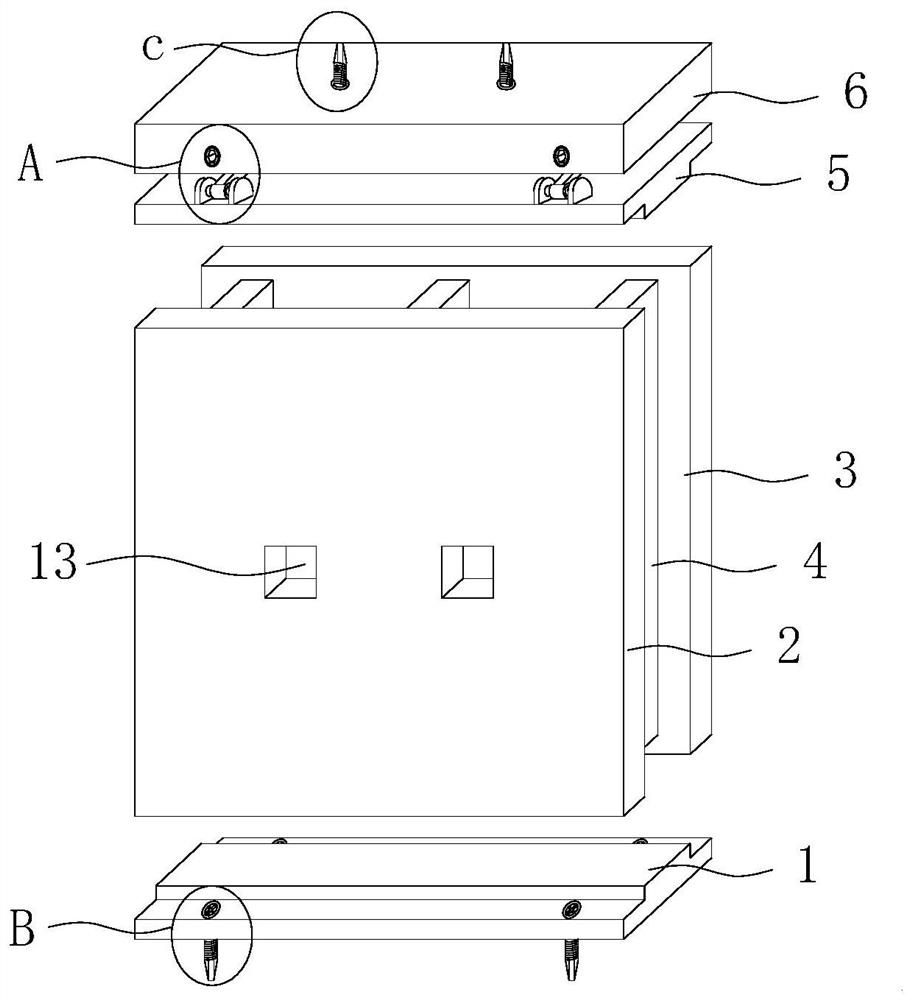

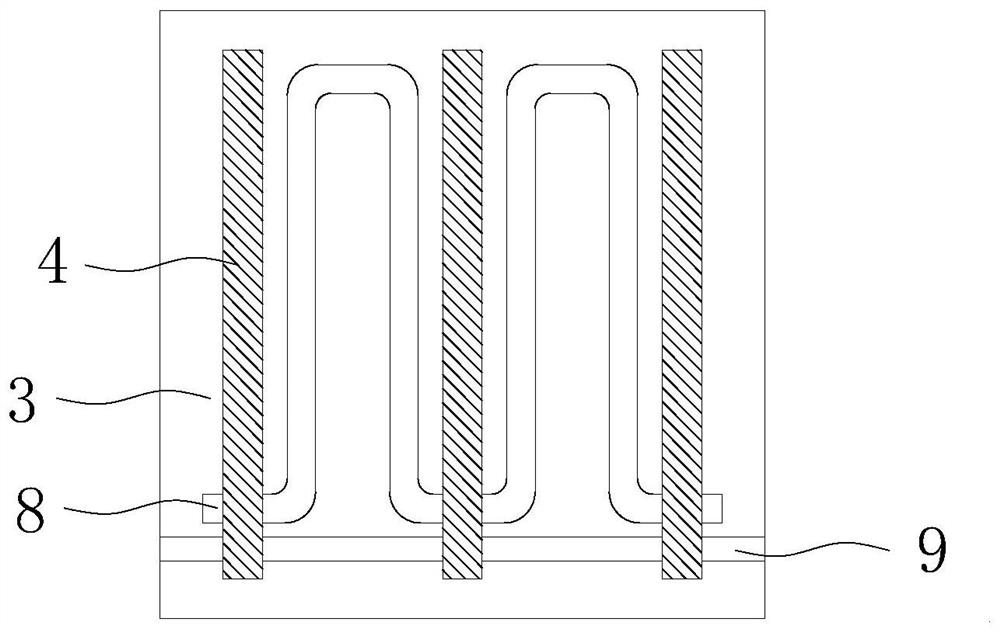

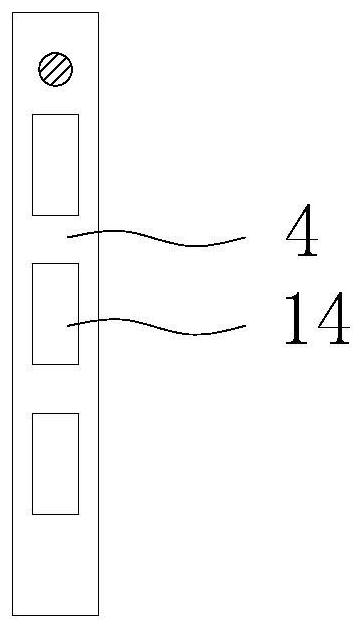

[0029] see Figure 1-9 , the present invention provides a technical solution: an energy-saving assembled all-aluminum building wall, including a fixed base 1, the top of the fixed base 1 is arranged in a convex shape, and a first aluminum plate 2 and a second aluminum plate are placed on the top of the fixed base 1. The aluminum plate 3, the rear outer wall of the first aluminum plate 2 and the front outer wall of the second aluminum plate 3 are fixed with three sets of sandwich panels 4, the fixed base 1, the first aluminum plate 2, the second aluminum plate 3 and the sandwich panel 4 are all made of all aluminum , can reduce the corrosion of rainwater on the wall, avoid the phenomenon of mildew and peeling of the wall caused by the traditional lime wall due to the humid weather, and will not cause scratches and stains on the wall due to sharp objects or other substances , make the wall look more tidy, and prolong the service life of the building. When the sound wave is incid...

Embodiment 2

[0034] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the moving mechanism 7 includes a two-way threaded rod 701, a threaded block 702, a first fixed block 703, a second fixed block 704, a fixed rod 705 and a connecting rod 706 to fix the bottom of the top seat 6 There are two groups of fixed top seat grooves 10, and the front and rear sides of the two groups of fixed top seat grooves 10 are all rotatably equipped with two-way threaded rods 701, and one end of the two groups of two-way threaded rods 701 runs through the fixed top seat 6 and extends the fixed top seat 6. On the front side, two sets of threaded blocks 702 are installed on the outer wall of the two-way threaded rod 701. The bottoms of the two sets of threaded blocks 702 are fixedly equipped with two sets of first fixed blocks 703, and the top of the mobile top seat 5 is fixedly installed with two sets of second blocks. Fixed block 704, the adjacent side walls of two groups of first fixed block 703 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com