A semi-sealed two-dimensional seepage model and its manufacturing method

A semi-sealed and model technology, which is applied in the field of oil and gas exploration and development tests, can solve the problems of model sealing failure, low production success rate, inconsistent water flow area and method, etc., to achieve sealing, increase success rate, and reduce production difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

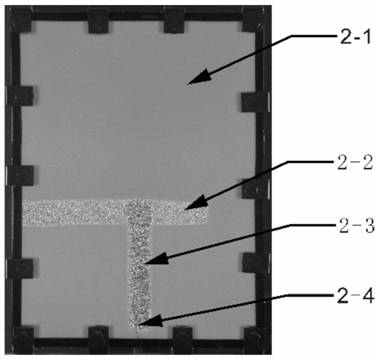

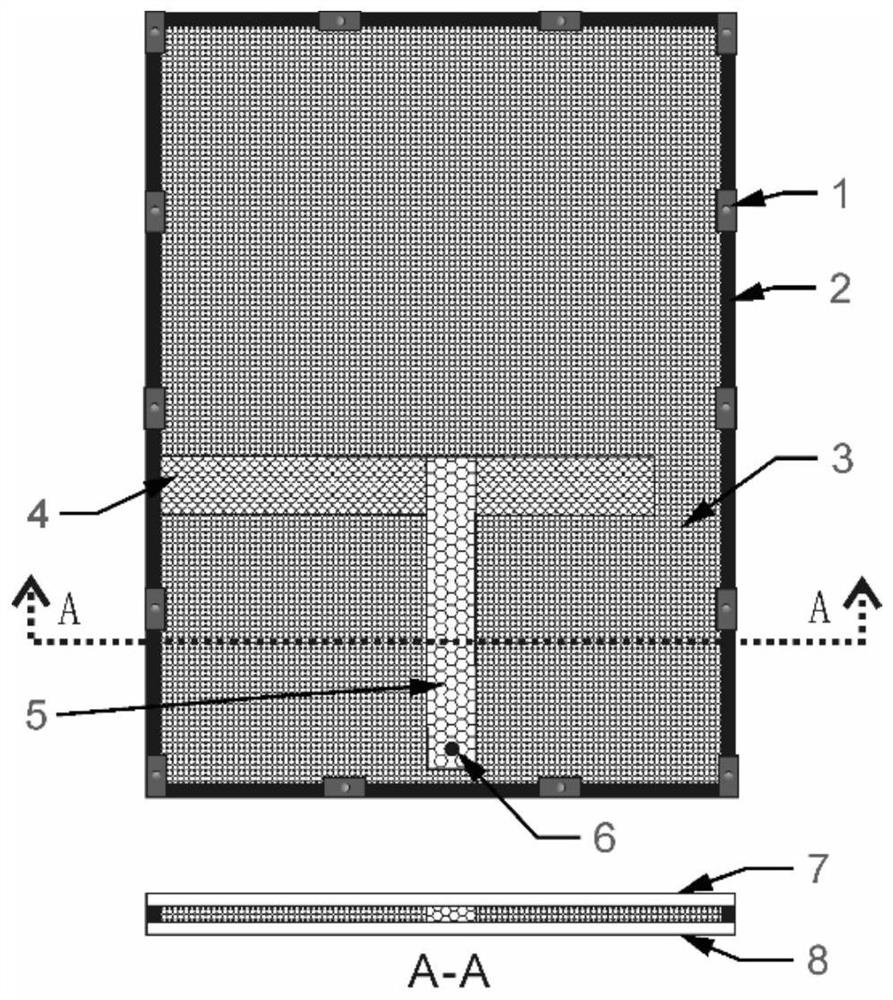

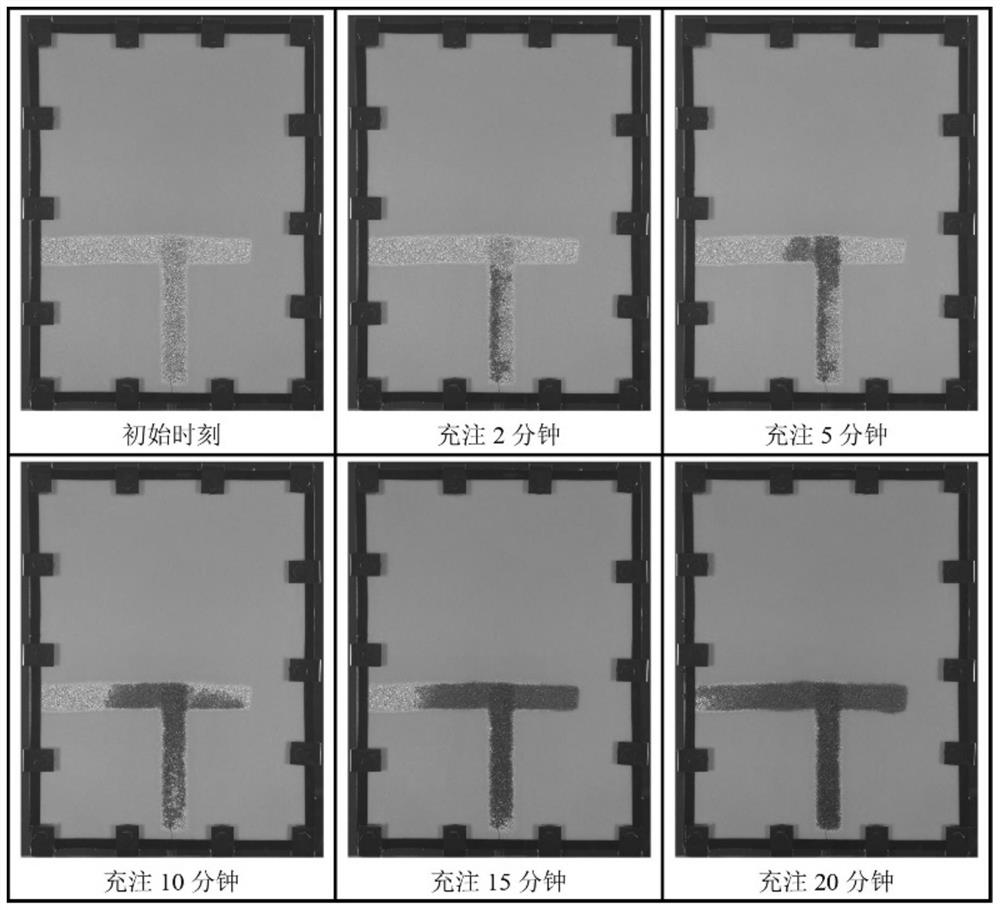

[0032] Such as figure 2 As shown, the square area surrounded by the hard sponge strip is divided into mudstone area, high permeability zone A, and hyperpermeability zone B, among which the high permeability zone B extends down to 5mm from the hard sponge strip as the model injection point, and the high permeability zone Permeable zone A simulates a vertically developed fault, and high-permeability zone B simulates a horizontal transport layer. The left side of high-permeability zone B extends to the hard sponge strip, and the right side extends for a certain distance and then pinches out in the mudstone area.

[0033] As a preferred embodiment, the upper and lower glass plates are tempered glass with a thickness of 5 mm, a width of 300 mm, and a height of 400 mm;

[0034] As a preferred embodiment, the width of the hard sponge strip is 10mm and the thickness is 2mm;

[0035] As a preferred embodiment, the thickness of the strip used to seal the seepage area is 2mm, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com