Novel piston sealing device

A sealing device and piston technology, which is applied in the direction of engine sealing, fluid pressure actuating device, engine components, etc., can solve the problems of weakening the elastic deformation ability of the O-shaped rubber ring, shortening the service life of the elastic seal, affecting the working performance of the hydraulic cylinder, etc. , to achieve the effect of long service life, improved sealing performance and strong sealing compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention is further described in conjunction with the accompanying drawings.

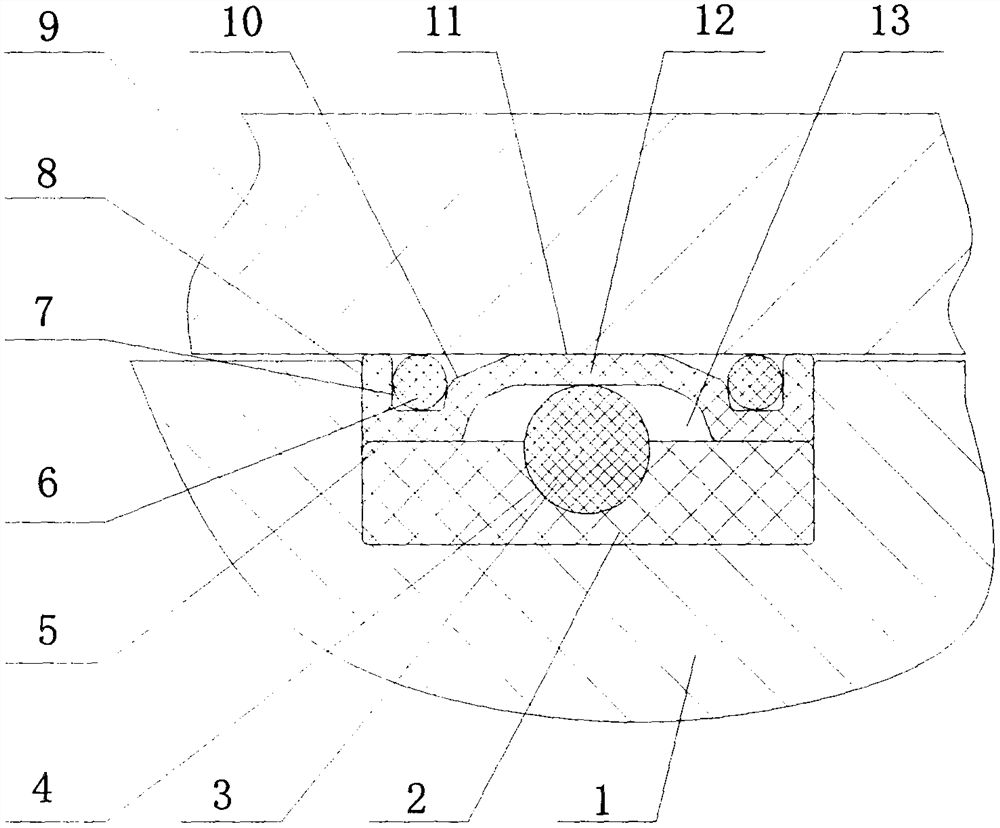

[0022] A new type of piston sealing device, the sealing device is used to seal the gap between the piston 1 and the cylinder body 9, including the elastic compensation support 2 set in the sealing groove of the piston 1, the elastic compensation O-shaped rubber ring 3, polytetrafluoroethylene Vinyl guide ring 12, two sealing O-shaped rubber rings 6, a semicircular groove 4 is formed in the middle of the elastic compensation support 2, and microscopic protrusions evenly distributed are formed on the left and right sides, and the elastic compensation The O-shaped rubber ring 3 is set in the semicircular groove 4, and the polytetrafluoroethylene guide ring 12 is set outside the elastic compensation O-shaped rubber ring 3, and the section of the polytetrafluoroethylene guide ring 12 is from left to right. The seal support section 5 on both sides and the middle g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com